Damm it.

Due to the $hit fight at work i cleaned off the computer and i am fairly sure i lost the file and defiantly the visual code install. I backed up everything but it was pretty rushed and not as clean or organised as it needed to be.

So short answer is that will not be happening anytime soon, i will have to rebuild the code while reading that long winded, bloated, rambling build log. SIGH.

So three questions.

- can i use the terminal window to just type in “G38.2 Z0” to prove there is a problem with the firmware code?

- Short of the “pain in the arse-ness” of having to set the height manually, is the any down side of just changing the code to

-=-=- start code -=-=-=-

;Project

;Created by Estlcam version build

;Machining time about hours

; code from V1 Eng

G92 X0 Y0 Z0; Set Current position to 0 on the X, Y and Z axes.

G1 Z10 F900 ; Lift off surface

M0 ; Pause for no reason ;

M106 ; This will turn on all “FAN” headers to 100%

G90 ; Set machine to absolute positioning

-=-=-=- end code -=-=-=-=-

- Can you please confirm that “M106 ; This will turn on all “FAN” headers to 100%” is correct?

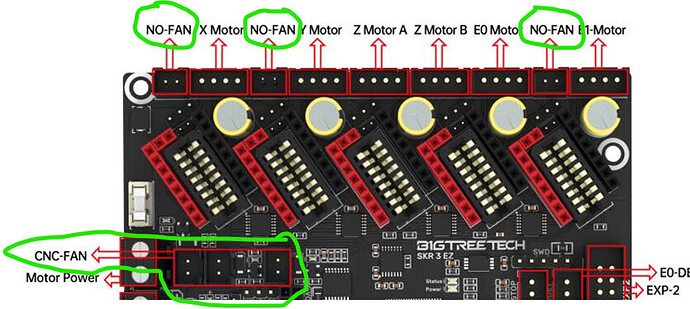

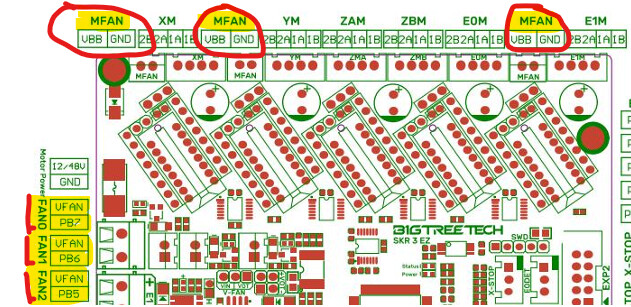

I figured out which terminals are fans on the board, its pretty clear on the manual, but there are some “NO fans” and then “CNC fans”

Which ones are controlled via the M106?

So on the manual the it also give the details of these FANS

In this post from @olijouve and @robertbu

they talk about being able to turn on all fans with just M106 and specific fans with M106 P2 255

would the fan number they are talking about correspond to the these?

Thanks everyone!