I did a carving job yesterday using an STL file and the latest version of Estlcam. 12.072

Estlcam estimated about 1 1/2 hours for the job, but I knew that couldn’t be right.

The first part, the roughing schedule lasted just over 1 1/2 hours and the finishing schedule took another 5 hours to complete.

I looks like possibly only the first schedule is being shown.

Carves are often waaaay off, especially text. I don’t know why though. ![]()

Does ESTLcam count z-raises?

I have find that also others CAMs doesn’t give proper estimated times.

But a 5 hour difference is a bit much don’t you think? Makes it impossible to use for anything at all, especially if wanting to use as a costing element.

That part doesn’t affect me, but still my time has to be organised.

yes same problem here. I usually make big engravings with lots of lines. I haven’t dived into all the ESTLcam settings yet, but it might help something if there are settings for the simulation and travel speed. Non cutting traveltime could easily add much time in big engravings.

I have find out that. In our workplace where we use CNC-machinetools everyday. Some machines are faster than estimated time because they have much faster travel speed than CAM count. And also some machines are much slower becauuse they have much lower travel speed than CAM counts.

@christian-knuell the maker of estlcam does check in here from time to time, perhaps they have some insight?

The estimates probably don’t account for acceleration in moves in addition to what others have pointed out. On my router, sometimes I hardly ever reach max velocity with low acceleration rates trying to avoid missed steps.

I have started another carving today and just finished the roughing pass.

Estimated time was 1 hour 51 minutes total and that was about the time the roughing pass took. The finishing pass has now started and is estimated at 8 hours19 minutes.

It looks like the finishing pass is not being calculated at all in the total time.

I shut the job down at about 5 hours in of the finishing pass. 3 and a half hours to go.

The reason was that I am very disappointed with the results.

In places the roughing pass cut way too deep making the finishing pass look awful. I am still not happy with the finishing pass surface either, it does not do a nice finish like I have had with similar jobs in version 11.

I may try again using 11 to see what the difference is like. but that means another full day of machining.

You are also using Estlcam as the controller, do you?

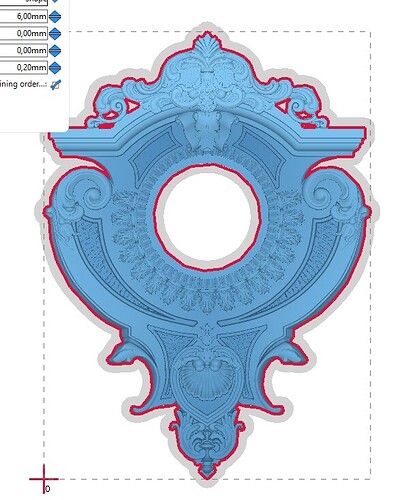

I am having the same problem with carves and only when Ryan asked me why my Z moves were so slow I started thinking that something might be off. And it indeed is:

If you have XY at max speed 3000 and Z at 1200 for instance and use a tool with 3000 speed, Estlcam has to recalculate Z for every tiny step and brakes to 0 for the tiniest fraction. That’s why carve movement is so slow then.

You have to match the tools speed to the slowest axis while 3D carving, then it will be a lot faster.

From the German thread at Estlcam Carven stockt und braucht lange - Estlcam - CNC-aus-Holz

So basically faster is slower. ![]()

@christian-knuell This should be a very big tooltip/warning somewhere, the way it asks you whether you want to set a higher depth when carving.

@vicious1 Thanks for making me question and research this. I am going to cut the sign for Peter again and compare times. ![]()

It is indeed the solution. My carves are so incredibly fast. Set Z to 2000mm/min. ![]()

I will give that a try next time and I will not allow to cut deeper either as I feel that could be the reason that I had damaged roughing cuts in places.

I need to get some more material before I can do another test and that is a bit hard being in a small country town.

Just try it with air cuts. Speed can be seen immediately.

What happens if that speed is in excess of the machine capability?

If I force a too high a speed I will get stalling and lost steps, or have I misunderstood something?

While discussing this type of carving, is there anyway that I can use the outline of the model to do some extra work, like doing a clean-up pass or cutting deeper along the red line?

Your Z should match the max possible of your machine obviously. ![]()

In other words, the X,Y Tool feedrate should be equal to (or less than) the controller Z Maximum (no lost steps) feedrate. It sounds like Philipp and I were both able to increase our Z Maximum feedrates (mine was low because I had no limit switch), but it sounds like machining time will decrease even if you have to lower your X,Y Tool feedrate to match your Z Maximum feedrate.

…A 2D DXF mask would seem like the best cleanup option, but the 3D Convert to 2D might produce something usable.

The gain of machining time is substantial, because you have the cleanup operation anyway that you can run at 3000mm/min and then the bits that are actually being carved will be done quickly now as well instead of taking several minutes. It’s really great I finally figured that out. ![]()

Hello,

machining time is only a rough estimate in the CAM as it does not know the actual machine capabilities (acceleration, axis feed and step loss prevention limits).

Only the Controller can know how long it really takes (Estlcam controller shows the time to the next stop quite precisely - but the CAM does not ask the controller for accurate times as it is not used by everyone or running on a different computer)

If there are a lot of accelerations and decelerations or the feeds need to be reduced due to axis limitations the estimates can be way off - carves and 3d machining are very typical for this scenario.

If most of the work is continuous movement the estimate is pretty accurate - linear pocketing and large workpieces are typical for this.

Christian

Thanks for chiming in. The most important piece of advice for carves is: don’t set the speed higher than your Z max speed. ![]() You explained it very well in the German forum (see above).

You explained it very well in the German forum (see above).

Did you notice that this holds also true for the round tabs? They actually lose you speed if you are cutting above the Z speed (which you usually do), the normal tabs are kind of better for this then.