While I’m showing off some tools, Let’s try something new… ![]()

I’m trying to optimize the stock I need for all those pieces

My LR3 has a work area of =~ 820x1800, and I need to be able to carry the panels in my car (ideally inside the car, or on the roof) over 50km

Normally, I would look toroughly at the sizes, grab a pencil and paper, and think hard about this…

But now we have AI ![]()

I want to optimize the CNC cutting of wooden pieces in 2500x1250mm panels.

The dimensions of the pieces to be cut are as follows:

- 782x578

- 398x728

- 318x728

- 398x578

- 316x368

- 206x190

- 398x578

- 398x578

- 398x578

- 398x578

- 398x578

- 368x578

- 325x618

- 618x391

My machine has a maximum cutting area of 800x1500

How many panels do I need?

How do I cut them to make them easier to transport (with a minimum number of cuts per panel) ?

Here’s the response I got:

To optimize the CNC cutting of your wooden parts in 2500x1250 mm panels, while respecting your machine’s maximum cutting area of 800x1500 mm, here’s a structured approach:

1. Constraints to Respect

Panel size: 2500x1250 mm.

Maximum cutting area: 800x1500 mm.

Goal: Minimize the number of panels used and the number of cuts per panel to facilitate transport.

2. Parts Analysis

You have 13 parts with the following dimensions (in mm):

782x578 (1x)

398x728 (1x)

318x728 (1x)

398x578 (5x)

316x368 (1x)

206x190 (1x)

368x578 (1x)

325x618 (1x)

618x391 (1x)

3. Cutting Strategy

Since your machine can only cut a maximum area of 800x1500 mm at a time, each 2500x1250 mm panel must be divided into smaller sections that fit within this limit.

Step 1: Virtual Panel Division

A 2500x1250 mm panel can be divided into:

- 3 sections of 800x1250 mm (since 2500/800 ≈ 3.125).

Step 2: Optimizing Layout

Group parts by size to minimize waste.

Example Layout for One Panel (2500x1250 mm):

Section 1 (800x1250 mm):

2x (398x578)

1x (398x728)

1x (318x728)

1x (316x368)

Remaining space: Can be used for other parts or will be waste.

Section 2 (800x1250 mm):

2x (398x578)

1x (368x578)

1x (325x618)

Remaining space: Can be used for other parts or will be waste.

Section 3 (900x1250 mm, since 2500 - 2x800 = 900):

1x (782x578)

1x (618x391)

1x (206x190)

Remaining space: Can be used for other parts or will be waste.

Estimated Result:

Panel 1:

Section 1: 2x (398x578), 1x (398x728), 1x (318x728), 1x (316x368)

Section 2: 2x (398x578), 1x (368x578), 1x (325x618)

Section 3: 1x (782x578), 1x (618x391), 1x (206x190)

Panel 2:

Section 1: 1x (398x578) (only one left after Panel 1)

Remaining space: Can be used for other parts if needed.

4. Number of Panels Needed

With this approach, 2 panels should be sufficient to cut all the parts, with efficient space usage.

5. Simplified Visualization

Here’s an example layout for Panel 1 (adjust as needed):

Section

Parts (LxH)

Remaining Space (LxH)

Section 1

2x(398x578), 1x(398x728), 1x(318x728), 1x(316x368)

Minimal waste

Section 2

2x(398x578), 1x(368x578), 1x(325x618)

Minimal waste

Section 3

1x(782x578), 1x(618x391), 1x(206x190)

Minimal waste

6. Transport Recommendations

Group parts by size for easier handling.

Cut panels into 3 sections (800x1250 mm) to fit the machine’s limit.

Use spacers or separators to prevent movement during transport.

7. Verification and Adjustment

For precise optimization, use nesting software (such as CutList Optimizer, DeepNest, or OptiCut). These tools automatically visualize the layout and minimize waste.

