I wasn’t expecting that.

What the heck even is that?

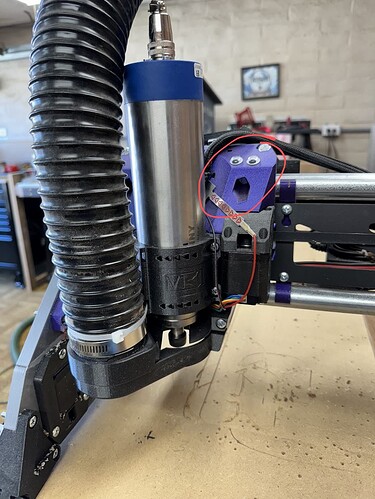

It looks like the collet was dragging around on the work piece without a cutter.

So my forward/reverse is flipped. Tomorrow I will change 2 wires on my VFD to flip it.

It’s a little dumb because the instructions say to wire 1,2,3 to UVW but I guess that is reverse today.

I could just have the button logic reverse from the instructions too.

I did that once ![]() I didn’t realise that I had pressed the for/rev button on the VFD controller.

I didn’t realise that I had pressed the for/rev button on the VFD controller.

No, friction stir welding is for metal, not wood. duh! ![]()

I think the Makita has much more power than this spindle. You can hear the spindle bog down. This is the same exact gcode.

Makita

Spindle

This is the big 1" bowl bit I use all the time. It is a little dull, but it was equally dull for these tests. I’m cutting extremely hard maple in the video.

So far, I don’t really think this is an upgrade. Maybe a lateral change at best.

I am running a 30 minute job cutting hard maple and the spindle is struggling hard. I kind of want to switch back to the Makita to see if it struggles on this exact piece of wood too.

edit: I actually stalled it completely once so far

Sounds like some settings are incorrect in your vfd. Or there is something wrong in the spindle.

I have no idea what I would change. It seems fine running a 1/8" bit. I have no complaints. My bigger bit is too much for it though.

The whole machine is pretty warm / hot. All my steppers are almost untouchable. One of the z endstops stopped working until I opened the control box to let it cool down a bit

Oh, they are only ~109F

bahahahaha

That’s me evaluating this spindle

Just sounds like you have more RPM on the Makita, which I think is typical. Such a big bit the extra RPM gives more rotational inertia to power through. I dont necessarily think it is an indictment of the spindle, but more of a “right tool for the job” thing. There is a reason routers are routers. If you ONLY plan on doing hardwood and big bits maybe the Makita IS the better choice despite the slightly higher power of the spindle. Remember power doesn’t always equal speed.

I know for me I want the ability to do wood and metal, plastics, etc…so the versatility of the spindle is attractive.

I don’t have a tac, but based on the documentation they should be pretty close to the same speed in the video.

Just wanted to close this out. Here were my original thoughts:

don’t cost as much as they used to and are more quiet, speed controlled, and potential help with dust collection.

Don’t cost as much as they used to.

I was about ~$300 in after the spindle, VFD, and cable. Price was right, but I don’t think a 1.5kw is equilvant to a Makita. I think you would need at least a 2.2k or maybe a stronger 1.5kw? I was reading early on that the numbers aren’t always right with Chinese spindles. I would assume this one is though, becuase it is what PwnCNC sells.

are more quiet

Sure under no load. Ryan made the point early on that the cutting noise is loud, and so is the vacumn. Running a smaller 1/8" bit was a little quieter, but bowl bits make the same amount of noise.

speed controlled

It is nice to be able to choose the speed more granularily. You need extra parts to connect to SKR Pro or Jackpot.

potential help with dust collection.

Not really anything noticable. Maybe for the 1/8" profiling, but not for bowl bits.

–

I don’t really want to have to warm up my spindle before using it either. I probably don’t have to in my climate, but just another annoying thing to think of.

I will say that I am still happy I gave this a try. I think it was a fun experiment and I learned a bunch. Now I don’t have to wonder all the time.

I returned it.

I think the makita is about 700W on the box. I have no idea how they rate them.

Chris from Scienci published a chart and a video about this and it seems under 20k RPM the brushed motors are considerably stronger.

Thank you for sharing your experiment with us, thanks for saving me the process!

Depending on the bit and the material yes very much so. But after having used purely spindles for 2 years now, and going back to a trim router on the LR4 beta, there is still a very noticeable difference. I also don’t have the vacuum noise, my dust collection is in a lean-to outside of my garage so I can barely hear it running when nothing is on.

I did the original run in on mine and never did a warm up again, even after it sitting dormant while I’m off shore at work for weeks at a time.

I hate that you didn’t have a better experience with it. I have had a different experience with mine for sure. Nothing is perfect and it never will be. But seems there must be some differences in how some of these are made. So far I have only ever stalled mine one time, and that was for sure a CAM error on my part. 1 1/4" surfacing bit, with dull inserts, cutting more than 10mm DOC. It was stupid for me to ever let it keep going but I just wanted to see what it could actually take lol. And I was super impressed!

I think people really underestimate just how much power it takes to spin a 1"+ bit over 20k RPM and how much a traditional router is relying on inertia as much as raw power to cut with such a large cutter.

I think most of the 1.5kW spindles come with ER11 collets for a reason: they are only meant to take bits up to 1/4". I held out for a 1.5kW with an ER16 so I could go up to 3/8" but I know my mileage my vary with that…and I doubt the designers had bits with a cutting edge much bigger than that in mind.

I think these bits are even pushing it for the trim routers we use, which often are colleted to a max of 1/4". Usually such large bits are meant for bigger routers with 3/8" or 1/2" shanks.

I have a 1" surfacing but with a 1/4" shank, but frankly I’ve only used it once…if that shank gives up at full power thats ALOT of steel and carbide to fly around at 30k rpm…

I’m not trying to argue that the OP was wrong in his assessment…I just think this a “right tool for the job” type situation. If a wood router gives him better success with what hes trying to do, he should absolutely do it. But spindles have their place.