That’s great to know, thanks @Michael_Melancon. Am changing idlers to be smooth on my v4 based on yours and others observations/learnings. No rush, am not starting v5 just yet, am still figuring out material options.

Edit: Changing to smooth idlers on my v4 did result in minor improvement, less VFA but only if you look real hard under the right lighting.

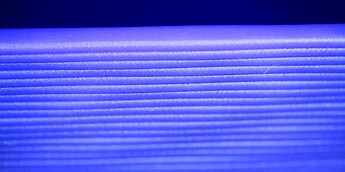

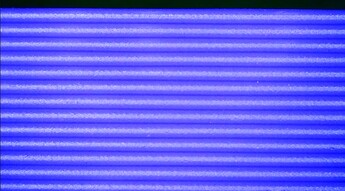

The ripple pattern I was actually chasing remains, the ripple varies with print speed. Not seeing same ripple on my slower much quieter ender 3 max, so, am taking another look at XY stepper config details, and BIQU H2 V2S extruder stepper too.

Am blaming a recent neat super slow motion vid for inspiring me to take another deeper look into these minor quirks don’t actually impact print strength/functionality…

High fps in that video helps reveal things like bad micro stepping interpolation causing jitter motion or extrusion.

EDIT #2: Recorded bunch of super slow mo videos using highest fps possible with phones I have on hand, they’re no where close to the 1000 fps in the mentioned YT video. However, did learn/realize amongst other things, that my XY1 and XY2 belts have unequal tension (inferred based on how they wobble differently during various motion directions, also, they play different notes when twanged). My belts have unequal tension because I’ve been physically squaring the X rail using the bolt adjustable stepper mounts.

Instead, I’ll prioritize ensuring frame is as square as I can measure, then, ensure equal belt tension for both loops (some how?), then, address XY skew using firmware configured compensation based on Calilantern test prints.

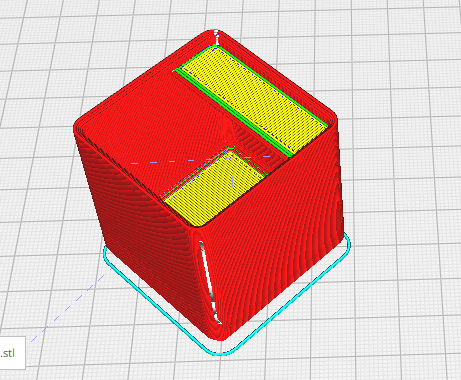

Rather than piss away filament on benchys am printing more useful 1x1x42mm gridfinity containers with each test iteration.

EDIT#3:

Tweaked more extruder and stepper settings.

Same behavior whether Gridfinity cube in default orientation or rotated 45 degrees (to help detect whether one belt is contributing to ripple more).

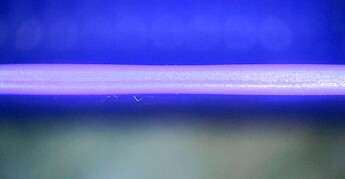

Closer look…

Overhead of 1 line wall looks like extrusion width periodically varies to me…

Ripple pitch period is more than 2mm, looks like ~3.5mm (measured ~12 ripples across 42mm surface), will see if any of the extruder gear/bearing internals match.

Will try adjusting tensioner and some other things based on misc guides (e.g. Ellis’ guide ) and ChatGPT suggestions. Failing that, will strip down and clean BIQU V2 H2S extruder down, again…

Also tried 400fps camera with Macro lens, still getting used to that setup, but haven’t learnt much from that yet. Much higher fps would be ideal, but haven’t found reasonably priced HW, prices go up fast. Would appreciate recommendations for 1000fps (or faster) setups that don’t cost $$$?

Checked g-code line segments are simple straightforward runs, so am not blaming splicer.