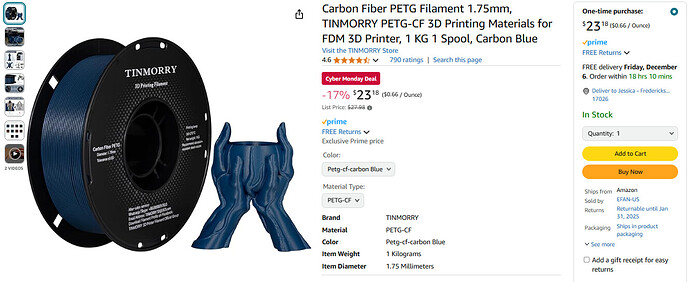

It’s just an economy filament from Amazon.

BTW I always use homemade “ABS Juice” for bed adhesion. The current batch I have I made with white ABS. So it leaves a white haze on the part of the model that touches the bed. It’s not from the filament.

The blue PETG-CF seems stiffer than PLA. I didn’t do any stress/load testing on it, but pulling and pressing on it by hand it seems sturdier and more rigid than PLA.

Also BTW, all of the 3d printing experts say “you must use a hardened nozzle to print carbon fiber and glass fiber filaments so that it doesn’t bore out your brass nozzles”. I understand their reasoning, but it seems to me that warning is a little overstated. I’ve been printing fiber filaments through the same brass nozzles for about the last 2 years (on and off) and haven’t seen any reduction in print quality. I have a cache of hardened nozzles but I never put one on any of my printers. I’m one of those people that has to see the proof of statement, you know like one of those kids that has to touch the hot stove…

I never heard of the Milo Mill before your post. I looked it up and that’s a really cool machine! However, just bear in mind once your Primo is finished you’ll be able to cut aluminum. There are some forum members that are wizards at it. A few that come to mind are @Jonathjon, @Michael_Melancon, @Tokoloshe (Trochoidal!!!)

With my Primo I was able to easily cut my aluminum parts for my LR4. After I installed an air system. A dust collector won’t work as it doesn’t clear the aluminum chips well enough and then you start breaking endmills. I copied @Jonathjon’s system and it worked beautifully!

Can’t wait to see pic’s of your build process!