Oh. It really is just a dangerous version.

Well ok then lol. I had no idea that was a thing, or even needed lol.

yeah, I had to google it. I am just starting my learning of klipper and am nowhere near good at it. I know about enough to set up my config and about it. And only if I can follow examples and adjust accordingly. But some of these guys are just next level with the python scripts that run klipper functions.

I’m going to have to mill an adapter plate to mount the new extruder to the mount on my printer.

It’s nothing really fancy. Mostly just a 1/4" thick plate with holes in it. I threw it into CAD last night and will make it tomorrow.

I found that link with a pretty easy google search. Still not sure what the real benefits are.

Me either. Probably because I’m not a “DANGER” user LOL

It’s Klipper without Kevin’s feet dragging of updates and feature requests. ![]()

Klipper’s default pid tune is flat out wrong. Is one example.

Can you elaborate on that? Not at all saying you are wrong I’m just curious.

Also how dangerous is dangerous? I know how to use Klipper but I am by NO means good at it. So I’m not sure your version is something I should be dipping my toes in or not LOL

I have only ever used klipper on my printers. My current setup is Manta M8P with CB1, the H2V2S revo, and it’s a dream to make changes and tune. I have the BLtouch and it’s super easy to program, my config is below.

[bltouch]

sensor_pin: PD13

control_pin: PD12

probe_with_touch_mode: true

x_offset: -28.2

y_offset: -36.69

[homing_override]

gcode:

G28 X Y

G0 F3500 X150 Y185

G28 Z

G0 F3500 Z15

_cztilt ####### this macro runs z_tilt_adjust only if it needs to

G0 F3500 X150 Y185 Z15

G90

axes: Z ####### Ony affects z axis (or all axes) homing

[z_tilt]

z_positions: 31,70 #z

295,70 #z1

165,327 #z2

points: 31,70 #z

295,70 #z1

165,327 #z2

speed: 350

horizontal_move_z: 5

retries: 10

retry_tolerance: 0.04

Happy to offer any help if needed!

d

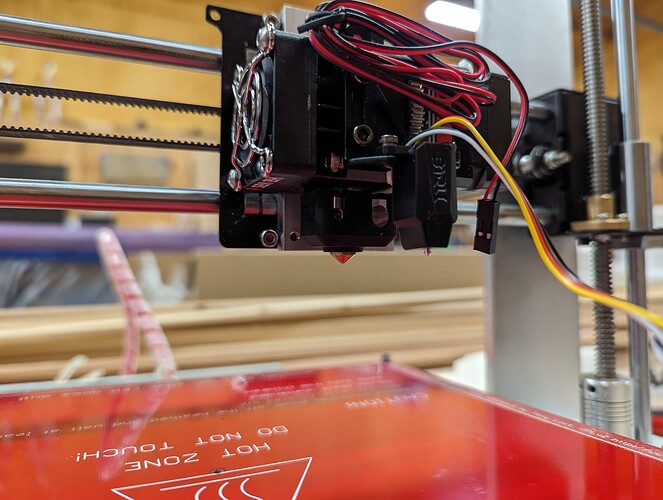

Step one complete.

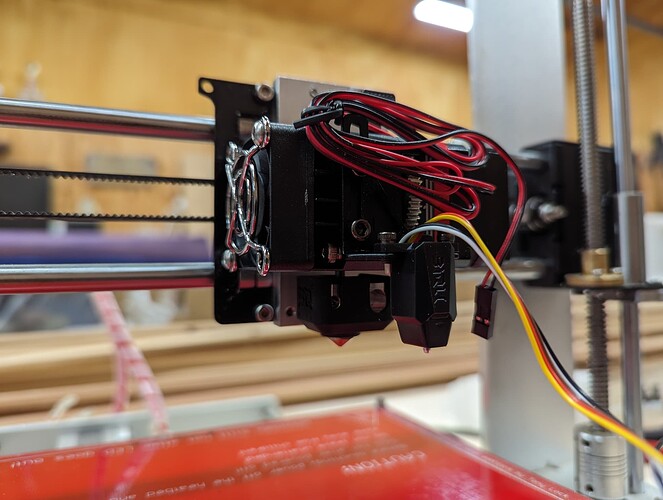

The h2 has been mounted onto the geeetech clone.

