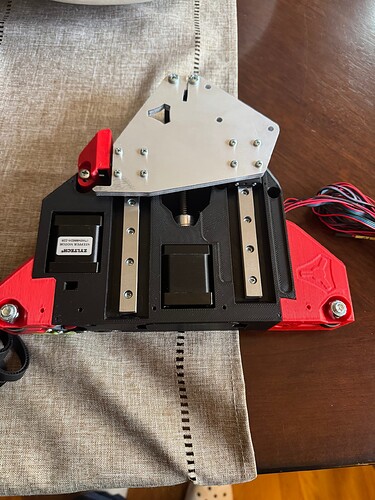

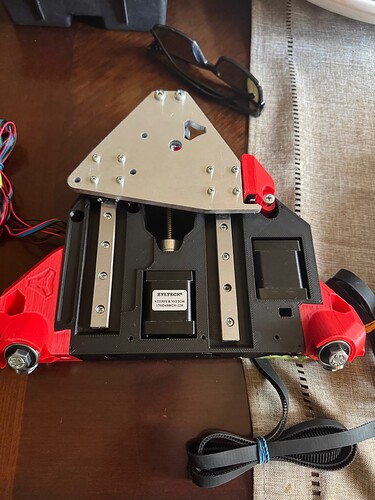

Excited to have received two boxes perfectly packaged for V1 for my LR4 adventure. I especially want to call out the team for the very clever hack to use some filament as a retention “cage” for the nuts in the core. Equally impressed by how all these parts can be printed without supports.

Congrats on getting started! Don’t hesitate to ask any questions that you have along the way.

All the brainchild and hard work of just one dude, Ryan.

Welcome aboard!

Thanks. Been here with my Primo build and really loved the building as well as using.

Made some good progress in the first phase. A couple observations and some questions?

- Very impressive design and the YZ ends are so impressively solid. I bought all of the parts from Ryan but I want to D/L into Bambu Studio just to slice and see the geometry. I never knew you could have these passages going through a print. My professional world (retired now) was designing electronic connectors for Molex for 30 years and my head is still around injection molding. 3D printing opens up such possibilities.

- Attaching the linear bearings I had a tough time as the print was nice and tight. I did strip a couple screws no mater how careful I was. Should I drill the couple out and use a screw extractor and put in a fresh screw? It seems way strong enough now.

- I thought maybe I should have chased the threads with a M3 tap. At least the first few turns??

- I just used a little green tape to cover up the Y limit switches as they did look like they were looking to snag of something

- I did struggle a little with crimping the micro-switch wires. Good idea to fold back but wire is so tiny I found better to double back to make sure it touches on the female spade connectors. Great tip to electrically verify.

- I did NOT use lock tight on the grub screws but snugged down nice and tight. Should I go back and lock tight?

Thanks!

In my opinion - yes. A little extra work now may save a lot of frustration later.

Lots of folks have seen the pulley grub screws work loose over time. My “belt and suspenders” approach is to use lightweight locktite on the grub screws, then draw a line across the end of the pulley and shaft to have a visual indication if things slip.

Agree thanks. Even thinking about I feel what’s the down size.

Also like the idea to put an index line across the end.

Re: the grub screws:

Something that people often miss is to make sure that one of the screws is tight against the flat section of the shaft. If you put both screws on the round section of the shaft, the shaft can still spin, even if the screws are mostly tight.

Thanks. I caught that in the instructions and form my past MPCNC experience. I was more concerned bout the build and once it’s this far so easy to remove one screw, apply locktite, then install and repeat. Picked up the conduit today so anxious for the next chapter.

Several of my grub screws noticeably loosened in less than nine months, with low actual runtime. Bolts holding my router mount to my core have come loose as well, despite the bits of filament. I made plenty of mistakes, including dropping assemblies and crashing. My climate is very humid.

Loctite seems like a great idea, thank you. I have never used it. I’ll do some research. It’s probably easy. I can probably grab a $5 general-purpose tube, dab the threads, and call it a day. You all are knowledgeable and helpful though, so I’ll ask.

