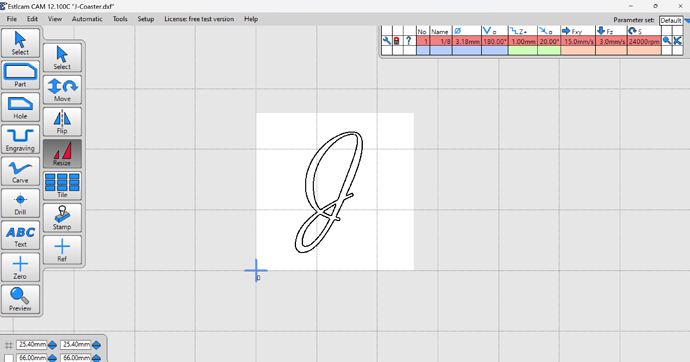

Just playing around with EstlCAM. Plan on engraving letters into small wooden coasters. Since they are round live edge wood, the size varies on each piece. Does EstleCAM have the functionality of centering the white workspace so zero is in the middle? That way I can just zero my MPCNC in the center of the live edge wood and start the cut.

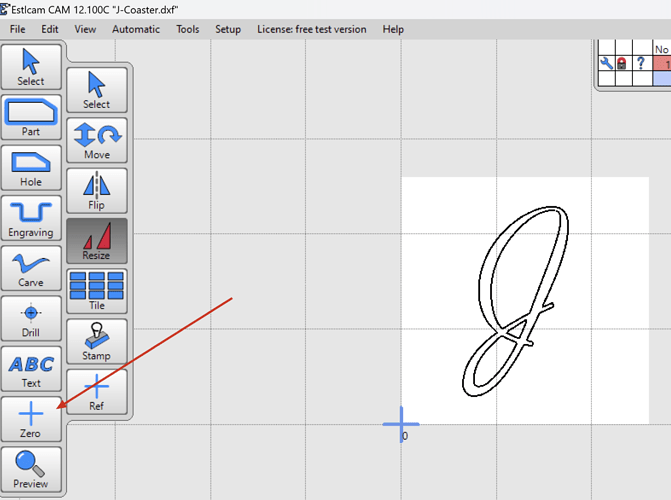

I believe this button will give you what you are looking for. If you click that it will give you a couple options, but one will allow you to pick a point to snap 0,0 to.

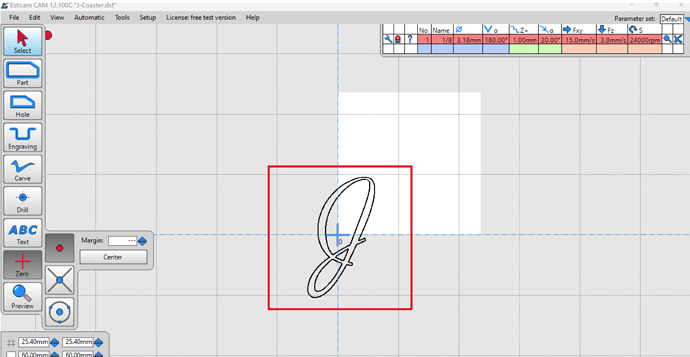

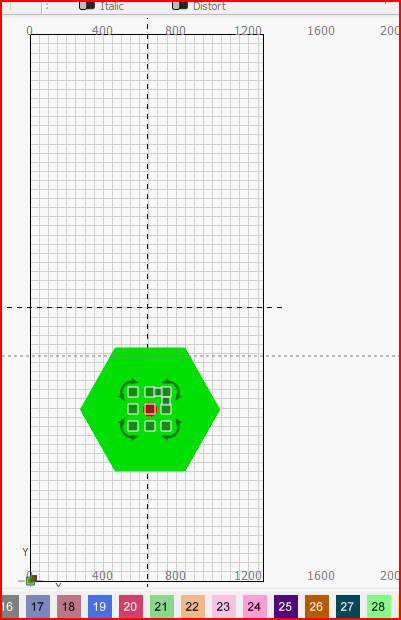

Not quite. I found that option, but I am really looking for is to get the white “workspace” into where the red rectangle is while keeping the zero in the center. I tried typing negative number down by the workspace size option but that doesnt seem to work.