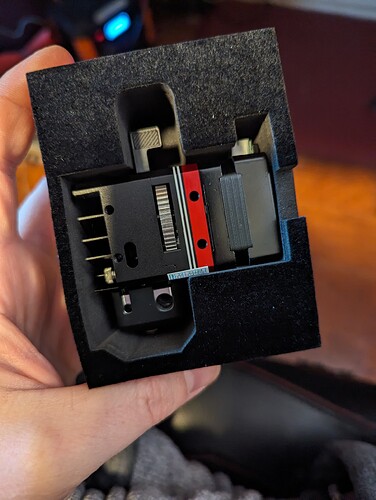

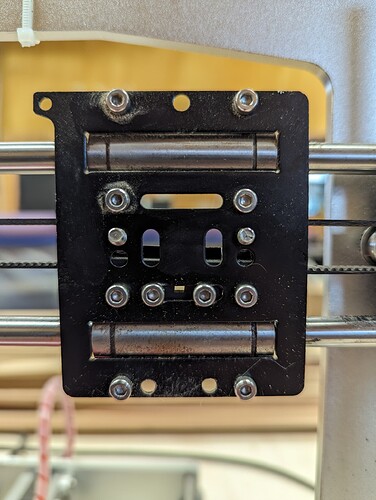

Stock mount

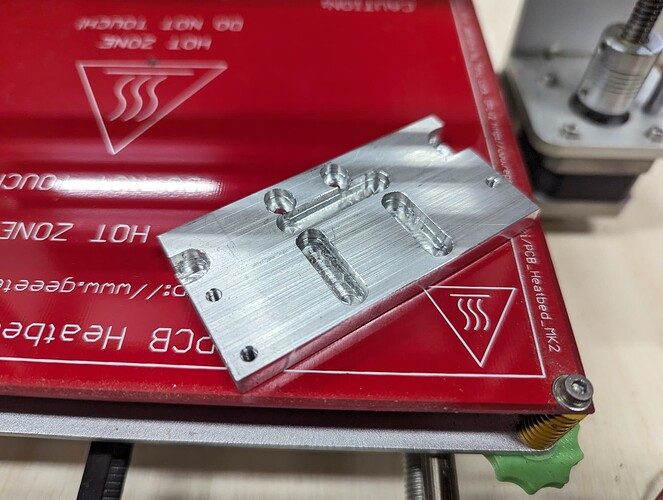

Adapter plate. I’m no blondiehacks, but it works.

H2 mounted

Print nozzle clears the bottom

I may need to rotate the nozzle 90 degrees. I hope that’s possible. I can always drill new holes in the mounting plate and lower the nozzle so the wires clear the bottom of the carriage if needed.

Voltage question for those with the Manta board…

I assume I can feed the 24v into the board for both the board and steppers. Use the 12v fan pins to power the fans. And use a 12v step-down converter to feed power in to the ‘heatbed in’ to power my 12v bed…

Does that sound correct?

We probably need some more details about your setup.

This is true.

Also true.

Here’s where the snag is. Your heatbed probabably needs considerably more current than most buck converters can supply. The manta does appear to have a separate input for the heated bed, so you could in theory keep your 12V supply and just wire that to the heatbed inputs, and then your 24V supply can run board and steppers.

But, it sounds like you want only a single power supply.

Maybe put the heated bed output from the board into ssr and gate the 12v through that… but it would still require 2 power supplies or a buck to get the 12V

Exactly.

This was going to be my question and suggestion if it has the separate power input. Honestly your best bet

hmmm as I look at my 150W laptop 19.5V power supply… got a few of those laying around.

The buck converter I bought is good for 20 amps. A 12v heat bed with a 1.2 ohm resistance should only pull 10a.

A 120W heated bed? How big is the bed (200x200mm)? If you only pull 120W and have a 20A 12V buck converter then yes, that would work. I’d make sure you have a good fan on the heat sinks of the buck converter.