LOL, the front is open, and the bed does have some free space around it… Maybe conveyor belt, or solenoid actuated part scraper, or maybe just design the fan Duct and Core to be sturdy enough, with sturdy fender/snow-plow front face to knock cooled parts off? Conveyor with out-feeder would be cool for infinitely long prints.

That plus the enrage rabbit carrot feeder (or MMU) continuously feeding filament, plus some AI Fluff up detection seems useful for a print farm…

And given "Voron 2.4’s Z gearbox. A 16T pulley and an 80T pulley are coupled with a belt to provide an 80:16 gear ratio. " from Kyleisah on klipper forum

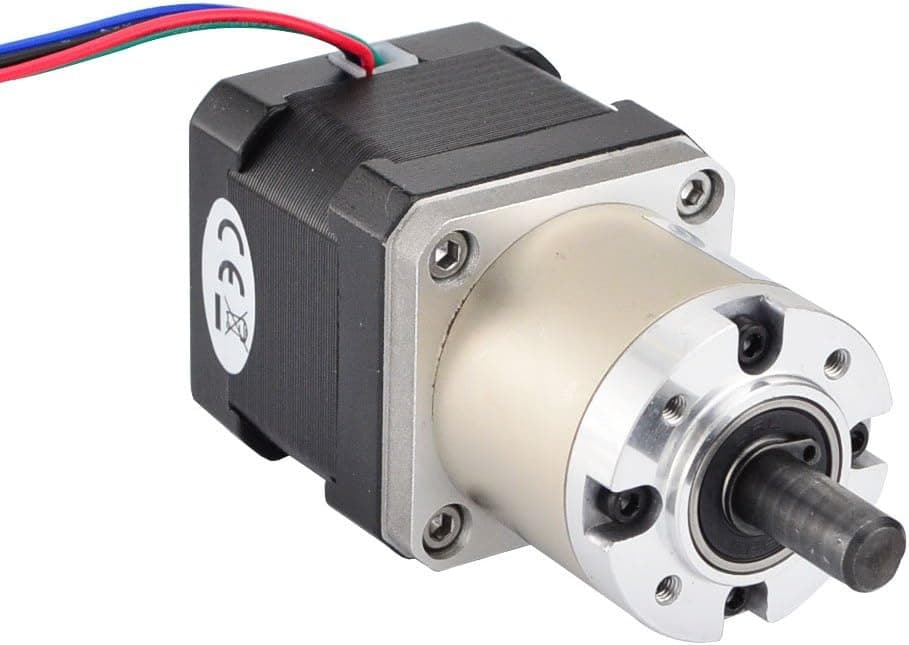

Maybe cheaper bulk bought flying Z Stepper with planetary gearbox with low ratios, e.g. 4:1 maybe?

Individually low (so z hop doesn’t suffer), but high enough resistance when 3 are used together to resist violent drop of a ~4lb bed, ‘slow’ drop seems ok.

Special steppers might seem expensive, until you’ve killed a Controller board or 2… And weighed up pros/cons reliability/corner-cases/assembly/aesthetics of other alternatives? Hopefully something with less quirky ratios exist than this $40 0.067° step angle Stepperonline exist.

Or some 5:1 gearbox bolt-ons?

First search hit was this, I didn’t look at backlash specs, or shop around for better quality-price. Minor Z Stepper mount mod required, chamber has room. Aesthetically nice imo.

Guessing worm gear would be safest though, especially if planetary low ratio gear boxes are not resisting motion enough. Even if the plate falls slow-moderate speed, the geared stepper may still spin fast enough to create board killing back emf.

Still unfluffing my printer. I will make Klipper 12 work. Updating/cleaning up my personal notes on configuring Klipper with CAN Bus as I progress. This CAN Bus video and doc link that @Jonathjon shared is helpful, and his printer.cfg backup.