Diamond bit?

Diamond bit as in a grinder/burr?

Yes, it works great, look at the (normally) really clean cuts in plywood (for instance with the French Cleat). I only use 1 and 2 flute endmills for “real” wood and MDF.

Also keep in mind that if I switch between conventional and climb, the error is in the other direction, so the parts are not smaller but bigger. Something must be able to move.

How does the bit look?

They are fine, I tried several, also ones that haven’t been used since I took down the primo.

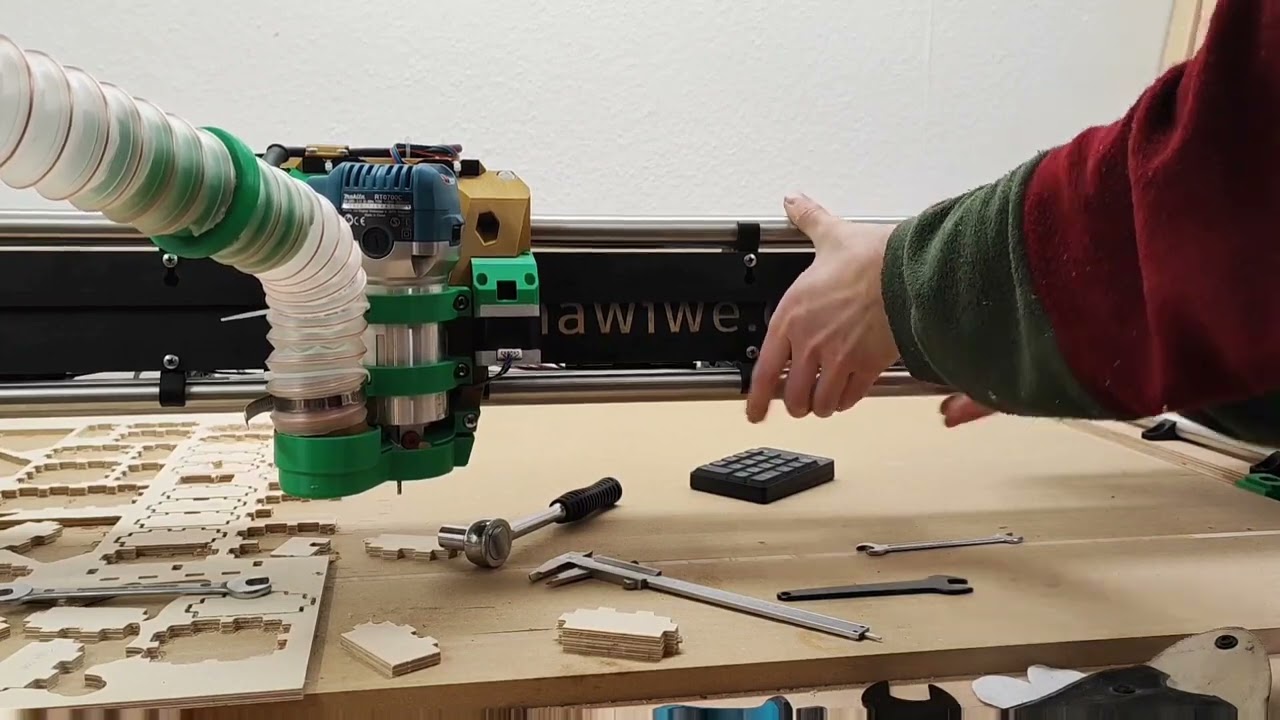

@vicious1 (and obviously everybody that cares) Should it be like that? Second half shows me puling/pushing the endmill.

No idea what deflection/twisting is acceptable for different vertical loads. Happy to help do similar tests, any suggestions on how to do test in a way that’s easy and reproducible, e.g. rig up way to load up core with weight, alternatively pull up with rope around suspended pulley with weight? Ideas from people appreciated, will try to help.

Cheers!

Just grab it and wobble. ![]() It’s not about being accurate about force at the moment but about whether this should be possible. The steppers are engaged for the test.

It’s not about being accurate about force at the moment but about whether this should be possible. The steppers are engaged for the test.

Woo… It looks right, it is right, it was the one flute…

I think I reduced the speed for the diamond endmills too much, forgot to up the RPM … will test that later.

