Since my last Mancala project, I basically doubled my speeds. I don’t want to baby my machine anymore, and if I break my Makita, I get to buy a Kobalt router.

Here are my settings with the Whiteside 1406 round nose bit. Watch and hear it cut here - https://www.youtube.com/watch?v=vNCky97kfUA

2.75mm DOC

60* plunge angle

30mm/s feedrate

6mm/s plunge

30% stepover

2 Makita speed ~12k RPM

So my chip load should be

Chip Load = Feed Rate (inches per minute) / (RPM x number of flutes)

.0029 = 70 / (12000 x 2)

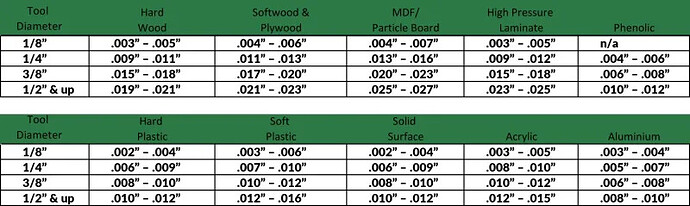

Then I look at this chip load chart - there are many, but they all have the same numbers.

To get ~.019 (hardwood) doesn’t seem realistic on my machine. Since my spindle only goes to 10k, my denominator has to be 20k.

So

.019 = x / 20,000

x = 380 ipm

So I would have to run at ~160mm/s

The reason I choose to run a little higher (dial setting 2) at ~12k RPM, is because when I hit the purple heart (not shown in video), it sounded like the router was slowing down. I am assuming this is why people buy more powerful spindles.

So what’s your thought? Am I on the right track?