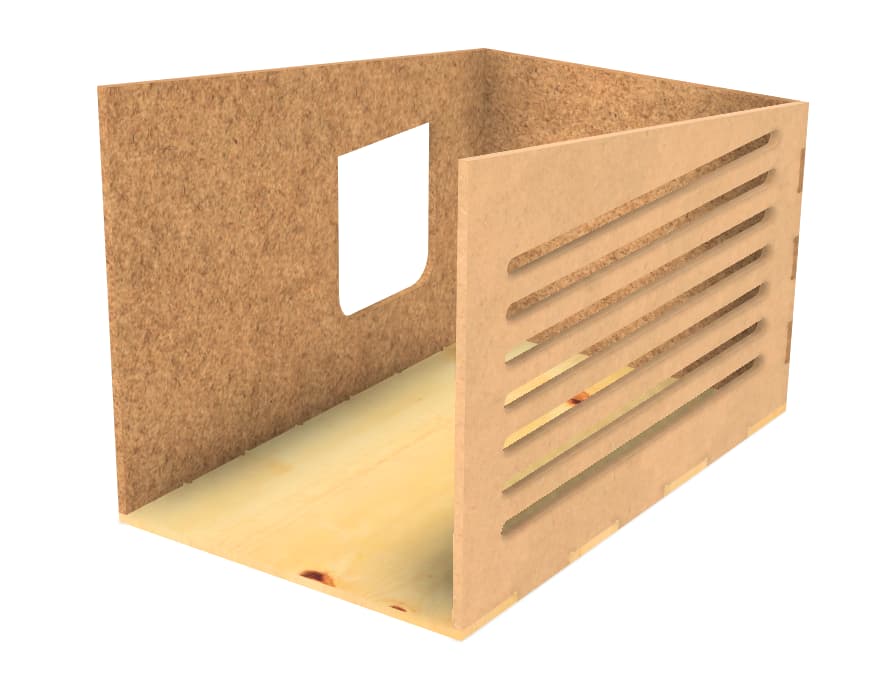

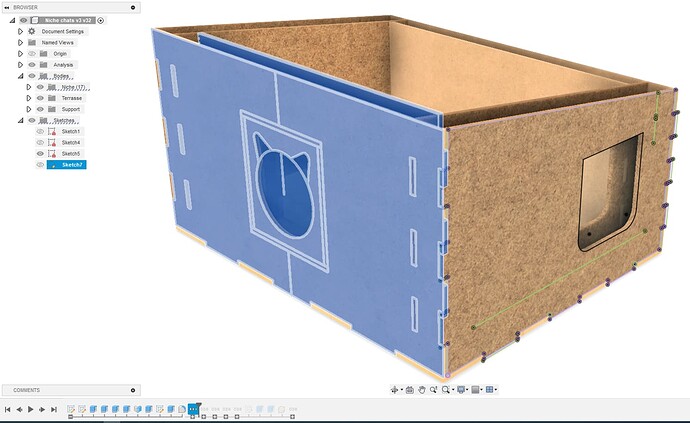

I’m in the process of designing and building a small hut/kennel for my two cats

They live outside and need a warm place to rest, so I’m planning on a fairly large well-insulated house

