I’ve been wanting a robotic sand table since I saw say the Sisyphus shortly after it came out. That desire got even stronger back in 2016 when discussion on this forum first started about a v1 version. I forget exactly who/how it started…but I do remember @Ryan coming up with a hardware design and @jeffeb3 starting what became sandify to create patterns for it.

I considered building one a few times…but really did NOT have room for one.

Well, now I have room.

I also have a table with a broken top and a partner who has ok’d me turning it into a zen table:

I’m still debating if I want to make a drop-in table that uses the same size glass the table was designed for. Or if I want to just remove the top all together and mount my own top to the legs. But I’m also having a hard time getting my head around drawing space vs. machine size, vs. glass size and how that will work out.

I went to look at Ryan’s Fusion CAD of a table sample…but that link is currently broken. So I’m just going based on the drawing on the calculator page and the calculator.

And…to really get a feel for it I think I’m going to build it as a smaller 20"x20" portable table first…then I can decide how to build it into the actual table.

I printed all the parts a week or so ago - though after taking this photo realized I had them positioned a bit wrong:

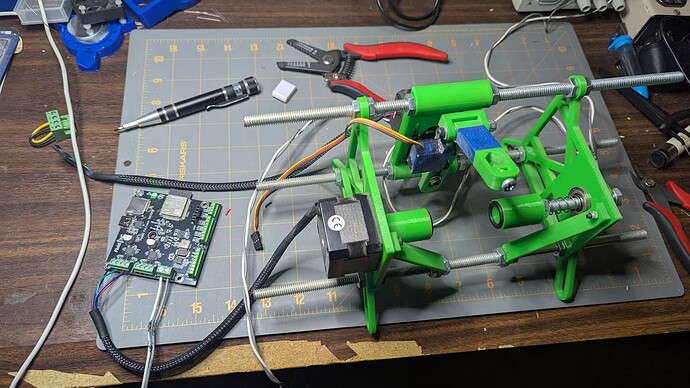

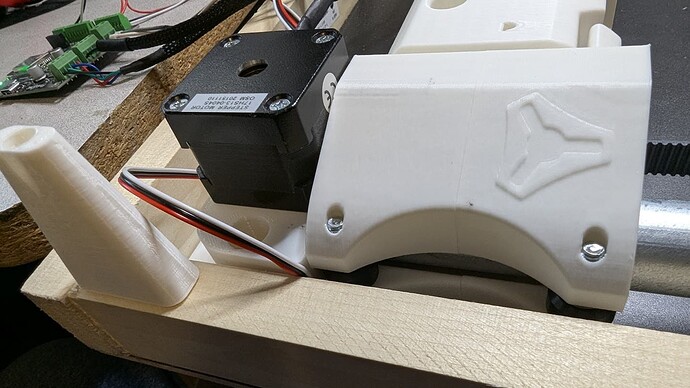

I had some of the parts on hand already - 4 idlers, the 2 pulleys, belt, most of the hardware…and I ordered a FluidNC 2 channel board which I put on my already build eggbot - which I also plan on poaching the motors from:

I ordered the rest of the parts I needed from the v1e store and USPS told me to expect them last Thursday. So I was planning on a nice relaxing weekend of building. Then USPS decided the parts should spend a day sightseeing in the LA area. Then they decided they should spend another day around Phoenix…and they really needed a day of rest after that. So delivery was delayed until today.

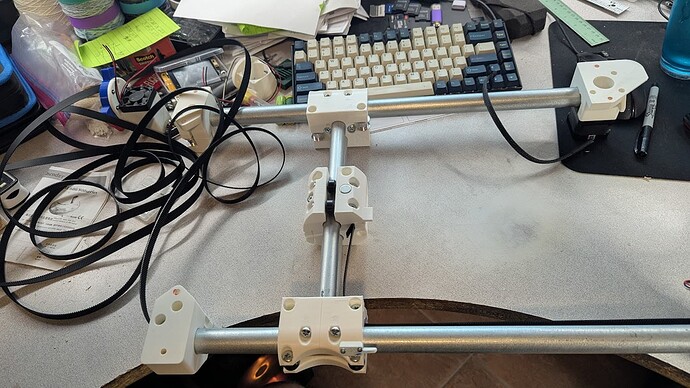

They showed up just as I got home for lunch so between bites of leftovers I was able to assemble the truck:

