hi all ,

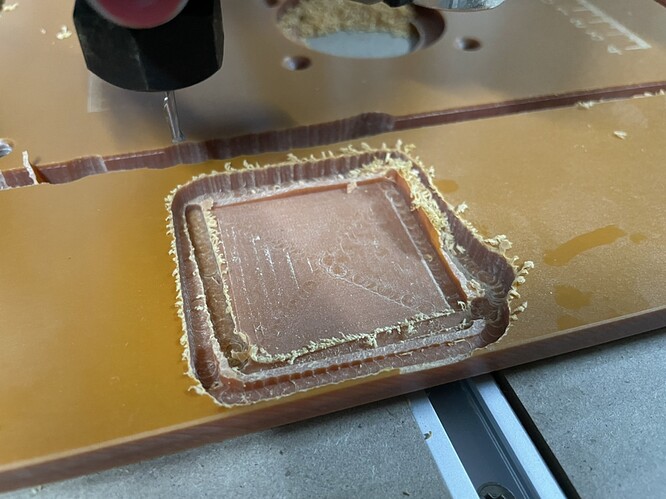

I always cut failed on full-depth contour cutting

it become crazy and trill when 2 or 3 passes and the bit will be pull in

pocket is ok , but contour cutting always failed …

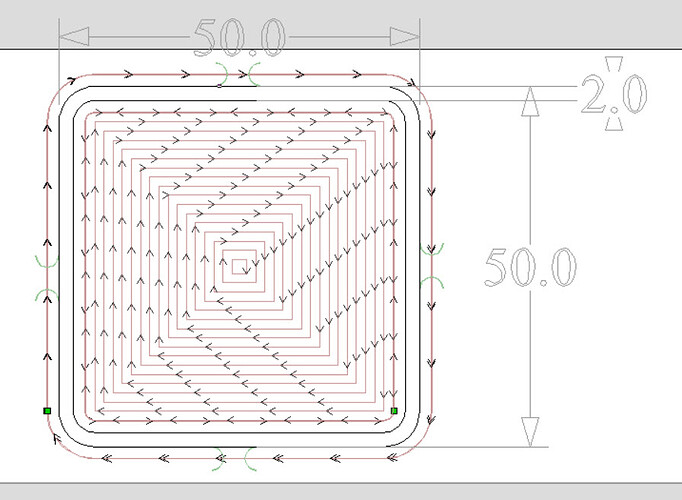

here is my test graph

and NC code

0315.gcode (73.2 KB)

Material : 8mm Bakelite (phenolic resin) ,

Bit : 1/8" single flute endmill ((1/8" Single Flute Carbide Endmill – V1 Engineering Inc))

parameter: F(xy):10mm/sec / F(z):5mm/sec / DOC : 1.6mm

(use SKR pro control lcd to change F percentage to 80%)

Spindle: Makita RT0700C (dial speed ~= 2.5 )

CAM:Aspire 10

What should I do …