These little 28BYJ-48 steppers are geared way down and you need drive them with a lot of steps to move any distance at all. Put in a pretty large steps/mm number (1000?) and try moving a convenient distance (10mm)… hopefully it perceptibly moves. If it does, measure the actual vs commanded movement and compute the scale factor (commanded/actual) to multiply the current steps/mm by…

They actually can be driven with our little stepstick drivers. You just need to set in a very small Vref that keeps the current low enough to keep the generated heat manageable… they’re drawing current even when holding position. Unfortunately I don’t remember the numbers I used way back when…

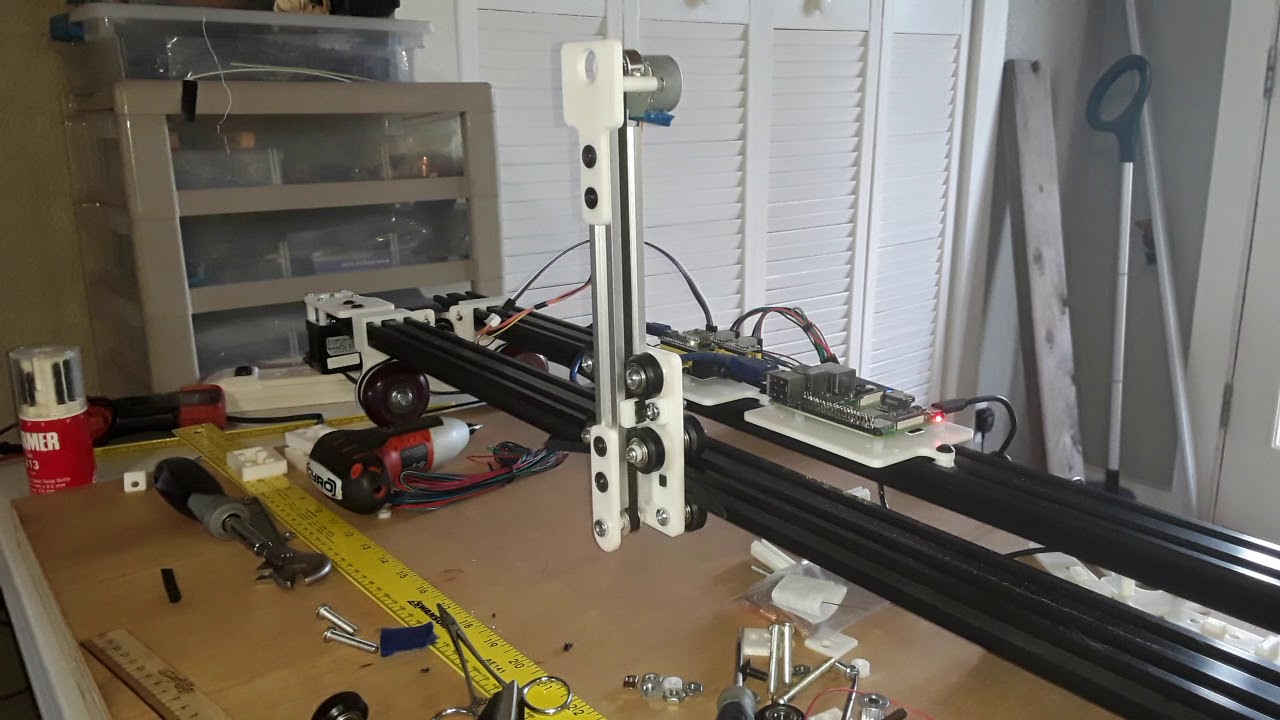

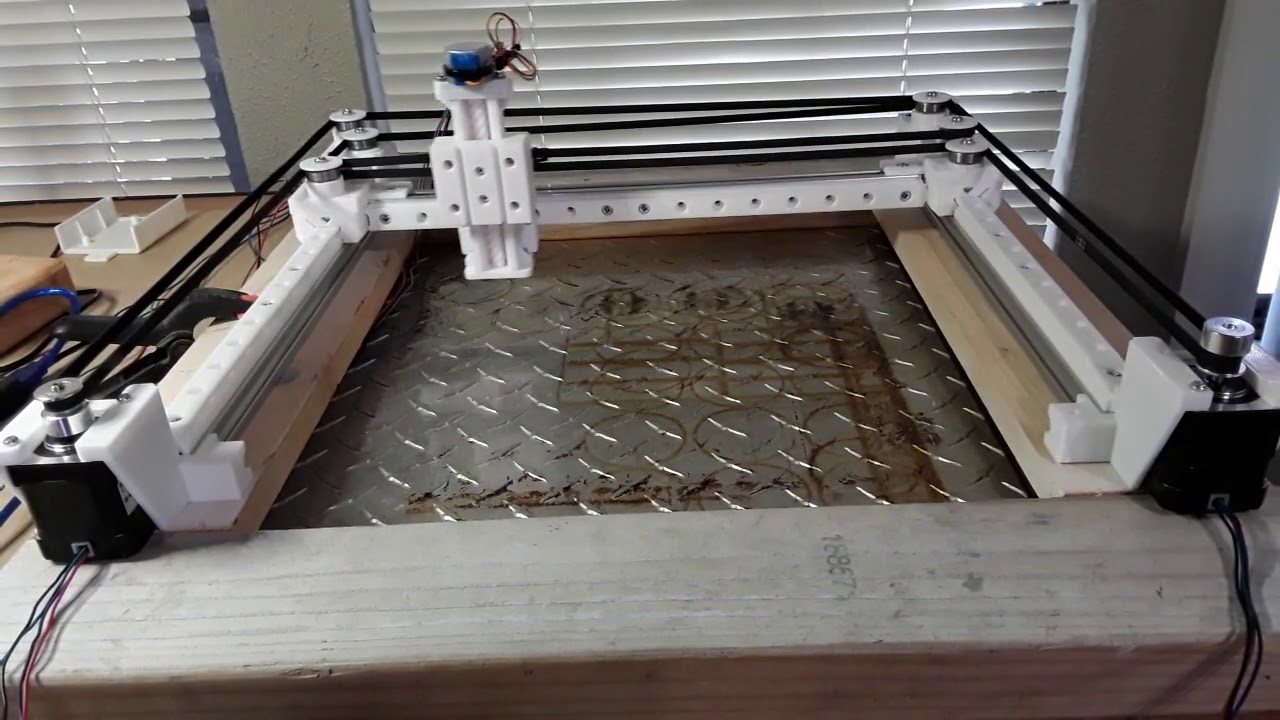

Eventually the Z-axis morphed to this…

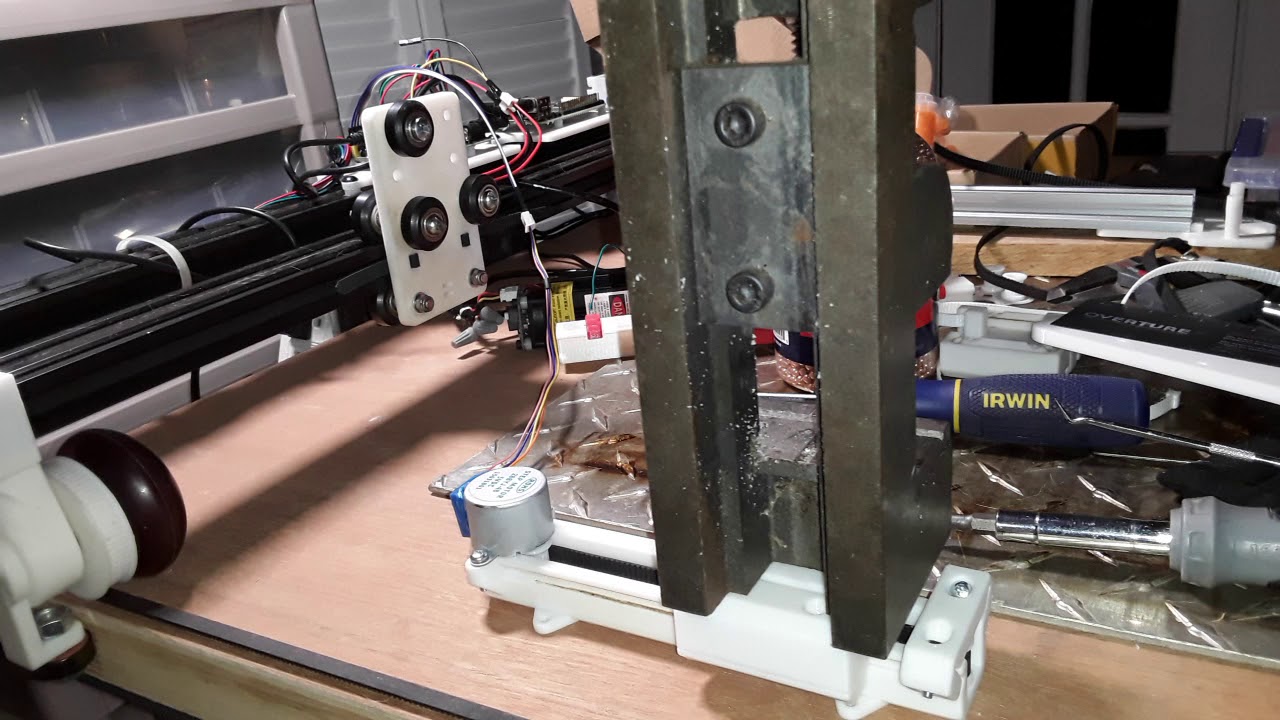

and then ultimately became beltless in favor of a printed leadscrew.

Here’s the portion of my long thread where I played with this little motor. IIRC I think I ditched these belt-driven Z-axis designs because because I kept losing my focus distance every time I powered down and the motor ran hotter than a firecracker… ![]()

– David