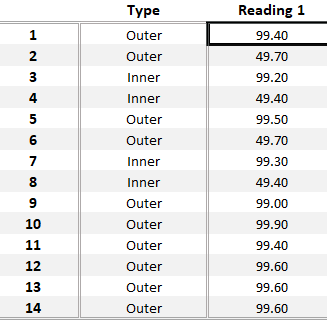

Hello. this is the result of my calilantern. seems very minimal to be an issue or better i correct before printing large parts of LR4?

but i don’t know how i can use this generated code

please help. thanks

Hello. this is the result of my calilantern. seems very minimal to be an issue or better i correct before printing large parts of LR4?

but i don’t know how i can use this generated code

please help. thanks

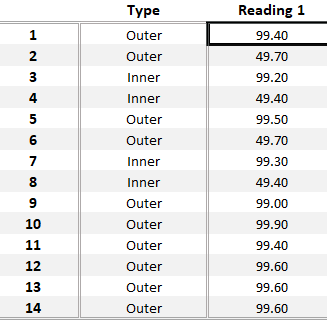

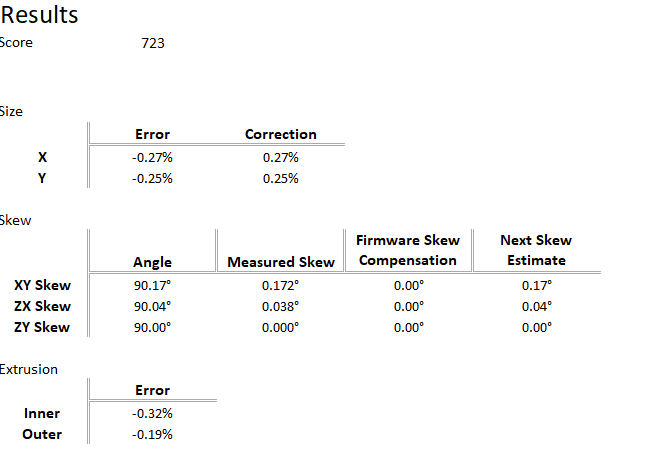

You’ve posted the readings you’ve taken, not the result it’s telling you. Please post the results, they’re a bit further down the page and under the heading ‘Results’.

They should look like this:

As for how to use the corrections, that depends on what your printer is and how its controlled. I haven’t done that part yet so can’t really assist too far but for a Marlin based printer, the sections with ‘to firmware’ at the end would lead me to believe that these needed to be added into the firmware for the printer and recompiled/flashed, which is probably where I’d start doing some reading.

this one?

That’s the one. Those are the results of all the measurements and showing how out the printer is.

I’m not sure what’s considered acceptable or not, so that’s probably the first thing to find out.

hello experts. any advice please so i can proceed printing ![]() . thank you

. thank you

Your XY Skew seems kinda big.

Also it might be that your X and y size could use some adjustments

But I’ll let others comment on whether you are close enough now, or whether you should apply some settings changes to compensate.

Note also that getting 2 decimal measurement accuracy for millimeters is pretty challenging, so chasing zero is not something that you necessarily need to do.

up up

The PDF file has the specific instructions on how to flash your Marlin with the changes, I believe. I use Klipper so it is a different method.

i don’t have that PDF file, when i download it, only the stl, excel file and change notes.txt i received

Check carefully that the PDF is separate in the downloads. It is very well explained. As Bartman says, I think the XY Skew is the one you should pay attention to.

when i purchased, i did not create a vector 3d account, i just click the link they emailed me and was able to download the files but that PDF guide was not included.

just now i create a vector3d account…and the pdf guide shows

Thank you! if it wasn’t for that screenshot, i will not create an account

another problem, i cannot find 29.5mm, 30mm, or 32mm conduit here. the closest i found is 33mm.

What part of the world are you in? These sizes were designed mostly based on availability of material in North America and EU, but Australia/NZ users have been able to source materials.

southeast asia

Check with your local steel supplier, ask about DOM steel tubing, see what sizes (Outside diameter or OD) are available

Note that conduit is typically referred to by the Inside Diameter(ID), so nominal 1" conduit is about 29.5mm OD, while Tubing is referred to by the OD, so 30mm tubing is 30mm

I am in Argentina, here the only thing I can get is 31.75 mm. But there is also the (much more expensive) option of stainless steel.

ok so for the XY skew. i tried to put a rectangular object in Autocad equivalent to the XY size of YZ_plate_max which is 190x173.5, then i rotated one side line to 0.172degee which is the value of my XY skew result.

upon measuring, it moved the other side to about half millimeter only. seems very small to be an issue? i think i can continue printing right?

I’m reluctant to say yay or nay, as I’m not an expert in this area. I haven’t used Calilantern, and I haven’t printed any LR4 parts. I seem to recall that Ryan (@vicious1 ) has said that people are worrying too much about Calilantern settings, and suggested doing a fit test by printing a certain part, but I can’t find that post in a search. Maybe I was imagining it…

Maybe someone who has calibrated their printer with Calilantern or who has printed out the LR4 can comment…?

Measure the diagonals, corner to corner. What is the difference?

That XY skew does not seem too bad, XZ YZ are the ones that are usually worse. IF you are familiar with firmware it is easy to get very close in marlin or klipper, if not you can make any parts work, it just tends to be better starting with better parts. Don’t over think it though.