How cool is that? ![]()

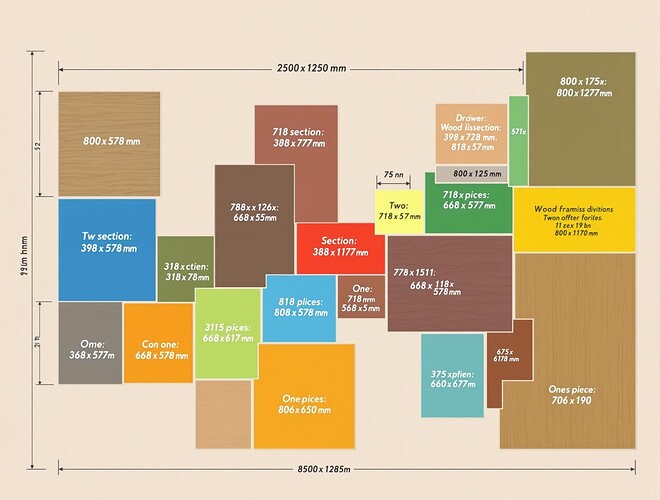

It even generated a visual representation when I kindly asked… although it doesn’t make any sense!!! ![]()

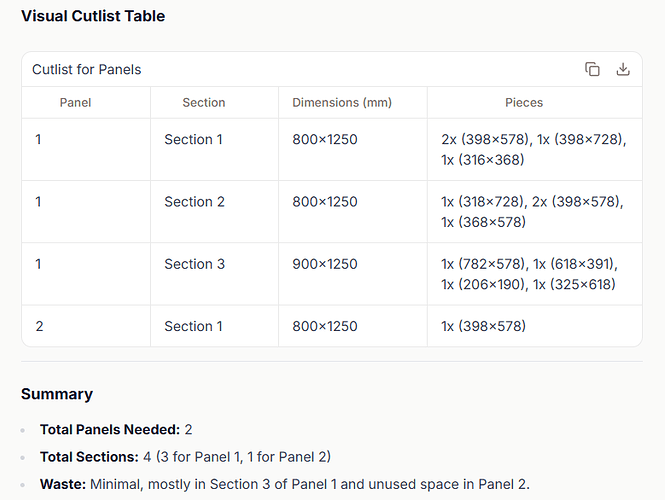

I managed to make it output a simplified cutlist though, and it doesn’t seem too bad

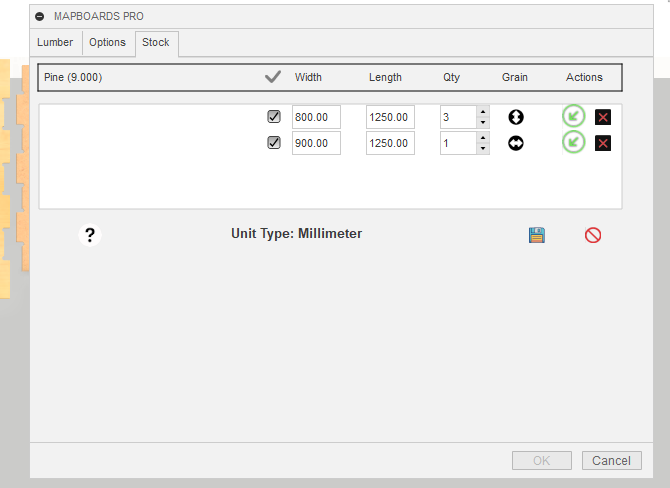

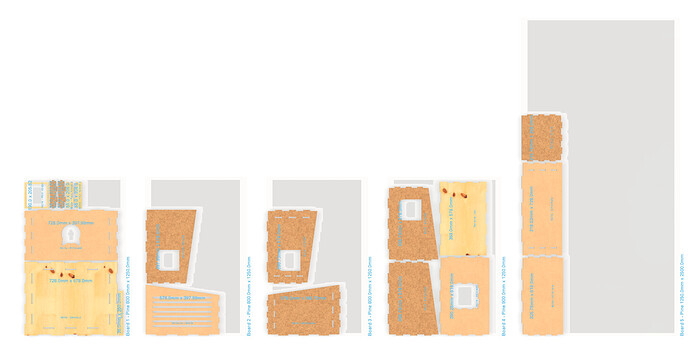

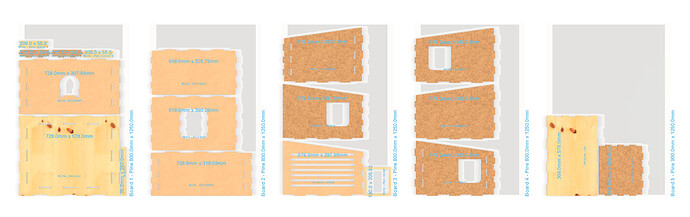

OK, let’s plug that into MapsBoard Pro

Mmhhh not quite, but we’re almost getting there….

Manually adding a 800x1250 section solves the problem and we still have some left…

Now I only need to find a way to cut those sheets on the shop’s parking lot ![]()

Hint: I made a small purchase but shhhh… don’t tell my wife ![]()