I like these ideas. I’ve been contemplating the question of belt stretch and what might reduce it. There are already enough ideas out there so I won’t add more but one thing I will point out is that the effect of belt stretch changes with position.

The stiffness changes with length because a given force will stretch the belt by a certain percentage. Near one end, you will effectively have a short belt to one end and a long belt to the other end, and most of the stiffness is contributed by the short belt, whereas in the middle, you have two medium-length belts and the stiffness of two medium belts could be lower than the stiffness of one short belt.

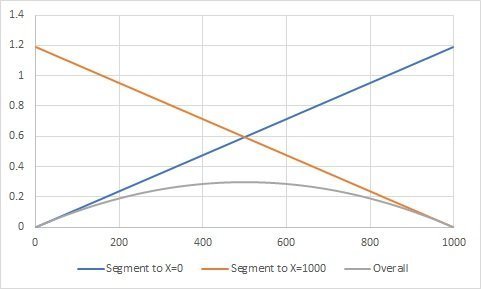

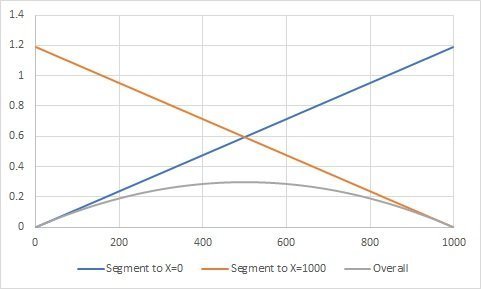

I measured about 4mm stretch on a 1220 mm length at 5.5kg of tension, or a stretch ratio of about 0.0006 (i.e. 0.06 percent) per kg of tension. This is for a 6 mm belt. Under 2kg of tension, considering each segment separately, the segment from X=0 to the tool has length = X and the stretch is 2kg * X mm * 0.0006 per kg. If the table were 1000 mm long, then the segment of the belt from the tool to X=1000 would have length (1000-X) and under 2kg of force the stretch would be (2kg * (1000-X) mm * 0.0006 per kg).

To calculate the combined deflection of both belts, the question is, under what deflection is the combined force equal to 2 kg. I won’t derive it here but the combined deflection is 1/(1/d1 + 1/d2), where d1 and d2 are the hypothetical deflections of each belt individually.

The outcome is shown here for a 1000 mm travel and my 6mm belts that stretch by 0.0006 per kg.

[attachment file=114955]

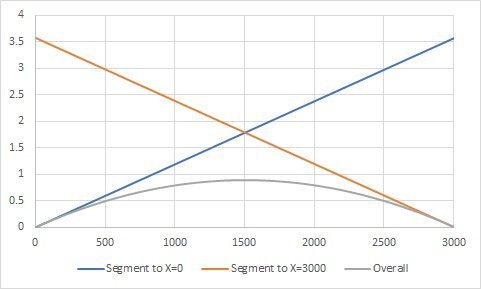

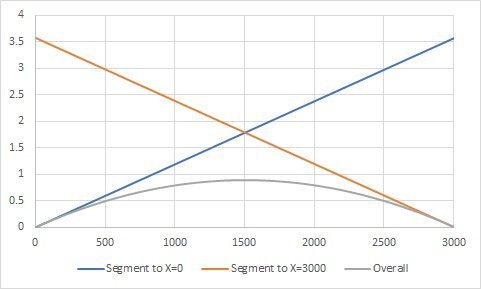

For a longer table, say 3000 mm for LR2, the same formulas produce higher worst-case deflection:

[attachment file=114956]

Also note that these assume a perfectly rigid mounting at both ends. If there is some stretch in the anchors then the orange and blue plots would be shifted upward by the amount of deflection at 2 kg.

I tried measuring this nonuniformity of stiffness and I did find it was slightly less stiff in the middle, but the numbers didn’t exactly reflect the theory. But then there were other things deflecting at the same time and I wasn’t looking for a quantitative confirmation.

Also, the position of the tool in the perpendicular direction has an effect. Near one end in the perpendicular direction, one belt is supporting the majority of the load, but when the tool is in the middle, both belts share the load equally and with half the load should come half the deflection. I also tried to measure this effect, but the results were inconclusive. I am not very skilled at taking these measurements and my setup is pretty janky.

I bought some expensive name brand belts but I have not yet measured their stiffness. I am hoping they are not much better because it’s simpler for everyone if it doesn’t become another variable.