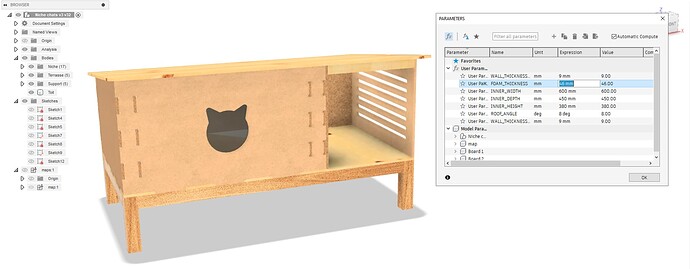

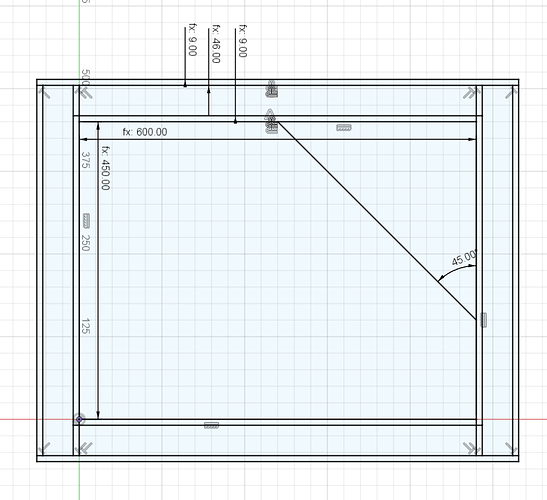

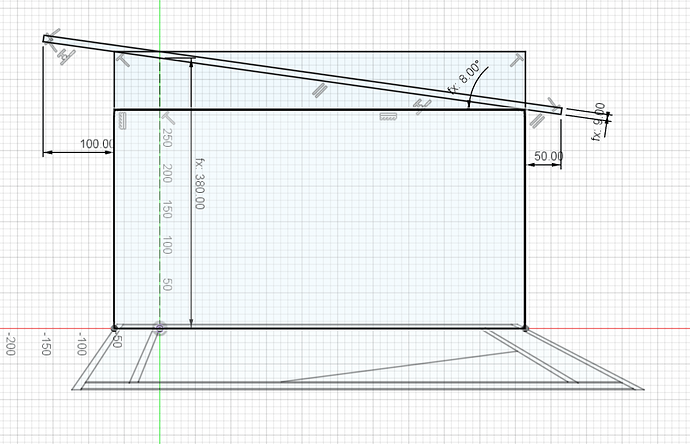

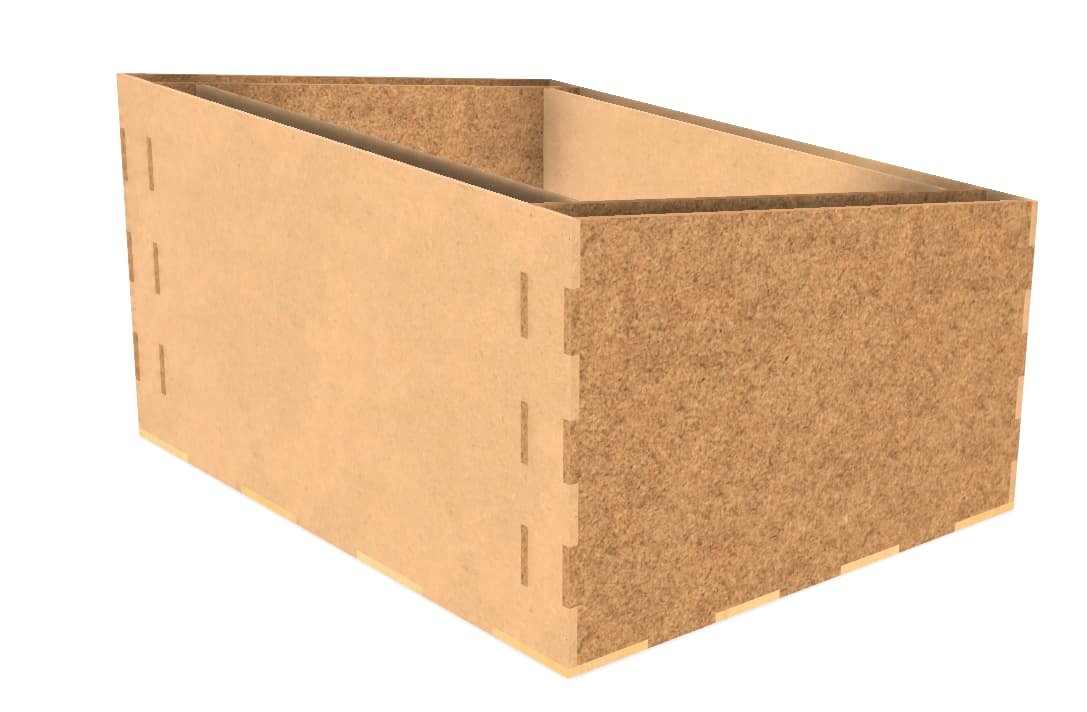

Design

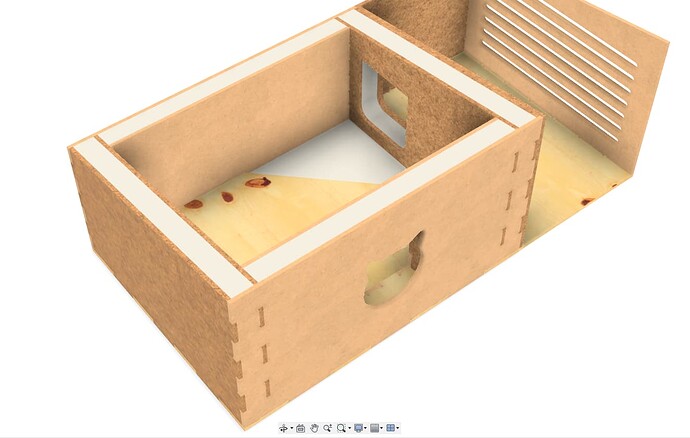

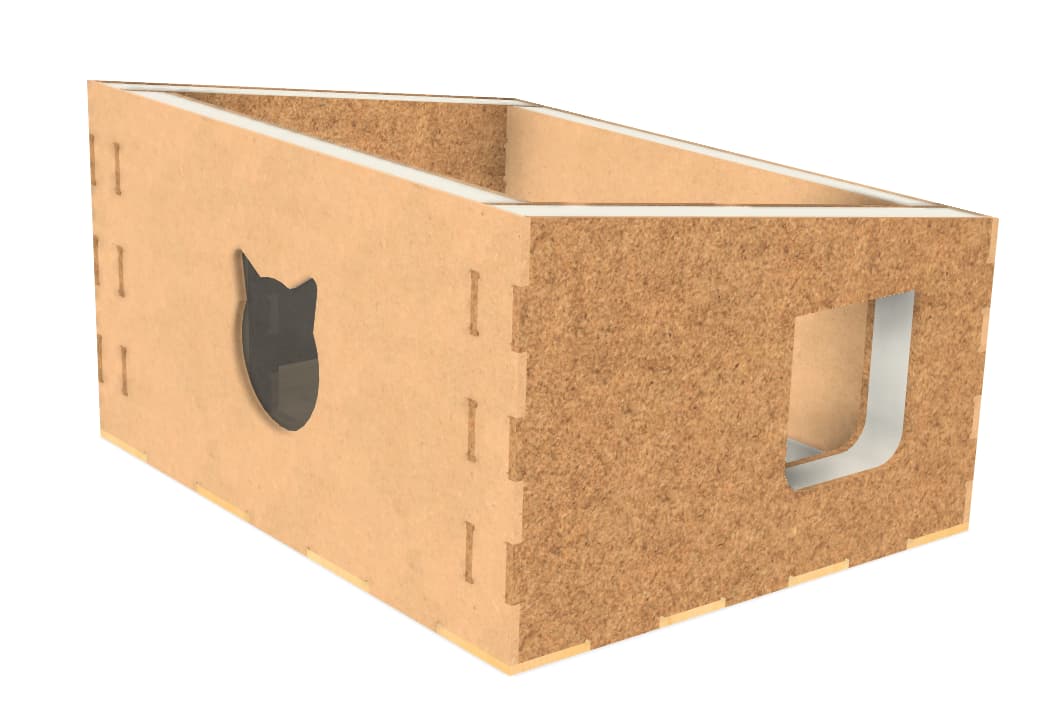

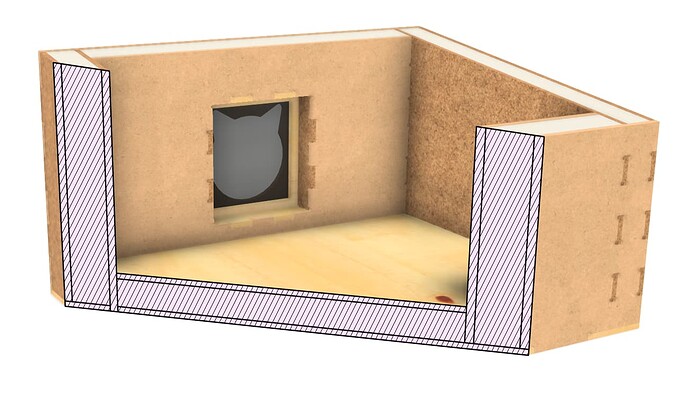

