Hi,

is Yours guideline on thingiverse updated ? I would like to make Your engraver.

Thank You.

What are you referring to when you say guideline? All the STL files are updated except for the Eleksmaker & Pi side mounts. I had one problem with the Pi side mount. The belt along the 2020 is extends 4mm beyond the edge of the 2020 where the Pi mounts. I am making 6mm spacer that should work for that. rather than having to print the case with an overhang and support.

I bought a new 300mmx300mmx400mm Zyltech 3d printer this week from the 18% Halloween sale & that might side track me from working on this. It was $346 with the shipping cost.

Hi, if I make engraver as You have on Thingiverse. Will I have Yours last tuned version?

Thank You for Your Great job.

I have published my remixed version of Daves design here- https://www.thingiverse.com/thing:4645406

Hello,

Do you have a tutorial for the programming, wiring, software part?

thank you

@meatball I just bought a bunch of 2020 to play with so I was going to go with your design but when I printed the X gantry the spacing between the wheels was too small. I could not even get it slide on to the end of the extrusion. Is this meant for the same 23-24ish mm wheels used in the original design?

The wiring for the keyestudio board is shown in message #90 of this thread. There is also an image of it on the thingiverse upload: https://www.thingiverse.com/thing:4605853 If you are using the eleksmaker board it should be fairly simple. I can give you the grbl settings I am using for a starting point, but they will probably be a little different depending on the drivers you use & the size of the machine you are making.

@géodave Thanks for your quick response, I wish to make myself a bigger laser engraver than the one I currently have. I can be able to recover parts above (personal question).

for information I have a Neje Master 2 laser engraver of 7w

I have a 3D printer, but I don’t know anything about wiring programming, arduino etc … that’s why I asked for a tutorial :).

I want all the data you can give me, links, videos etc … thank you

And to complicate matters, I don’t speak English well, thank you google translate.

thanks again

Sorry, but I have given all the info that I currently have on this project.

Hi,

What do you think of this card ?

Apparently all you have to do is plug in the stepper motors, the laser, and the power supply; to make it work … Your opinion? Seems too simple to me, right ?

Add :

I spoke with the seller, this is what he shared with me.

If that can help you … And for you to confirm back to me that it is as easy as what he told me (i’m new to programming but i want to learn)

Nope…it really is that simple! The only question mark I might raise is that the input power is rated at 12 - 24V and the laser will not like anything over 12V and as they don’t show the bottom of the board I would just check that there is a regulator there to drop the 24v to 12v if you intend to use 24v…better still…just use a regulated brick PSU of 12V @~3A.

Most of that software linked is somewhere between poor to useless. You may need the CH340 driver if you haven’t used a clone nano before on your computer, for the rest I would give it a miss. I recommend you look at LaserGRBL or LightBurn for software.

You don’t need the ‘offline’ board as those functions are also provided by the software.

Also…do yourself a favour and follow their example of buying a laser module with an integral controller board like these, not one of the lasers that have a separate ‘brick’ psu/controller…like these

for the input power: 12V-24V in the description.

For the laser power output, we can read; LSR / TTL 12V GND PWM.

i dont know about the amperage i can ask the seller.

Why not a separate controller?

I have a neje laser master 2, I believe that the controller is separated, I can reuse it with the card that I showed you?

I would like to make myself a laser engraver with a larger working area, perhaps by reusing part of my current engraver.

the card works with LaserGRBL told me the seller.

Firmware: GRBL (1.1)

Input power: 12V-24V

X / Y axis: 1 * X axis, 2 * Y axis, dual Y axis support 2 stepper motor

Support laser: 500mw-15000mw (Almost support all kinds of laser in marsket, you can connect us to confirm)

Software: LaserGRBL, Laser engraver, GRBL

System: Win7 and above, XP, MAC

Servo: support write function

Offline: Support offline work (no need to connect to PC)

OK… forget what I said as I obviously confused you…it will be fine. If you already have a Neje lasermaster 2 you can use the power supply from that, along with the laser module…no problems at all.

If you just want a larger engraver you could just buy a longer lengths of 2020 extrusion and GT2 belt and fit those to your lasermaster 2…both X and Y carriages if you want.