Some flex is normal. You are much stronger than the force needed to cut. The grab and yank test is not a precise enough test to see if you have an abnormal amount of flex…

This is normal too. If you want precision parts, you need it use a finishing pass. The rough pass removed most of the material. The finishing pass has zero load (it is only removing the flex, and 0.3mm or whatever your setting is). No flex on the finishing pass, so parts come out to the desired dimension.

There are abnormal amounts of flex. And abnormal amounts of error. The biggest thing is just trying to keep the load low. A dull bit will stop any progress.

Thanks Jeff, precise as always. ![]() I wasn’t sure about the force, and you get paranoid after nearly reworking the whole LR and then having the same problem… -_-

I wasn’t sure about the force, and you get paranoid after nearly reworking the whole LR and then having the same problem… -_-

I am really relieved I found the problem being the diamond endmill (Sorotec Online-Shop - Werkzeuge) that I always used with the Primo, because Zenziwerken exclusively uses it for plywood and it always worked great.

The LR makes different sounds than the Primo whenn the RPM are not high enough, hence I did not figure that my RPM are too low and I never even thought that this could result in those problems. I am going to try this evening with max RPM and work my way down, the same I did with the Primo back in the days, since normally the finish with the diamond endmills is much nicer in plywood than “normal” endmills because it does not tear up the top layer (I say normally, because my pictures say something else… :D).

Cheers for all your help!

I don’t want to rub it in, but that endmill honestly looks very unusual! I would think sideways cutting and chip clearance is worse than on the standard single flute mills. Perhaps your Primo was so solid that the endmills different characteristics didn’t matter?

A lot of people are using them especially for ply- and balsawood, because it doesn’t tear out. I will see how it goes later with higher rpm.

Previously I had only seen these used for things like Carbon Fiber, with water. Meaning, it grinds or sands it’s way through very slowly. If you are going to use this with wood I would suggest trichodial or a large finishing pass. Slowly to decrease load.

To avoid tear out you can use a compression bit for both sides (and a full depth cut), or an upcut or down cut depending on the face you are worried about. The other thing is a roughing and two finishing passes. The key is the size of the chip evacuation route. If the chip can not get out of the way before the next cutter face you will recut chips and dramatically increase the load. I think a simplified version of that endmill is sandpaper, vs a single flute being a sharp chisel or plane.

As I said: I’ve nearly exclusively used them for the last two years, have to do some testing what the issue is with them now. ![]()

They are actually really awesome if done right.

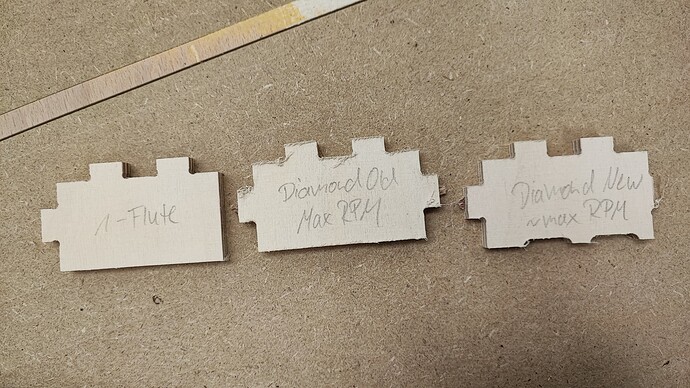

Okay, the testing has concluded for now:

From left to right:

- 1-flute, low RPM, best results in that wood, very clear cut.

- Old Diamond bit that I used before, full RPM, a lot of tearout, not really great, but not as bad as before either.

- New Diamond bit, nearly max RPM (but not completely), cleaner cuts, better fit, but not as good as the 1-flute.

The aftermath of all the tests and the tears that were shed… ![]()

What I learned is that I should maybe use a 1-flute. I never bothered to try that because the results were always good to great and it is what Zenziwerken uses, I cut stuff from him first. I am now going to order a few 1-flute. ![]()

Thanks for all the help, I learned something. And even if it wasn’t the core’s fault completely, I am glad that I reprinted it. ![]()

That is a lot of test cuts !!

Glad you have something that is working now. Was neat following along.

You’re so close to having an Idex now?

No, nope, never. That would mean software. Using the wrong one, can’t code to save my life. Interactive PDFs and other fancy stuff with LaTeX is what I can do, after that it becomes uncharted territory. ![]()

If you can do that, no wonder you can work with raw gcode… I do write software for a living, and LaTeX is something I’ve only dabbled with, for good reason. Usually because I wanted a document with the aesthetic of old Slackware manuals…