I only need to fasten a few screws for the back strut plate, drag chains for X and I need a button for the autosquare, but besides that I am done.

Running the lowrider with 8000mm/min for travel. I did try 20000 just for the lulz, but one motor was skipping steps and it ended up twisted. ![]() Nothing broken though. I also rammed into an endstop, but I was able to bend it back.

Nothing broken though. I also rammed into an endstop, but I was able to bend it back.

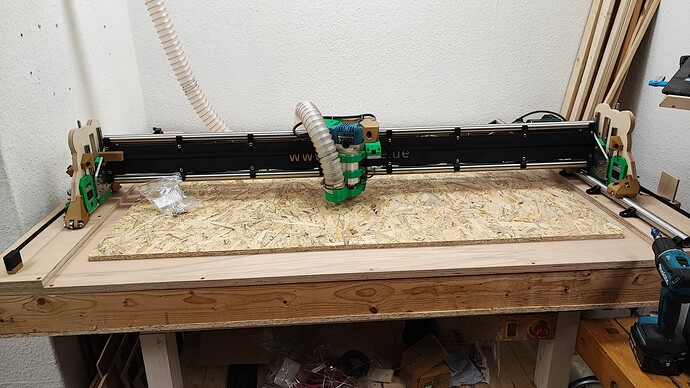

Temporary spoilboard in place for cutting the control box.