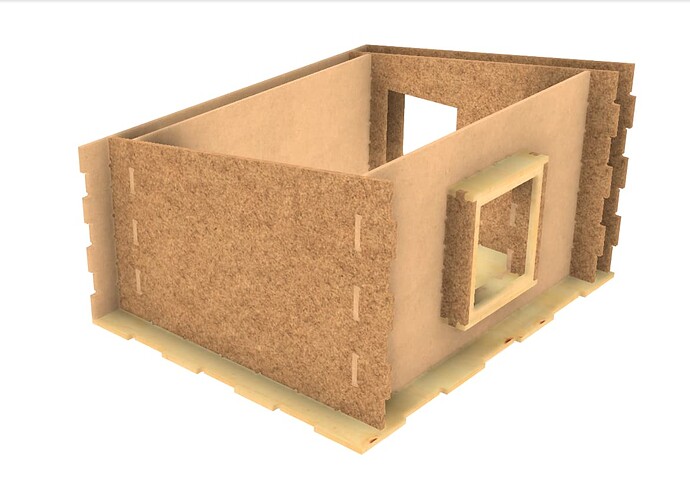

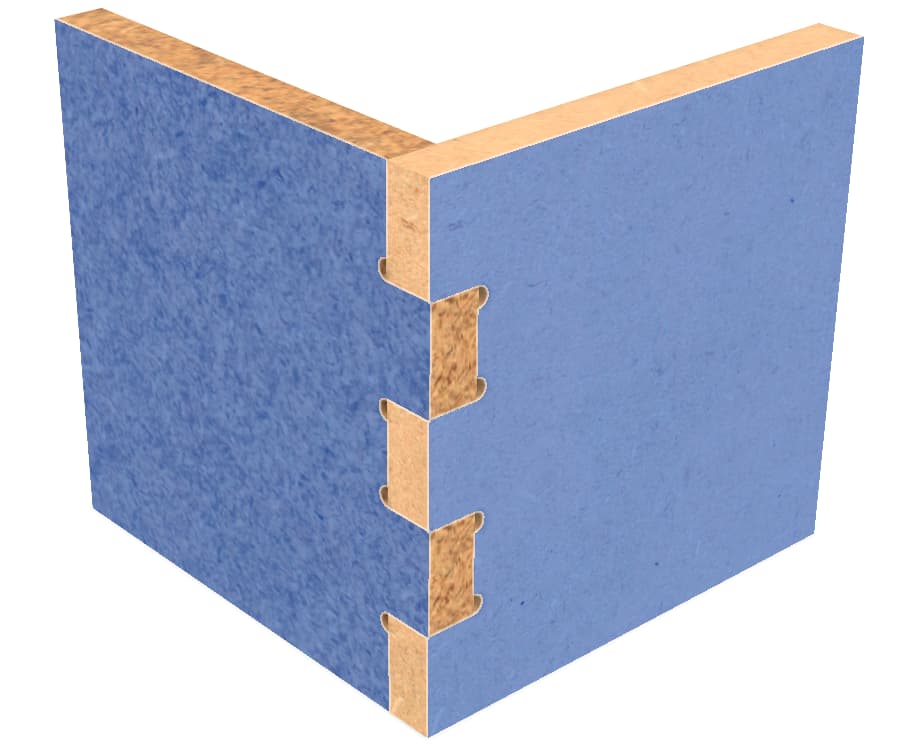

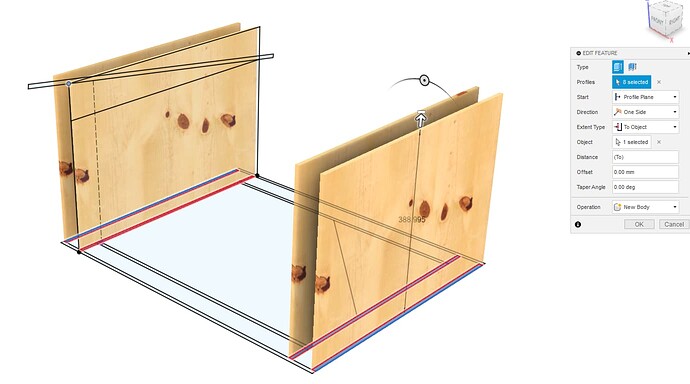

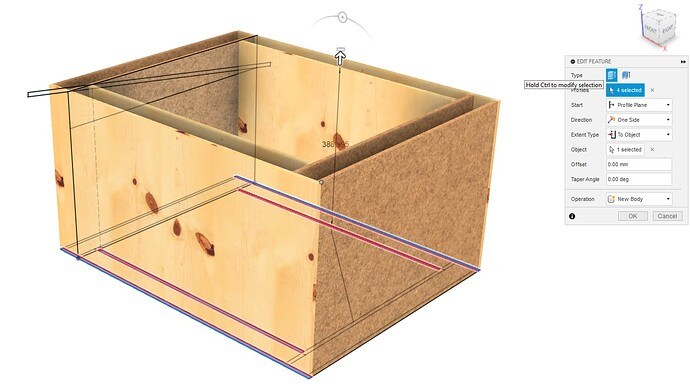

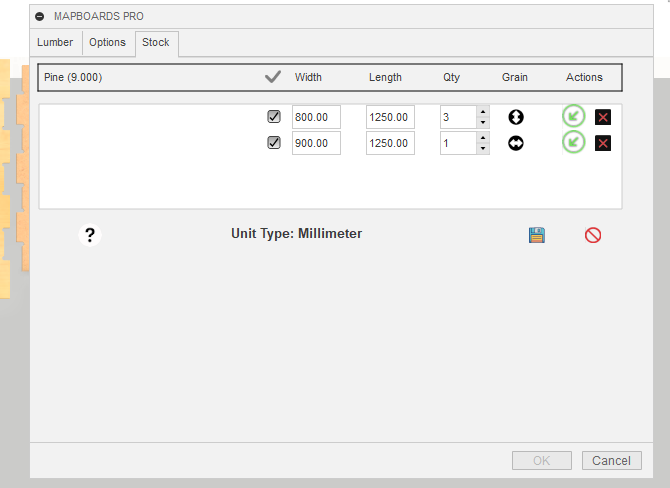

The build will use 9mm 3-plys OSB panels, assembled with finger joints, glued and screwed for reinforcement

Note: Different textures in the 3d model are only used to facilitate viewing the fingers

In-between walls, I’ll add some 45mm insulating foam, hence the double-walled structure

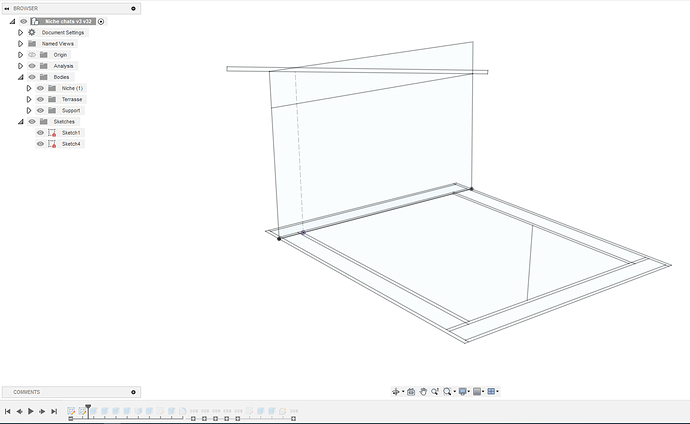

The whole structure is divided into 2 separate “modules” I can screw together, with a single common “roof” above

