Have you made a business with your CNC or 3D printing? If so, what’s it called and what do you sell mostly? Have you thought about starting a business using these wonderful machines? What would your potential business be called and what would your niche be?

I have a registered business since last year, it’s called HaWiWe, has got a website www.hawiwe.de and I am selling LowRider assembly as a service, Strut Plates as well as skateboard mounts, boxes, cutting boards (in theory).

In reality I have sold one LowRider, one pair of strut plates and one skateboard wall mount…

But my local Skateshop is now going to sell my mounts. Let’s see if there is an opportunity there. ![]()

P.S.: maybe change the title? ![]()

I think your husband has got a business as well… ![]()

She’s the boss. Not me ![]()

We are building up North Woods Custom Creations. Right now our main Item is full built V1 LR4 Machines. I am about to box up #7 tonight and have started printing #8, but it will get assembled, tested and shipped next trip home.

Other than the LR4 we do the occasional sign or other custom CNC work. So far its been a lot of fun and is funding our hobbies lol.

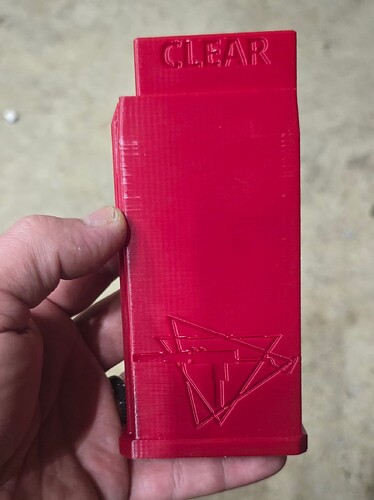

So i wouldn’t say it’s a business but more of a support to the in-laws’ business. They own a gun store and my brother in law has been shooting competitively. There is a safety requirement that at the end of each course you have to have a bright colored marker showing that the gun is safe and nothing can possibly get into the chamber. So i designed a fake magazine that goes in, blocks the barrel and locks the bolt open so that there is no question about the safety of his rifle. I added his logo to the side and a couple other little cosmetic things he asked for.

This is the prototype. The real ones will be orange abs instead of this red pla

There is a company that sells them online for $15 but the goal is to get these cheap enough that they can include them with every rifle they sell.

that’s neat

any chance you can modify it so it prints laying horizontally? Kinda like if you just rotated the image 90 to the right. Might lessen the chance of it breaking at a layer line inside the gun.

I’m not sure the make and model here, but on the side facing us, that bottom lip could be removed allowing 90% of it to print on the bed, with supports only for the tongue.

I’m guessing that the other side has the catch, or am I flipped around? I was thinking that we’re looking at the right hand side from the operator’s perspective, but it looks like your thumb might be on the front?

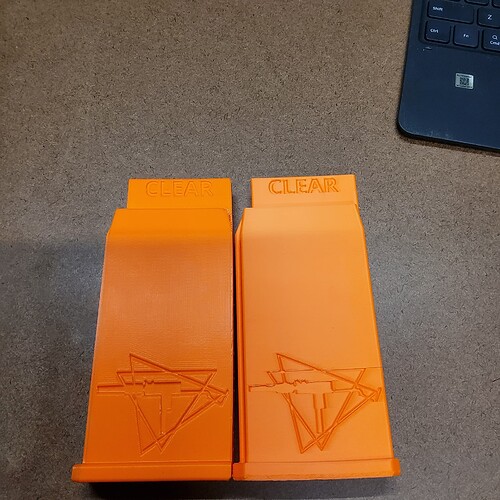

Had the same idea. it’s definitely doable except that bottom is modeled after a common magazine maker to feel the same in the hand when switching. It’s a split second difference but this competitions are timed every little bit counts. I actually wanted to lay it down for better layer orientation. There is little no force under normal conditions, but if the user releases the bolt it will slam into the top part that says clear. It is feasible that because the five of the bolt is parallel to the layer lines that it could break free and lodge in the barrel. I tested over and over and over for coke to an hour. After hundreds of times the only way i could tell was an oil mark where it made contract. That isn’t supposed to happen, but with how far done of these guys are going it COULD happen.

I’m just imagining someone hitting the mag sideways while moving the gun around and snapping it off at the mag well. Might not happen, but would suck in a competition.

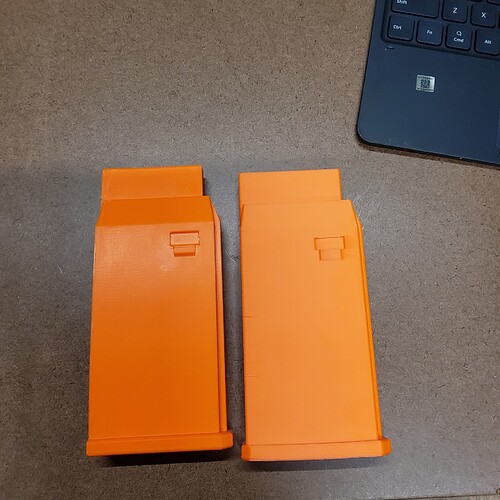

thanks to cracking and and a few other artifact issues that I couldnt find, I had to lay it flat to see if it got better. It did. Redesigned the chamfers to just make it the way. The left is the laying down and the right was printed standing up.