I may be wrong (it has happened before) but the white space is just a guide for you to see how the work fits on a particular size of material, and is always going to start at 0,0 in the bottom left of the rectangle. When you center the project manually, you are telling the gcode to use that point as the gcode origin, (which I’m guessing is what you want to do in real life), but that won’t necessarily move the representation of the material (the white rectangle) in EstlCam.

To test this out, create the gcode for the design as you are showing it in your last screen capture,. Set your bit to be 0,0 at the point where you want the center of the cut to be, and run an air cut.

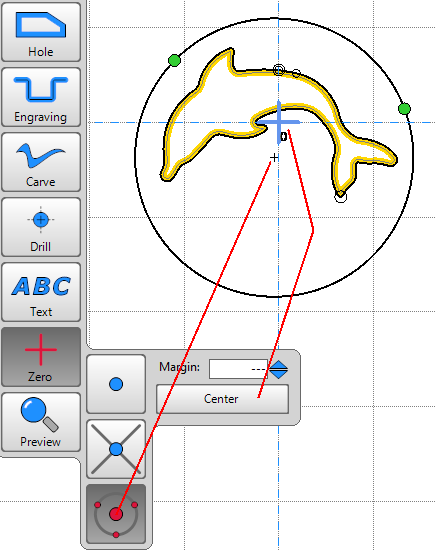

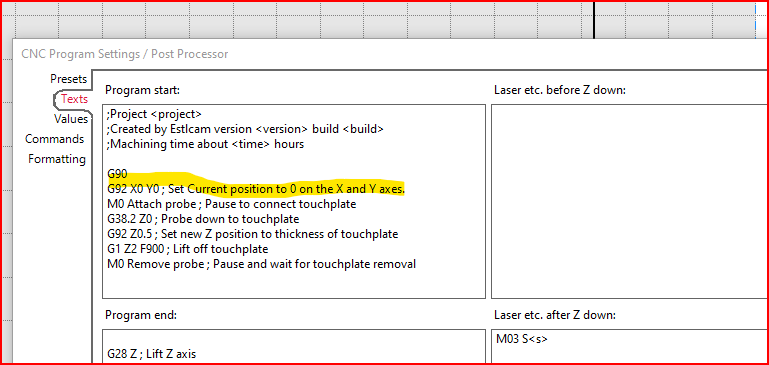

Set your Workspace to zero, set your paths and then click the Zero tool Center button. The origin will now be at the at the center of the set paths (image). If that’s not what you want, the drawing needs to include a shape that the Zero tools can work on, e.g. a circle, regular polygon or rectangle for the three point center tool (the 3rd click on the circle will move the origin to the center of the circle/workspace).

As @Bartman already said, it’s just a visual guide. Obviously you can’t put the coaster in the lower left corner of your CNC if you set zero to the middle of the workpiece, because it’s going into the negatives, but somewhere in the middle of your physical space. ![]()

setting to the center of the material is useful if the material has properties that make knowing hte center useful.

Say I’m making a set of coasters and the material I have is already circular with a center mark. Setting a workspace with that as the origin would make centering the material easier. Or say the material is crosscut wood with tree rings, and I want to center the part on the center of the tree rings. Or say I’m engraving text along an arc onto an existing piece, and I need to match the arc that the text is on to an arc on the actual object. There are many reasons why I might not want a front left origin to my machining program.

It probably doesn’t matter if I’m putting a plastic sheet down, and in fact front left makes a lot more sense then, as I can minimize waste by putting stuff into a corner. Keep in mind though that the machine often goes into negative space when using the front left origin. If you machine a simple square, for example, the router bit will trace around that square, and the machine must go at least 1/2 the endmill width into negative coordinates in order to produce the square. For this reason, you cannot usually use the machine origin as the work origin. (Exception, Marlin allows you to define endstop positions with negative offsets, such that moving into negative coordinates is possible. People use this feature for printers where different size and shape print beds can then use the same gcode because the coordinate origin is the center of the print bed.

It really isn’t a “workspace” in the gcode sense of the word. It is really just a visual aid for the 99% of people who use XMin, YMin as their origin.

Hello,

yes, the white workspace rectangle is just a visual aid and only makes sense for the default left / front origin.

For any other choice of workpiece zero it should be turned off or ignored.

I don’t want to add more options to this function - it would make things significantly more

confusing. The computer can’t know for certain what you’re actually planning to do e.g. if you want to center the design on the workpiece - or put the design at the corner or at an arbitrary distance to it. It would at least require a drop down list with more default choices or 2 XY offset fields to accomodate this.

Christian