Which thread locker would you recommend for the LR4? (I see even in Loctite “blue” or “medium” there are multiple formulations.)

Would the same thread locker be good for all parts?

I feel like it would be best to tune the machine first. Would it be easy and effective to thread lock each fastener “in-place” with the machine already assembled?

- My shed gets quite humid, often > 70%

- My shed gets hot on summer afternoons, occasionally > 90F (So far, I have never run the machine during these times. I avoid the shed when it’s that hot.)

- As you know, the grub screws are small.

- The rest of the LR4 hardware ranges from M2.5 to 5/16” (7.9375mm).

- I recall much of the LR4 assembly should be snug, but not too tight. The braces to the X rails for example seem to have a tension “sweet spot” for the smoothest core travel.

- It was difficult to run the belts last. It was much easier to place the belts first or sort of simultaneously with the pulleys, then tighten the pulleys.

If it matters, I plan to rotate/upsize my machine (or build a new one) to handle full-size sheets. I do not wish to hijack this thread. I share in case this is relevant. This operation may move to the carport, which is not fully enclosed. I’ll go from hot and humid to rainy season before this is done. Considerations include open air, moisture, storage, and any resulting loss of calibration. I imagine this changes nothing, and only makes a stronger case to apply some thread locker.

Welcome to the group. I’m sure as you know it a a very knowledgeable, active, and polite group.

I would absolutely like to see other’s respond but this is from AI as I was also curious as that’s my next step.

From Perplexity AI Pro:

For a 2.5 mm set or grub screw used on a pulley for a stepper motor, the recommended Loctite is Loctite 222 (purple), which is specifically formulated for small fasteners—typically those under 1/4” (about 6 mm) diameter. Loctite 222 is a low-strength threadlocker that prevents loosening due to vibration but still allows screws to be removed without excessive force, reducing the risk of stripping or breaking tiny screws during maintenance.

While blue Loctite (such as 242 or 243) is commonly used and will hold very securely, it may make disassembly of small set screws unnecessarily difficult, sometimes requiring heat or risking fastener damage, as noted by hobbyists and engineers. Purple (222) lets the screw be removed with standard tools, making it better suited for electronics, robotics, and stepper pulleys where future maintenance is likely needed.

In summary: use Loctite 222 (purple) for small 2.5 mm set/grub screws in high-vibration settings like a stepper motor pulley.The best Loctite for a 2.5 mm set or grub screw on a pulley for a stepper motor is Loctite 222 (purple), which is specifically designed for small fasteners. Loctite 222 is a low-strength threadlocker that holds screws securely against vibration but can still be removed easily with hand tools, minimizing the risk of stripping or breaking these small screws during maintenance or adjustment.*

Using a medium-strength (Blue) Loctite like 243 is possible, but it can make removal of tiny screws much more difficult, sometimes requiring heat and risking damage to the fastener or tool. Loctite 222 is ideal for set screws under 1/4” (about 6 mm) and is widely recommended for electronics, robotics, and applications where small fast

Hey Craig, we try to not use AI for answers to questions that anyone could just ask the AI him- or herself, trying to keep it as human as possible. ![]()

Understand and makes sense. I was just refreshing on Locktite for myself as on my list to do. I always used Blue but wasn’t sure. anxious to see other’s feedback. ![]()

BTW I remember how helpful you have been through my past experience. I’ve not been active for a while but felt good getting back to the site.

I’m going to go cut some conduit!! ![]()

You can do it! ![]()

Thanks, I do not plan on going anywhere, so I’ll try to help if I can. ![]()

After thinking about it I think I’m going to just use what has always worked, (plus I have it), the Blue Medium strength Loktite.

I do what to re-state that I like @ttraband suggestion for the index line with a fine tip marker. Makes sense to have a quick visual.

I’ve always used the blue (in the red bottle) not the red (in the blue bottle).

Locktite to use with our grub screws:

- Purple works well and is the recommended one by the data sheet.

- Blue works well and is easy to get, what many builders use.

- Don’t use red.

Wow missed that on the data sheet but lately I seem to be missing a lot. Hell getting old ![]()