”Sleep module”

“Terrace module”

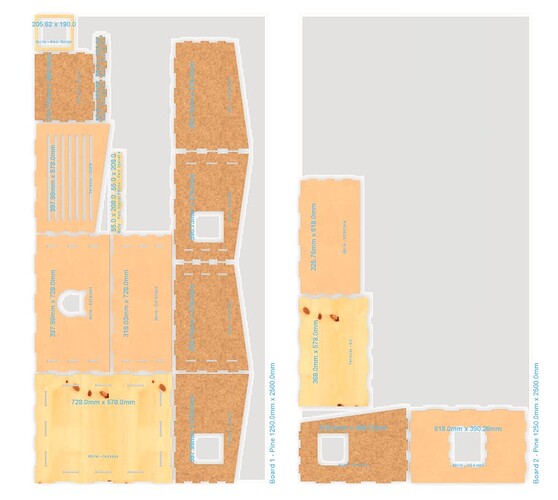

This allows me to have smaller parts , mainly for cost optimization (smaller stock needed)

This will also allow me to change some parts of the build if need be (eg: a larger terrace on the right side so that I can leave some food too)

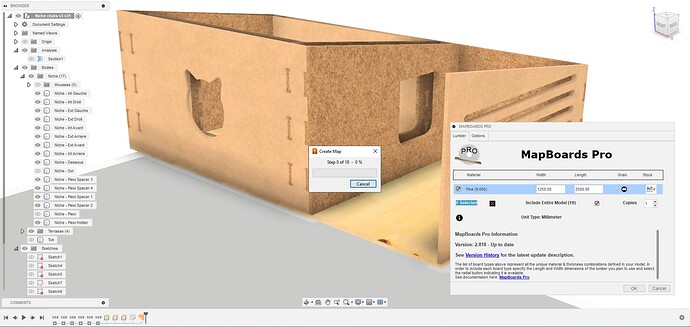

Modeling

The hardest part of this project is probably to design the fingers and corresponding holes.

I failed miserably at designing them at first, wasting 2 days with manually defined fingers that would break after every change in dimensions…

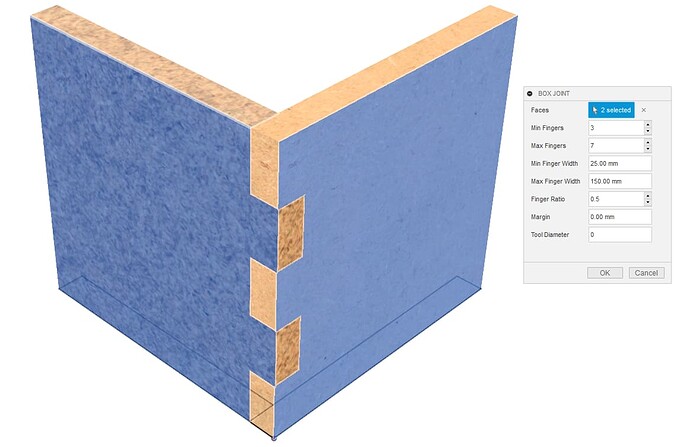

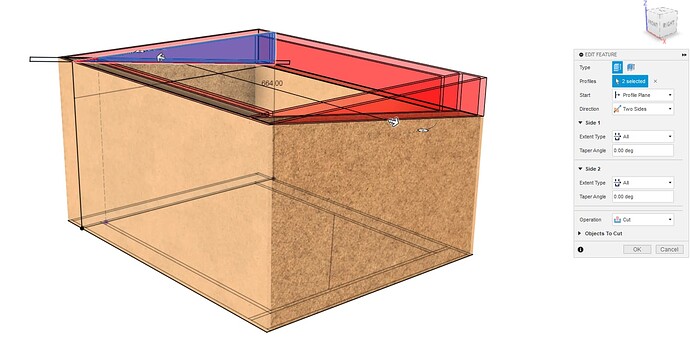

Then I discovered the “BoxJoint” plugin ![]()

BoxJoint Plugin

This plugin is a true holy grail !

It’s quite simple to use:

- First just model your two boards with a simple “butt joint”

- Click on the add-in

- Select the two faces you want to join

- Click OK… Boom! It’s done….

- Need to change some parameters? No problem, double-click on the feature in the timeline

And you know what’s the best part of this? It’s free! ![]()