I will test and I will come back to know my results here

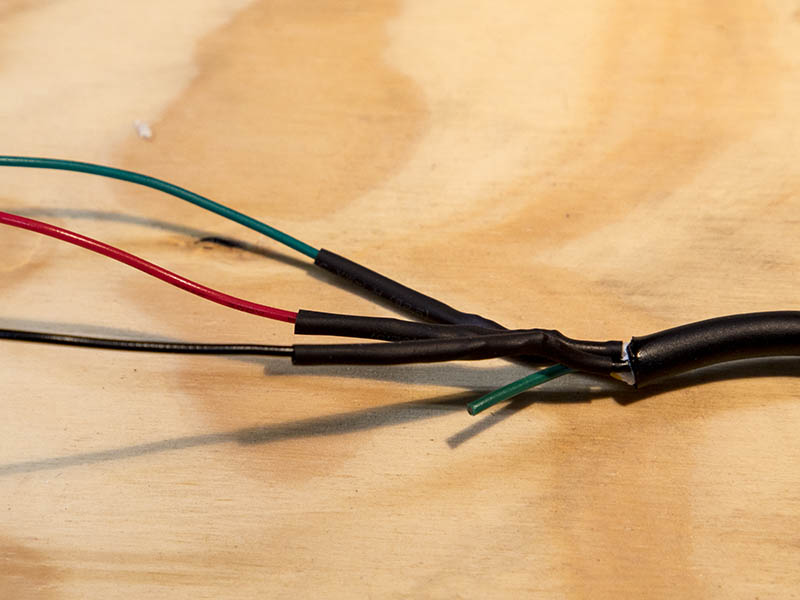

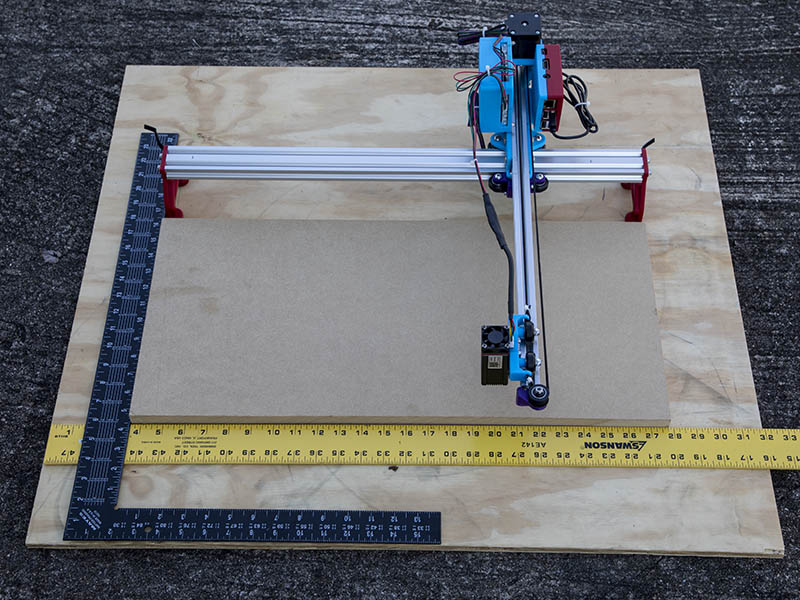

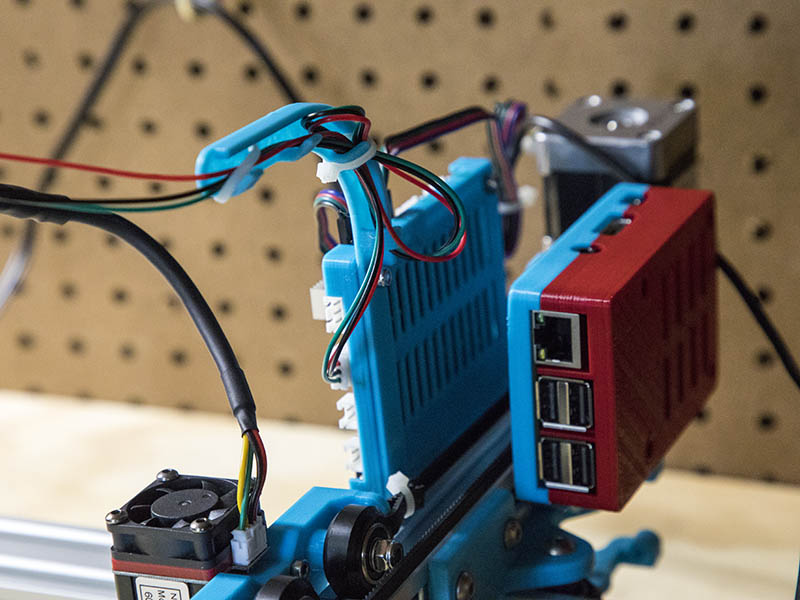

I finally got the wiring done and will probably do my 1st burn test tomorrow. I forgot to put heat shrink on the 1st wire before I soldered them together, but was able to pull that one out of the plug & put it back in after putting on the heat shrink. Luckily I only did that before soldering the other 2 wires. I set the VREFs on the DRV8825s before putting that case on. I had a spare piece of MDF which was a good size & if it is not too short a burn distance will use that as the flat surface to burn projects on. Here are a couple of photos.

