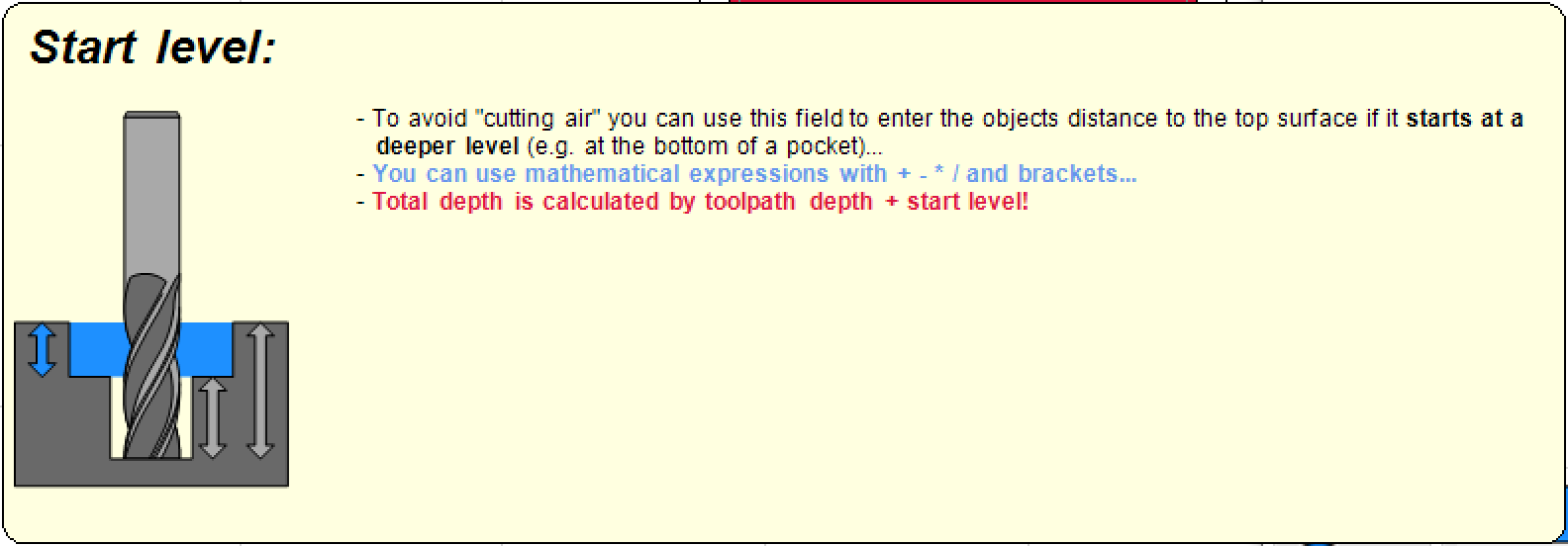

I Cut a “holder” for these wooden bones, that are thicker than the holder. You can see my zero-point on the holder in the lower-left corner. Using the dual end-stops, I can get this in the exact spot every time I use it. The bones will be of various thicknesses, depending on the wood I use. Using the digital caliper, I can measure the height difference. I planned to put this into the starting height field of Estlecam as a negative number so that it cuts at the right elevation. I only want one mm off the top of the bone, which is standing 3mm proud of the holder. The pop-up help seems to indicate that I can use simple math, which implies to me that it will take negative numbers. But, it won’t take anything less than zero. How can I get Estlecam to cut above the z-height?

Estlcam is a little confusing there. If you want to start at -3mm you put starting depth “3mm” (distance to the top surface).

Using math means you can do calculations like 20mm - 15mm = 5mm starting depth.

I was also confused at first, but he has got a video for it as well on youtube where I looked that up, but I can’t find it at the moment.

If the bones are flat just set you Z 0 to the top and take your 1mm off? That is if you are using the pocket as a jig

Or the bottom of the bone hole is bed 0 and the thickness of the bone is entered will then will cut the 1mm. Same here the screen you are showing is to cur a pocket in a pocket without air cutting

IIRC, it starts that much further down, and then the depth is added. I’ve used it when I cut out a pocket and wanted to carve inside the pocket, but I accidentally thought the depth was from the top.

What about just setting Z=0 at the top of the new workpiece?

I start every job with zeroing the Z. Since I have the dual end-stops, and I need X and Y to “home” in the same place every time (not over the work), I think I’ll just need to do the z-home first, then home x & y, and without doing a z-home in the job start, I should be good to go. I’ll give that a shot.

Okay, so that didn’t work. I was cutting air. What did work - I put the z-stop on-top of a 7mm platform, above the bone template/holder. I took that added thickness into account in my cutting depth. Since the platform sits 4mm above the “work”, I set my cutting depth to 5mm. Worked great, and that will be my solution going forward with these.

Looks great glad you got it sorted

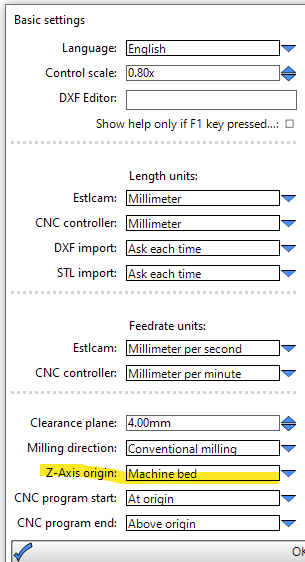

If anyone stumbles across this years later like I did. The answer to this problem is go into the basic settings for Estlcam. Then change the z-axis origin to “machine bed” instead of “workpiece top side”. When you go to create the g-code, it will ask for the workpiece thickness and you can enter the offset from your home to the top of the piece.