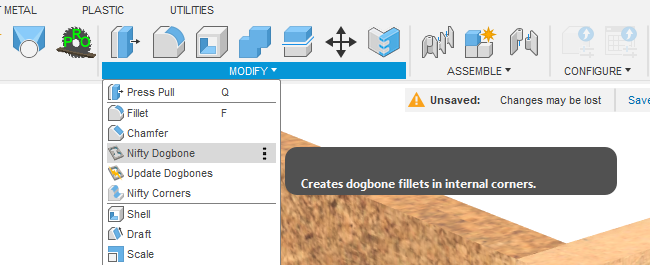

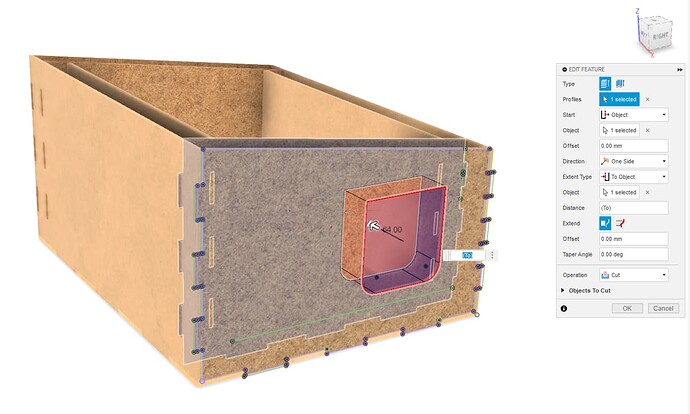

Dogbones Plugin

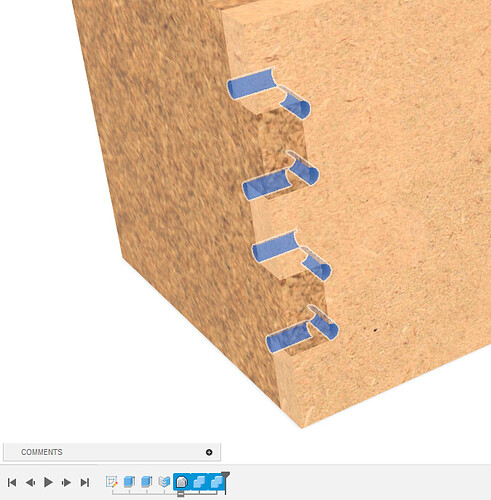

Now we have finger joints, but as you may already know, they’re not “machineable” as-is

The bit radius will keep them from sitting flush

We need to add “dogbones” to the holes and fingers to accomodate for the bit radius

I tried two plugins for this:

- DVE2000 Dogbone - GitHub - DVE2000/Dogbone: A Fusion360 addin that creates dogbone joints for wood joinery.

- Nifty Dogbones - Nifty Dogbone for Autodesk® Fusion® | Fusion | Autodesk App Store

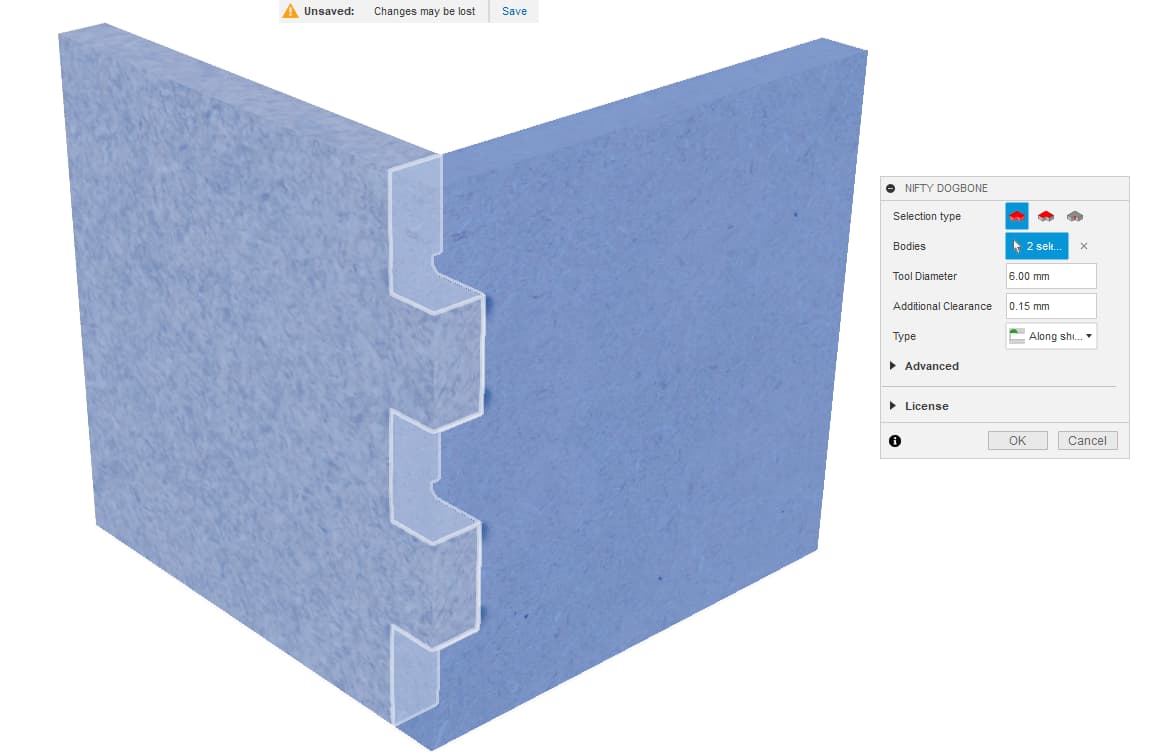

Both plugin do the exact samle thing, and have the exact same options

Thay also have the same flaw;

it’s only a script that generates dogbones as a one-time operation, and you can’t modify the parameters later. You’ll have to delete the feature group and re-do the process.

