It will be worth your while to learn a few things in Inkscape. It is a bit steep to start off which. So many features.

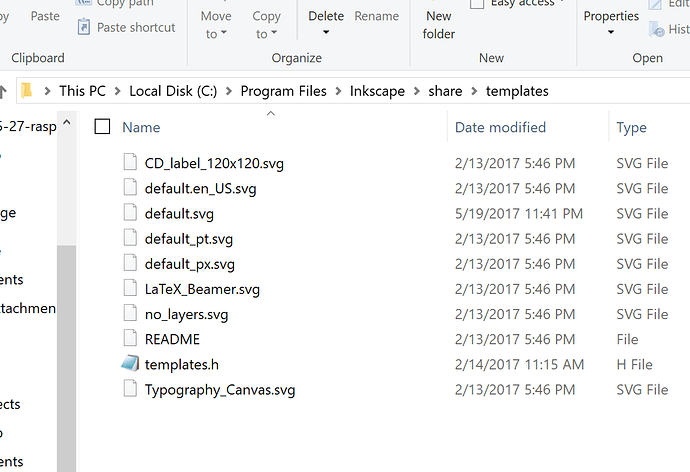

You can make a canvas the size of your usable space and save it as a document with the name “default.svg”. Set it up with the grids and dimensions that you would like.

Open up file manager in administrator mode and copy that into the templates directory in Program Files > Inkscape > share > templates

Now every time you open Inkscape, your default template will be for your CNC. I have a couple templates set up, one for my laser and one for my MPCNC. I use metric in the CNC but Imperial in the laser (or used to. Now I have switched to all metric but haven’t updated my template.)

