Step one complete.

The h2 has been mounted onto the geeetech clone.

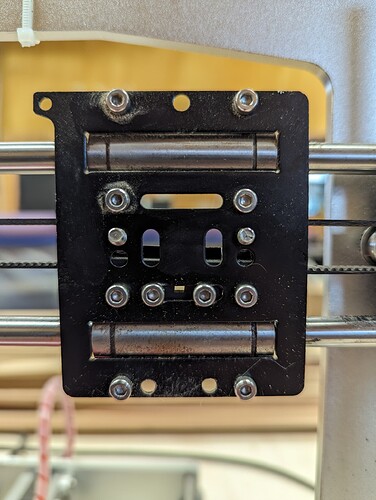

Stock mount

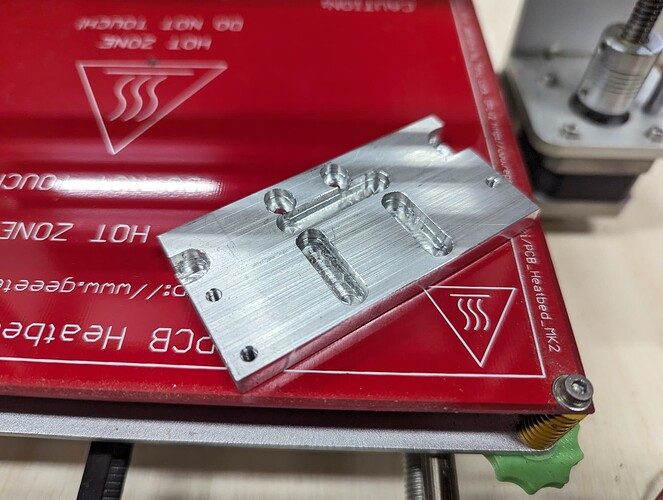

Adapter plate. I’m no blondiehacks, but it works.

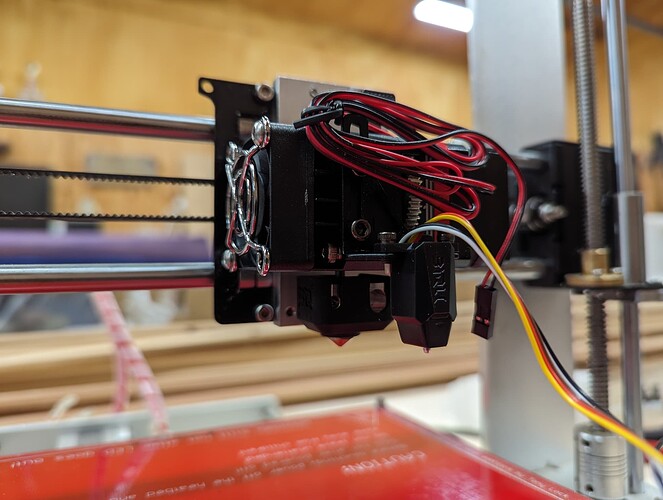

H2 mounted

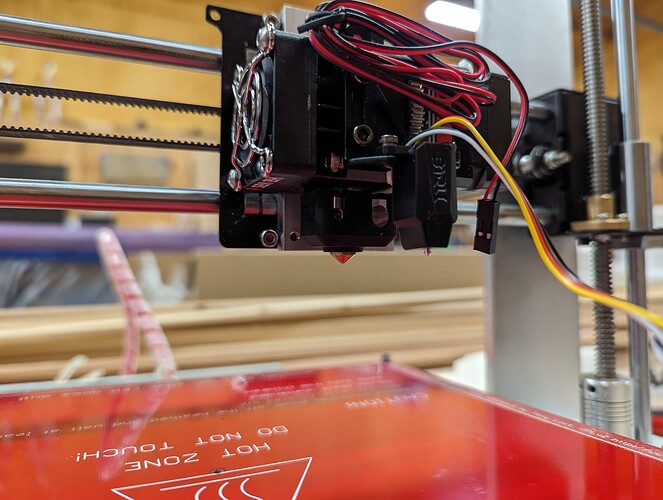

Print nozzle clears the bottom

I may need to rotate the nozzle 90 degrees. I hope that’s possible. I can always drill new holes in the mounting plate and lower the nozzle so the wires clear the bottom of the carriage if needed.