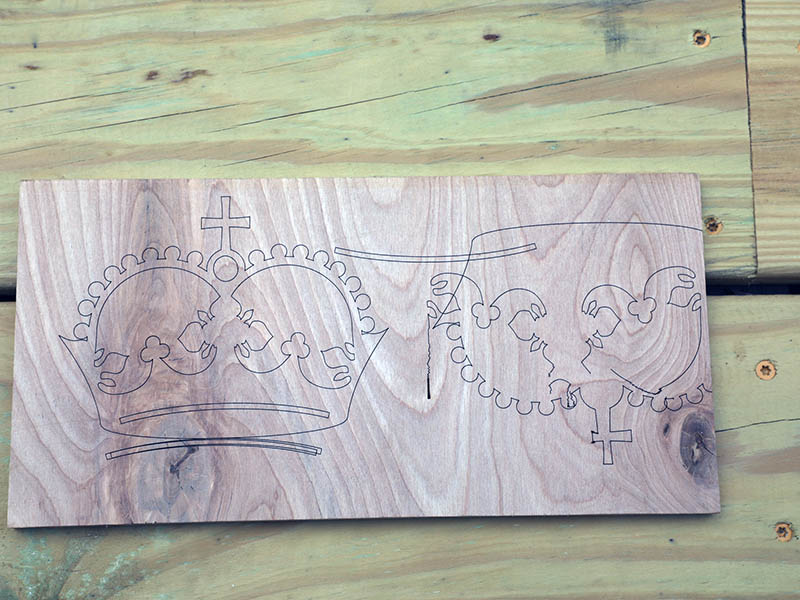

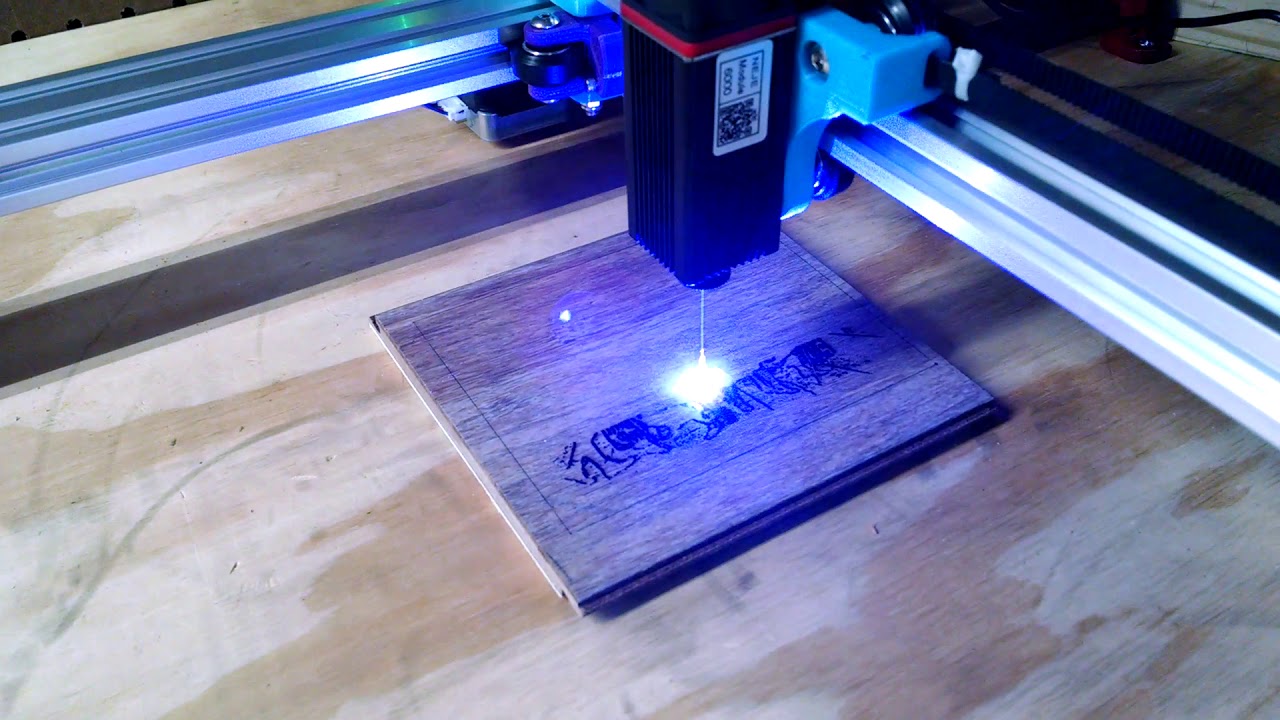

I was going to use .9 degree motors I had bought this summer, but they did not seem to want to move, so swapped them for the motors I was originally testing & everything is fine now. Will have to test those motors again on a spare board to see if they do work. I found the crown laser test gcode and ran that today. I had to change M106 S255 to M4 S1000 & M107 to M4 S0. I thought S255 was the high number, but was not burning much, so then tried S1000 & it looked good. The 1st test I was not watching it the whole time, but seems to have caught on one of the wires when moving. I will have to create some better wire management. Here is a photo of the test burn. Looks pretty sharp to me.

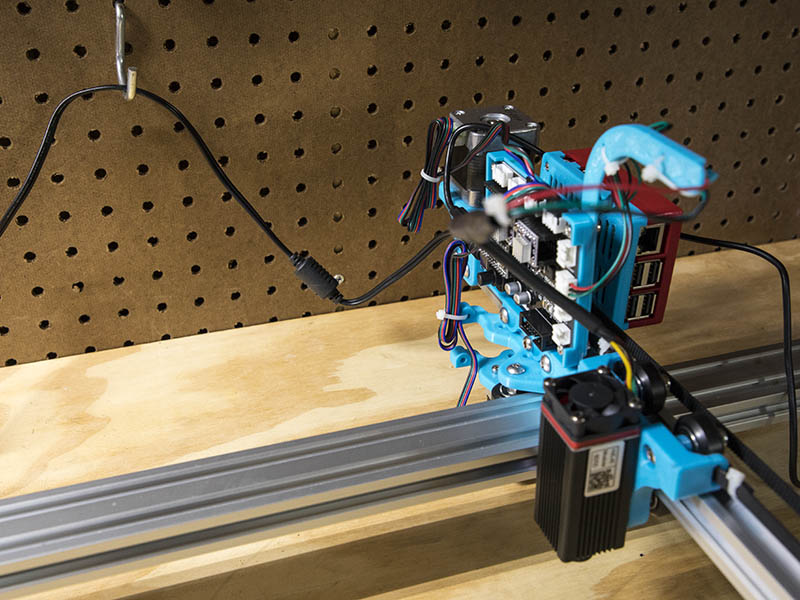

I added a wire management channel for the laser wire & seems to work good. It is attached to 2 screw connections on the controller board.

Here is a video of it burning an image using Lightburn. The image mode is Sketch. This is running at 100mm/sec & 90% power. Probably need to adjust those numbers. I used my 6 year old phone camera instead of my real camera to video this in case the laser was not good for the camera.

