The shoe portion of the design is still very much in flux and prototype-ish, so it will be a bit before I will share the shoe. But everything else in the design is stable and works well, so I can share it now so that other can play with shoe ideas if they like the rest of the design.

Note:

- I’ve done a bunch of cleanup and made some mods since the last time I printed this shoe, so test slices to test for fit might be in order.

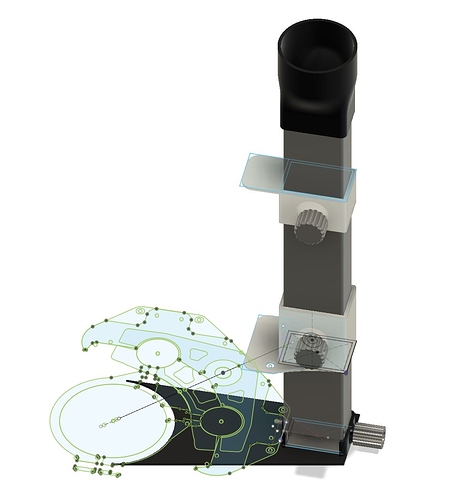

- There are reference drawings derived from mesh slices of the Primo parts.

- The attachment pin is a #8-32 2" machine screw where the threads have been ground off all but the upper 6mm. It was one aspect of my original design I was nervous about, but it has performed well…even when I’ve made mistakes and driven the shoe into clamps.

- I’ve included a piece of a shoe to show how the attachment mechanism works.

- The tube parts will print on a Prusa i3Mk3 on the diagonal. I have 135mm of working space on my Primo. Shorter working spaces can use a shorter tube.

- I glued the brackets to the core using Barge contact cement. I though I’d go through a few designs and wanted a glue connection that I could remove, though the glue job has been plenty strong for ongoing use.

Fusion 360 file: Dust Boot Partial.zip (2.4 MB)