Okay, the testing has concluded for now:

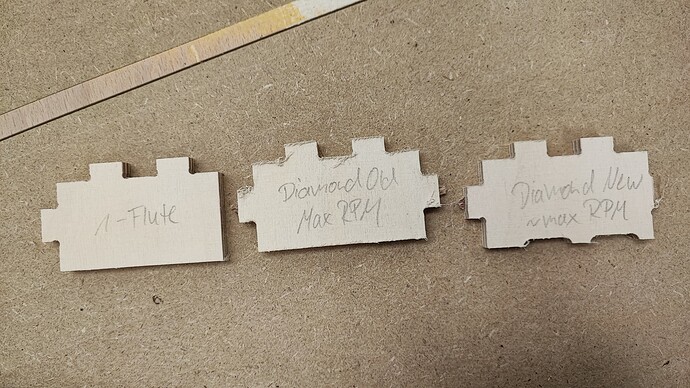

From left to right:

- 1-flute, low RPM, best results in that wood, very clear cut.

- Old Diamond bit that I used before, full RPM, a lot of tearout, not really great, but not as bad as before either.

- New Diamond bit, nearly max RPM (but not completely), cleaner cuts, better fit, but not as good as the 1-flute.

The aftermath of all the tests and the tears that were shed… ![]()

What I learned is that I should maybe use a 1-flute. I never bothered to try that because the results were always good to great and it is what Zenziwerken uses, I cut stuff from him first. I am now going to order a few 1-flute. ![]()

Thanks for all the help, I learned something. And even if it wasn’t the core’s fault completely, I am glad that I reprinted it. ![]()