Hi,

Thought I would share a project I am close to finishing. A sliding barn door controlled by a stepper motor, a TM2209 FYSETC 3.1 (should work with any 2209) , an ESP32CAM, a 12V power supply, 12V to 5V solution and some jumper wires.

Stall guard might not be enough for precise and consistant positioning, but seems to be good at stopping a door when it gets to the end of it’s path, or stopping when colliding with someone. This is the basic concept behind this. Very silent too.

From working with the ESP32 CAM it is certainly capable of driving multiple 2209s using one wire UART mode, you could in theory have a version of marlin running on one. Very powerful little device.

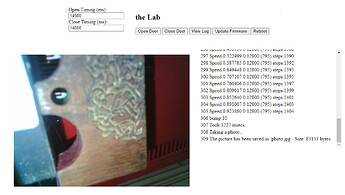

It has a web page that you access via barndoor.local, put in your SSID and password at the top and program the ESPCAM32. The web page has buttons as shown below, open door, close door, update firmware, refresh. click on the pic to take another pic, wait and refresh the page. (will get around to something better, not javascript guru.). This is not using steps, but a sin function to control speed, it does the homing thing at the end. This needs to bump into something at either end, if not it won’t work properly, but barn doors usually have a bumper on either end.

Arduino code: (Needs some common downloaded libraries.)

Pretty new must say: (new html stuff, can go to X)

BarnDoor1.5.zip (8.9 KB)

Even Newer than that Version: (adds limit by steps)

BarnDoor1.4.zip (8.1 KB)

Newest Version: (Adds progress bar for OTA and mis tweeks.)

BarnDoor1.2.zip (7.5 KB)

Newer Version: (Adds json communication of settings.)

BarnDoor.zip (6.8 KB)

New version: (Adds log to the web page, misc tweaks)

barndoor.zip (6.5 KB)

Original

barndoor.zip (5.5 KB)