Good evening all!

So I have been watching a ton of videos, Old man coding is awesome!

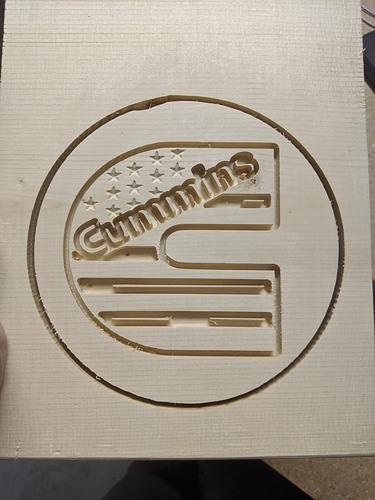

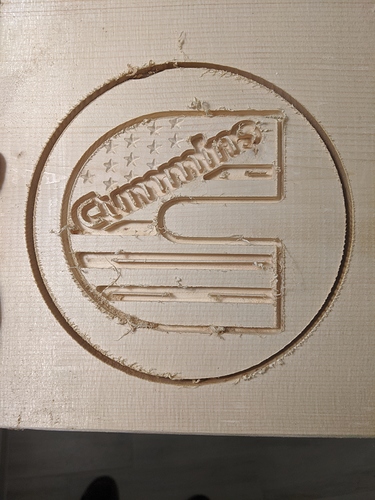

Did my first wood cut, with a tool change even! but check out my pockets, and in the top area of the circle, theres a dip inwards. I just miced my cheap chinese end mill I was using, and it came in at .112, not .125, and I had the endmill in ESTLCAM set to 3.18mm so im guessing thats why the pockets came out how they did? (ryan was out of stock of the multipack when I ordered my kit which is how I ended up with this set) the shaft of the endmill is .117 so maybe the endmill is 3mm not 1/8th inch?

any idea what caused the weird dip in the top left area?

I had set the stars to be 6mm deep, but they are super shallow, I’m guessing because they’re so small the machine is smarter than me and knew it couldnt go that deep.

I had all of the pockets and word engraving setup for a finishing pass with the endmill of 0.3mm allowance, one of the pictures is right after the machine was done and the other is after I rough sanded it

Thank you in advance for any tips/advice!