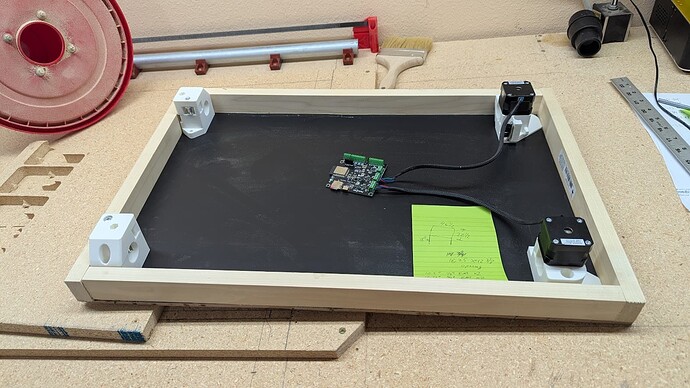

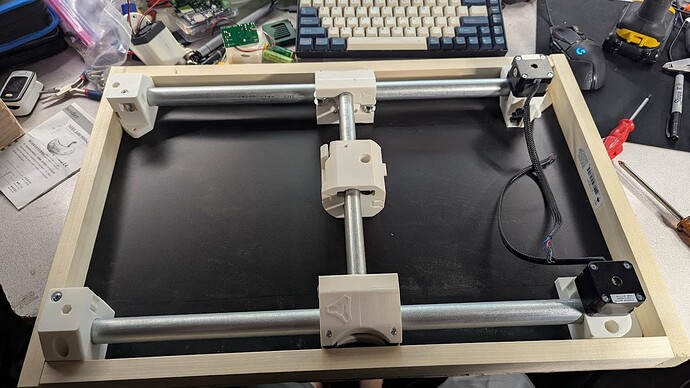

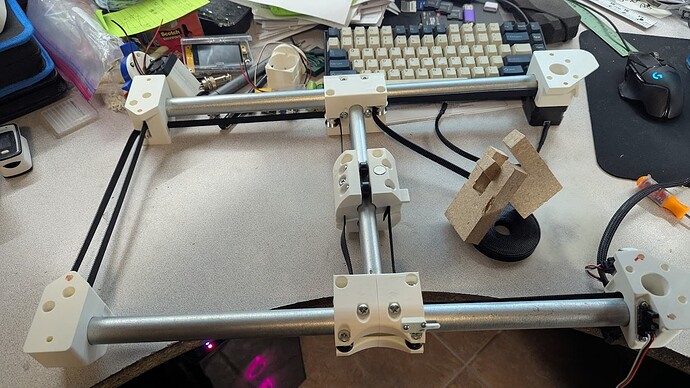

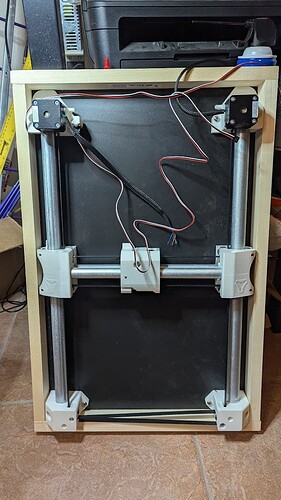

And tonight after dinner I assembled the rest of the parts:

Have to say - I’m just a little disappointed. I was hoping for a bit more of a challenge - I suppose that part is coming when I get to route the belt ![]()

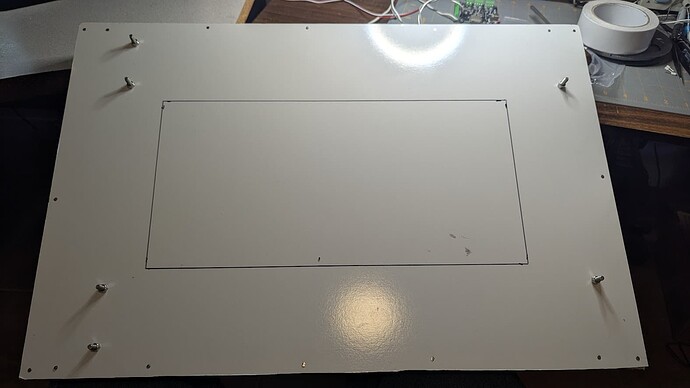

Anyway - it’s almost ready to go…I went out to the garage to see if I had any thing I could do a test assembly on - but all I have right now is 1/2" ply…I tested and the magnet is strong enough to move the ball through that…but not very well and with the extra friction of sand (or baking soda) I doubt it would work very well at all.

So - temporary hold until I can pick up some thinner material to use as a base. Debating if I can get away with hardboard/mdf or if that would be too rough and it really needs to be glass or acrylic.

Anyone who’s already build have any suggestions? For this initial build I’m not looking for a full final solution - just something that will work well enough to give me a feel for the machine and how much space I need to build it into an actual table. So I’d rather not deal with actual glass at this point if I don’t absolutely have to.

I also realized that the motors on my eggbot are much smaller lower torque motors than specified. I already mentioned this in another thread and Ryan confirmed it should be ok - as long as I keep the speeds and accels lower. Which is fine for me - I’m looking for a slow table not a speed demon anyway.

now - back to digging through my garage trying to find something thin enough to use as a temporary base …