I have never used this eSun ABS HS before and its not bad but it definitely does not print like other ABS I have used previously. I had to adjust temps, flow, cooling, overhangs, speeds (down not up)… basically everything. I’m sure if I spent the time and energy I could tune this stuff to print as well as the other ABS, but at this point I am almost done with the spool and will go back to Sunlu ABS or Polymaker. But really, this is the only spot I am not happy with and I already went into the CAD to make it flat with the rest of that face.

ok no more hijacking this thread I promise.

When I retired, which was quite some time ago, I made a conscious decision to never do anything for money (unless I could no longer afford to do so). This is because I strongly feel that if one is doing stuff for money, one is at work and we were determined that money was never going to be the driving force in decisions we made in our retirement. Human nature says that no matter how much one has, one always wants a little bit more, and it’s so easy to forget what the goal was.

Therefore, my 3d print models are and will always be free downloads. Most things I make are solving problems for friends or making repairs for strangers.

I accidentally became a member of our local Repair Cafe, so anything with a broken part usually comes my way for a bit of remanufacture. Tomorrow, it’s a sewing machine with a broken part, that was donated to a charity shop. That shop in turn donated it to a sewing group for young people. If I succeed in manufacturing the new bit, a young person who can not afford one will receive a sewing machine to get him/her started. I’ll post pics here if it all works out.

This is something I couldnt agree with more if I tried. It doesnt start out like that, but it gets that way.

A few years back I made an outdoor bench for my wife. She posted it on FB to brag and within 48 hours I had orders for almost 50 of the silly thing. It went from a project that I enjoyed doing for someone I love, to a crunch time must get it done stress generator instantly. Even these magazine blocks I’ve posted have become undo stress. It was supposed to be just making a few simple parts for my brother in law to pass out to people at these competitions. But that turned into pricing (for them) and snowballed into something that has taken me 5 or 6 iterations and 4 or 5 trips to their shop to test and get “customer aproval.” The only way I can recoup the time engery and money spent on this so far would be to either charge them for it, or sell them to another local shop. Where I am now is in contrast to the line I quoted and the way my wife and I want our life to be right now.

I love this!!! There is a local maker space starting out and I have been tempted to go talk to the powers that be about helpng them. But it looks like they are throwing top dollar at it and I have no business trying to step in on that. Lets face it, half the reason I have a LowRider is because I cant afford a store bought machine to do the same thing. Keep us posted on the update of your project. I love the whole idea behind what your doing and the cause behind that cafe.

That’s quite a nugget of wisdom. I’m still a ways out but have been planning for “early” retirement since I’m not sure I can manage to work another 25 years to a “normal” retirement age. But I don’t want to retire too early if that means I still have to work, especially if that means killing the fun of my hobbies.

Either way, making things without being pressured by deadlines/paperwork/BS is high on my list of things to do in retirement and right now.

My wife and I retired last year. It is pretty great.

This is good advice. Of course, I love helping people and teaching them things. A neighbor wants to do a (very altruistic) startup and has asked me a few times for printed parts or software advice or CNC parts. I have helped him find service that I think would work out and printed a few prototypes. I did some CAD on one I didn’t think would work as is. But he keeps wanting to get me on the payroll for software and I just have no interest. He would either pay me too little and I should go back to my professional career, or he would pay me more than the business could afford and I would feel too much pressure to succeed. I just want to ride my bike.

That should be printed on your new work uniform. You could start a business selling them, ![]()

![]()

How? You are, like, 46… ![]()

dont hate! Im 43 and have been retired since 2020

It depends. Would you want to Fat FIRE (save like crazy with enough to do whatever you want), Lean FIRE (live a modest lifestyle), or Barista FIRE (“retire” to a part time job you enjoy)? “Financial Independence Retire Early” is a whole rabbit hole that my wife thankfully dragged me into.

Basically, good paying jobs help, living well below your means, investing heavily starting as early in your career as possible. Paying off debt. It depends what retirement means to you. My wife wants to “retire” to a part time, non stressful job. I don’t want to have a job at all. My risk tolerance is much lower than hers. Heathcare when retiring early is a challenge, especially in the US. A lot of tax advantaged investments require some strategy to access before 59 1/2 so separate brokerage accounts are helpful too. I expect to retire between 45 and 50 but we’ll see how it plays out.

I think I was 47 or 48 when Shaneh let me retire.

That’s exactly where we are, and have been for almost two decades.

With time running out, we are a little more relaxed about our diminishing capital, so expenditure on things like unnecessary CNC machines than we might have been a decade ago. ![]()

Yep! We borrowed against our house to make up the shortfall in our income, calculating that the value of the house was going up at a greater rate than our debt, so we could sell it, pay out our loans and “build” a more suitable place with the balance!

The only thing we didn’t factor in was a change in Government plans which required the demolition of our house to give way to a new bridge! ![]()