The first one is free and open-source, and worked fine at first.

But it totally failed later in the project and I was unable to update or even re-model the dogbones, Fusion360 would just crash every time…

The second one is paid (20$) and I suspect it’s heavily based on the first one…

It’s a lot faster and more stable though, so I may end-up buying it anyway…

Here’s how it goes:

- Select the plugin

- Select the two (or more) faces/bodies where you need your dogbones added

- Click OK, done.

Note: As mentioned, the resulting feature will be a group of operation without any mean to edit or modify the parameters. I’d be quite ok with that for the free plugin, but I think it’s a bit of a shame for the $20 one

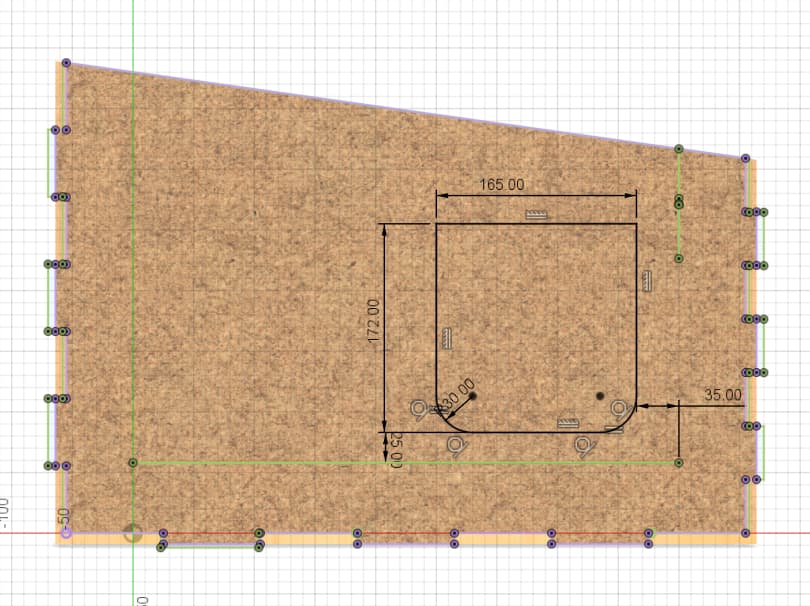

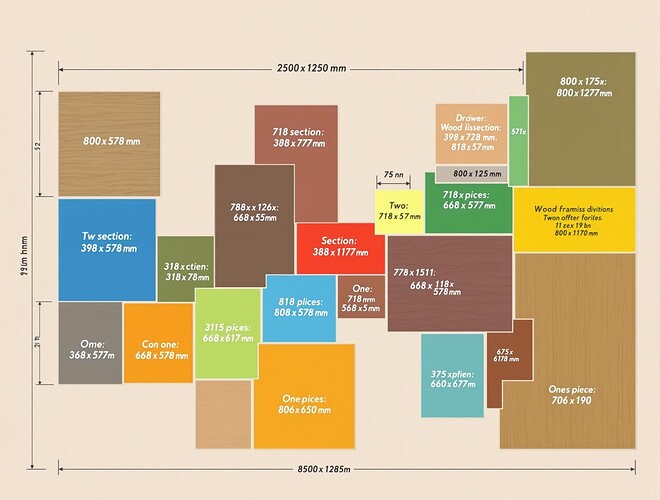

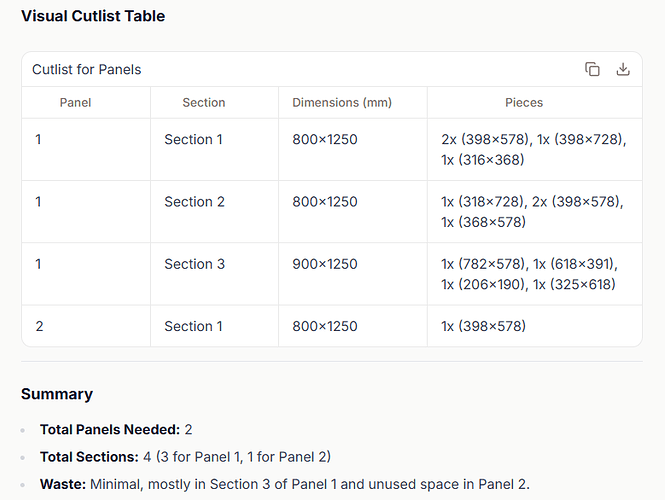

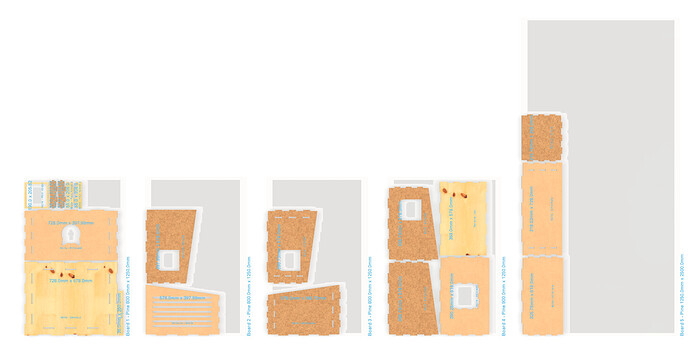

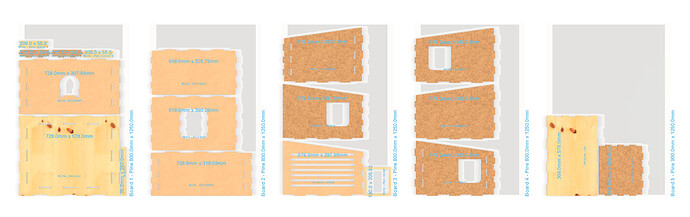

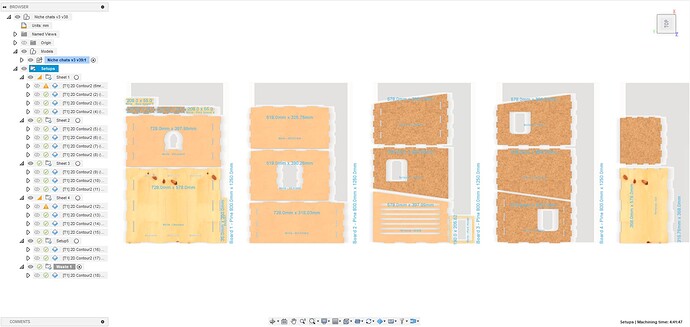

Layout

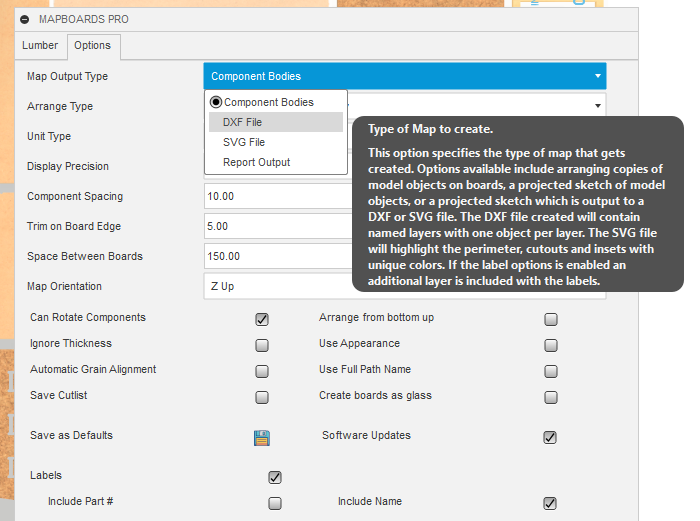

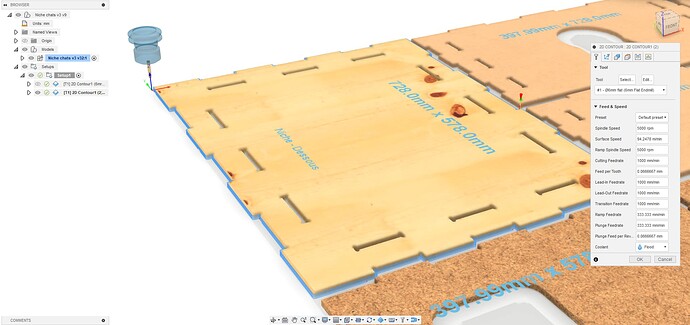

As usual, I use the trusty “MapsBoard Pro” plugin to create the layout for machining

Next steps ?

This is just an “ongoing thread” to document this project

I just wanted to share some activity and cool findings with thos plugins

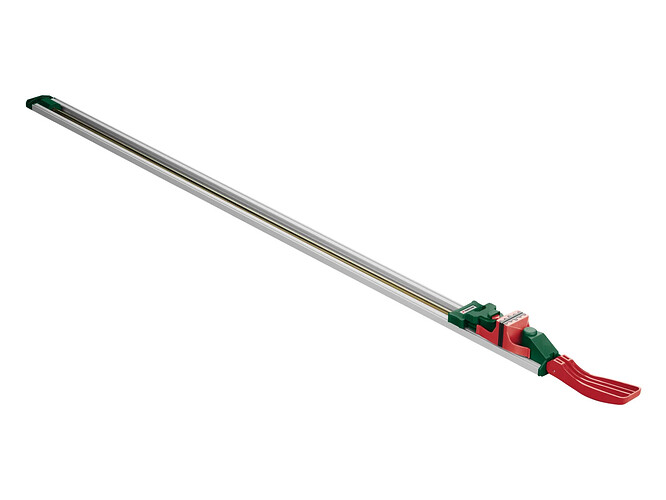

Now I need to buy the OSB sheets, break them into manageable dimensions, dust off the LR3, and cut all of this ![]()

I’ll keep you posted ![]()