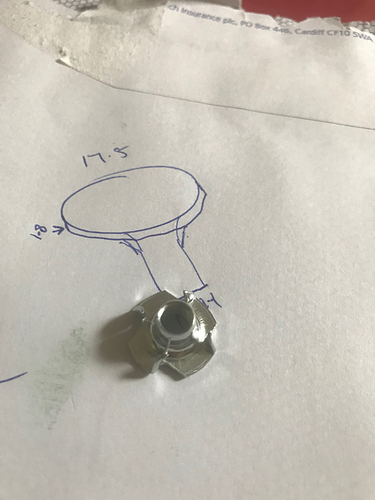

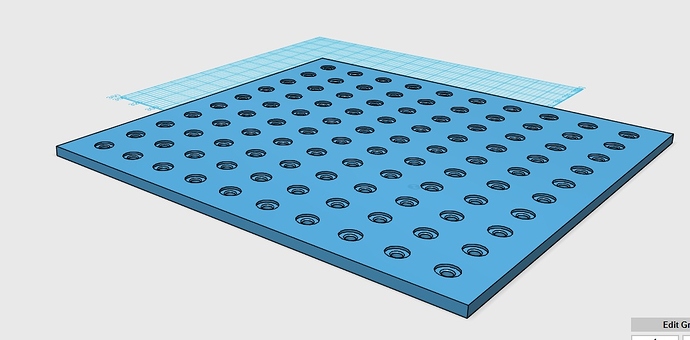

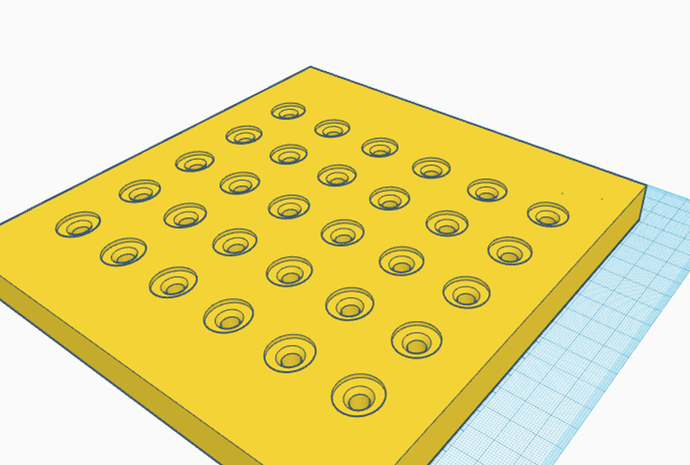

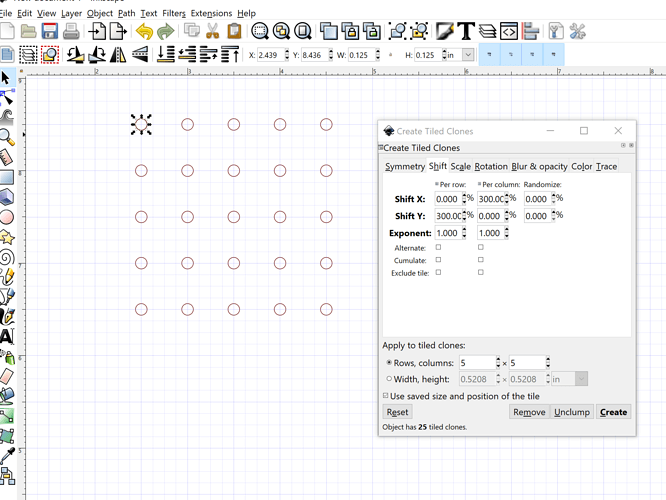

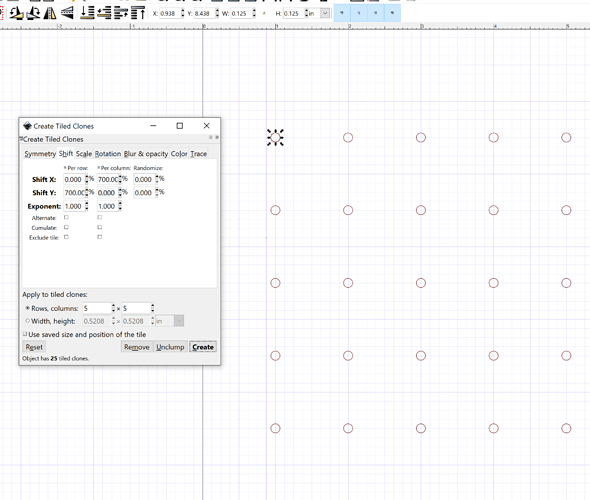

The other thing to learn about is the tiled clone tool which hangs out in the Edit menu. The way it uses percentages and messes with columns and rows and X and Y gets me a bit confused, but here is a setup that you can use to make an array of circles.

If you make a circle of .125". Then you can do a tile clone shifting each over and then down by 300%, you will get holes spaced exactly 0.5" apart.

Make the holes 700% apart and they will be spaced 1"

Don’t forget to delete the extra clone that is on top of your original object. Make sure you unlink all the cloned circles to make them individual objects or you will get just one circle in the final design. Do that by selecting all and then Edit > Clone > Unlink clone

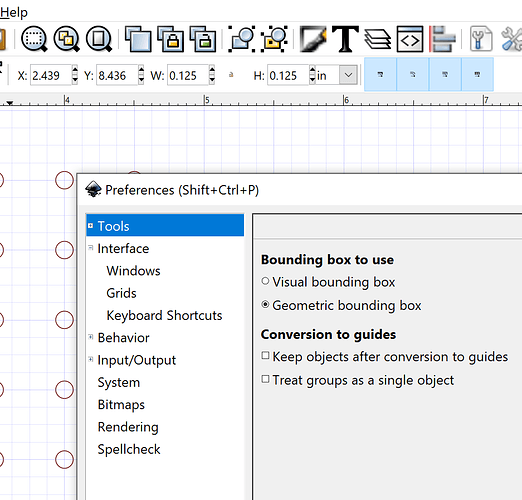

Make sure you are using geometric bounding box for measuring. That’s an obscure trip up that can through your measurements off. Found in Edit > Preferences > Tools What is going on is that measurement can either be from the center of each line or from the edge of each line so defining a 1" square can be done differently if your stroke width is wider or narrower.

The other way of doing holes is to make a bunch of them and do the align and distribute in the Object menu. Make all the holes you want and then put four of them at the corners of where you want the grid to be, then align and distribute. A little more complicated but great for when you are filling a known space.

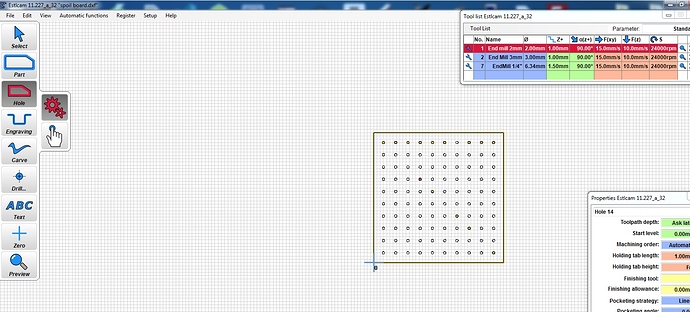

Oh, and this will give you a lot of holes to define toolpaths for. EstlCAM’s tiling function is much more efficient, but as noted, you can define all of them at once by selecting all the objects.