Hi all, I have my Primo all built and working perfectly with the pen. I’d really like to start getting into foam and wood carving but friends that own CNC machines warned me to have a good vacuum system. I could help but notice there really are no Primo dust shoes for the Makita. I’ve searched the forums along with Thingiverse and maybe found one or two that haven’t been completed or updated in years. Am I better just standing there with vacuum hose?

Well, we do say that you should never leave your CNC unattended, but a good dust collection system is certainly nice to have. Foam is difficult to deal with “in the wild” as well, so collecting it at the source is definitely good.

Dust collection with the Primo is tricky, because the router’s motor cooling exhaust blows right into the work area. Normally, this is good, because it clears chips away from the bit, but it’s not so good if you want to vacuum them up, since the volume of air often overpowers the vacuum, an you get it just blowing stuff all over the place anyway.

There are several dust collection shoes available, but most of them take away a few inches (at least) of working area from the CNC, which I’d like to avoid myself. Keep looking around the forums, they are here.

I tried cutting polycarbonate on the weekend and got mountains of workshop glitter everywhere despite my best attempts at holding the vacuum near.

I found this post: [Dust collection without shoe...futile? - #32 by robertbu ] which is working on a solution that would not cost you any x or y but like you I have a Makita and that thread seems to have gone cold.

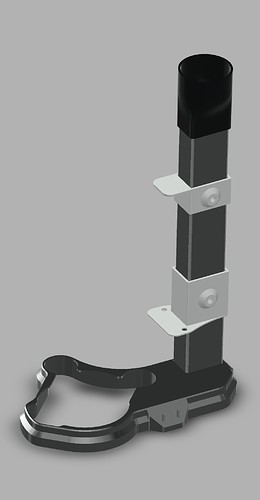

I am currently prototyping a boot I made for that system for my Makita:

But I’m only at the fitting stage, I still need to test it with chips flying to see if that air exhaust @SupraGuy mentions is a bane or a boon.

I should have some preliminary results this weekend.

As an addendum, this design maintains clearance in all axes at all extremes (I’m on prototype 3 for this reason), you don’t lose any x y or even z provided you have an endmill of non-zero length. It also doesn’t interfere with z-axis motion, you set it to the top of your stock. Unfortunately it doesn’t allow you to easily see the tool while in use which can be a show stopper for many.

It does include some changes to the original tube and you’ll need to grind down an M8 to a 4mm pin so a drill press/grinder combo would be good if you have it. I expect to be able to share it by this time next week.

Definitely wasn’t planning to leave it unattended. I’ve just read a lot of things stressing the importance of dust collection. Especially if working with MDF. Maybe the alternative is to just build an enclosure that keeps the dust in one place?

@agryson, I’m starting my build in the near future. I’m using a Carbide router (Makita clone). I’m looking into dust shoe options early on and came across this thread. Did you continue moving forward with your design? Thanks!

I used one I found on thingaverse.

It has magnets you can attach a brush adapter to help. I have found it does pretty well even without.

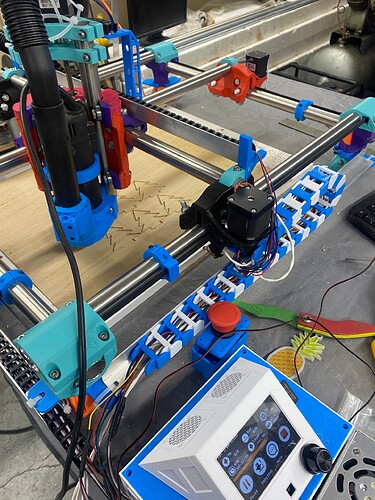

Is something like this what your after

That hanging shop vac is hilarious!!

Nice job

I thought it was a good way to have not much force on it for the machine to make in un accurate.

Works good and it’s out of the way hahah

I found a pretty brilliant one on printables where you only lose 5mm.

https://www.printables.com/model/244558-dust-collector-for-mpcnc-primo-with-makita-router

@agryson, I came across this thread when researching dust shoes for my upcoming build. I’m also using a Makita (well, Carbide) router. I think I saw your concept in a couple threads. Did you end up testing it out / moving it forward?

[quote=“Philipp, post:10, topic:28300, username:Tokoloshe”]

I found a pretty brilliant one on printables where you only lose 5mm.

[/quote] I love the concept of that one - let me know if it works! ![]()

![]() -

-

I wonder if the vertical channels could be “backless” so the router body would be in the middle of the airflow. ![]()

If you made them like that I guess the dust from MDF for example would find its way inside the router.

The way it is works really well.

You have it working? Cool!

On the LR2 I have a little insert that blocks off the exhaust in the bottom of the router and redirects it above the work surface - only a couple of hours running in foam so far, but that really stops the dust blowing and gives the vac a chance to pick it up. MDF next week will tell.

Then I suppose I can be the ten thousandth person to try something different on the LR3 OR, I could just use this one or a remix.

For quite a while now: MPCNC Primo Schneewittchen - Oldenburg, Germany - #153 by Tokoloshe

![]()

Ahh yeah, August. I think I was somewhere near Groningen when you posted that - I could have just popped over and inspected it in person if I wasn’t having an absent patch! ![]()

![]()

Nice.

You are always welcome. ![]()