Yeah, not the simple way but yeah the angle and unstack method. So I think pins make that the easiest?

Absolutely you should do this. You could make a jig for cleaving off the flutes or I guess just go ham with a cutoff wheel in a grinder.

I’m surprised there’s not an automatic solution to that kinda thing. I’ve used the Pyboxes box generator a ton for making finger jointed boxes with the laser cutter and it works great, but it’s relatively inflexible. Something akin to painted supports in a printer slicer where you could just have it auto-generate tabs in the abutting pieces would seem odd straightforward. Even if you had to give it some specific reference geometry to work off… Maybe a suggestion for OnShape or something.

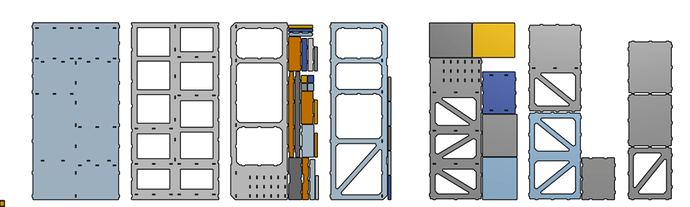

Wow - nice find on that video. I’ve had the ShopNation outfeed table/bench in my cart for a long time. But in my new home, this guy’s design might allow me to really customize my shop just right. His plans also give me a great excuse to increase the size of my LR4. Thanks for sharing.

Your bench idea looks fantastic! I especially like the drawers. I agree though, on the drawer faces it might be nice for them to be a blind tab design, but might be too thin when cut? I don’t mind the tab look on the bench itself.

And for colors, I think it should be V1E red with charcoal doors/drawers. Good branding for your YouTube posts!

Definitely interested in how it turns out.

There is for finger joints but I did not see anything for random tabs and slots.

Test cuts. I will retest on Monday but 0.25mm tolerance feels sloppy. I will check the tool diameter and make a couple more test cuts. I wanna build something so bad!

I’ve not seen anything decent for finger joints, either. Things like the box generators but they fall over as soon as you’re trying to do something a little more complex. I’d quite like something where I can model it up as you have, select the two pieces and then dimension where I’d like those fastenings and what kind. Solidworks had a reasonable fixturing tool, from memory, where you could pre-define a screw-hole in terms of countersinking/counterboring, accuracy of fit in the through-hole, thread for the threaded portion etc. and then create it in a single feature. I think that approach would be neat. If you’ve seen anything like that, can you point it out, I’m failing to find anything equivalent by googling etc.

I’m surprised at the comments about dados reducing rigidity. I’d have thought in a fully boxed-in structure that the strength is all in the dimensions that are being sufficiently constrained. Like the sheet that fits into the dado should be stopping it from bowing and then a parallel sheet somewhere else should be preventing it from racking… Then again, I have a tendency to overbuild the hell out of things so maybe that’s more of a concern with 10-12mm ply than 18mm etc.

I’m 99% sure I saw something like this last week, I can’t remember where though, where you have two pieces and tell the software that you want to join them.

I would recommend you drawer slides, fully extension, 300mm, heavy duty ball bearing, 45kg capacity. Something like:

B.R. Paolo

I love nice drawer slides. But for what these drawers will be doing the price is not work it, and desisgning for it could be a pain for other builders. The CAD can be easily tweaked if someone wants to.

These drawers will not hold much, or be used all that often. I really only need one drawer for bits but I think it will be nice to have some spares.

For me, it is the glue. Sufficient glue and most joints are as rigid as they can get. Other than like structural headers. The Dado’s are just for alignment and building mostly. Glue and some brads, call it done.

Auto sheet layout is pretty nice!

It gives a rough idea of how things fit, but does not have nesting and I can’t tell lit to skip or duplicate parts without building an assembly.

edit- probably fit this in 6 sheets maybe cut the shelves out of scrap. $120 for the table is not too bad.

edit 2 - I can just delete parts I do not want and duplicate others at the end of the feature tree to get a good idea, but nesting would be the killer feature. I will keep looking. Deepenest is amazing, just hoping there might be a built-in script.

Guessing that is an onshape plugin?

Why all the cutouts on the top surface?

Tabs for the lower cabinets to notch into.

No real reason, just good scrap squares.

Ahh I see what he is talking about now lol. Weight savings ![]()

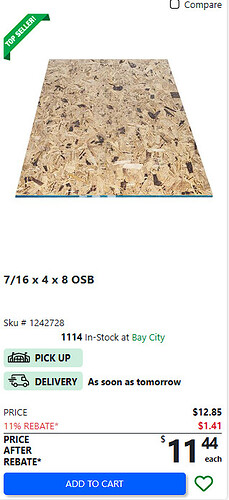

what are you using that is only 20 bucks a sheet?

OSB 7/16x4x8 is $18 a sheet

Wow I need to work more with OSB.

Ouch! $9.25 US here on the other side of the lake.