This was from a halloween photo from a couple of years ago of a group of witches. First photo was hot off the laser, the 2nd one is sanded a little with 220 grit. Looks like I have room to improve. I made the rectangle outline 5"x4"(127mmx101.6mm & it measures perfectly & diagonals are same length, so it seems pretty square. I probably should do a maximum size Rectangle to really test the squareness. This burn took around 2.5 hours. Probably could have run it faster and had finer detail.

I have the legs screwed down to the board & did notice that I can flex the end legs. It does not seem to affect the engraving though. I placed an order with Misumi today for the extrusions for an enclosure and added 2 -2080x400mm lengths to the order to use for the legs. Since I did have the height of that 2040 at 80.7mm, 2080 works out well. That will get rid of any flex & also make it possible to make this more portable. I can foresee putting this on one of the new deck boards in a corner or two & burning a design. I had first thought about using a couple of 2x4’s for the legs, but drilling and counter sinking for the M5 screws could easily be off. While I am waiting on the aluminum, I might work on a drill jig design for the 2x4’s to see if it work.

I just realized this morning that a pocket hole drill bit would be perfect for drilling these holes in the 2x4 & I have one. Will try that on my drill press after I make jig for it.

Covering with transfer tape or masking tape prior to running the laser job can help keep the soot off of the surface around the engraving. But then you have to pick it all off again…