I haven’t read that one but now that I looked it up it’s right up my alley of interest haha.

All I read these days is manuals lol

I recommend ‘The Kraken wakes’ as well. When you consider these were written in the 50s his themes are spookily relevant today (in my opinion)

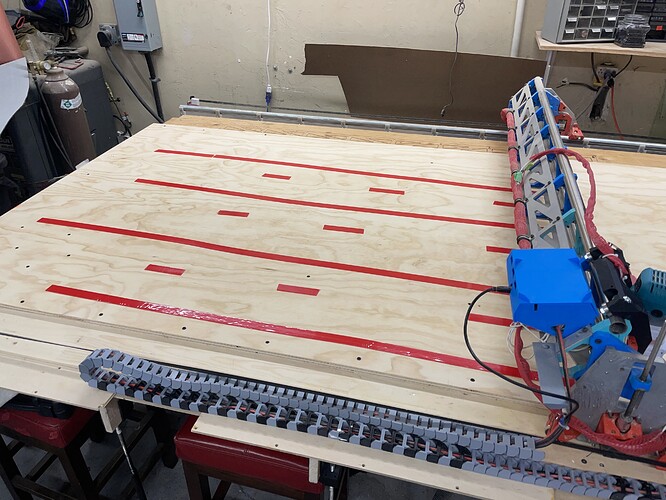

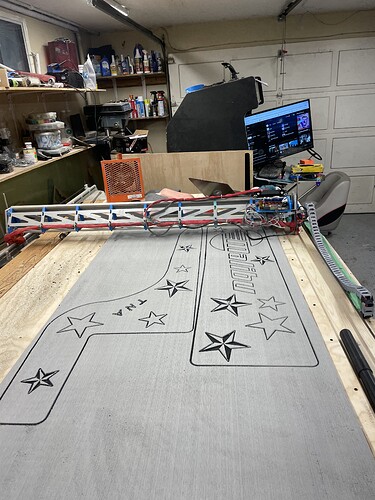

Some minor updates.

I managed to get my dash pieces in.

It’s not really related at all for Cnc.

But I will be doing some cuts very soon.

Ok so I got my roll stretching out and the backing is definitely different that the other stuff I had. This stuff nothing sticks to like you said. I am thinking it may have some kind of impregnated wax or something. I will try some chemicals and maybe scuffing it up a bit. If that doesn’t work I tried using the shiny side of my bbq butcher paper and it seems to stick well to the adhesive backing and has a paper back other side that the common double sided tapes sticks nice too. So I may just lay out that. Take the backing off the roll and transfer it to the butcher paper then trim and use that to stick down.

I will keep posting how things go.

I can’t remember how well it worked now because it has been so long, but I do remember that it did get better if I went over the backing with an orbital sander first

Well I removed the backing and put on some masking paper from work. And it’s looking like it’s going to work. It’s paper back and sticks well one side is shiny and waxed.

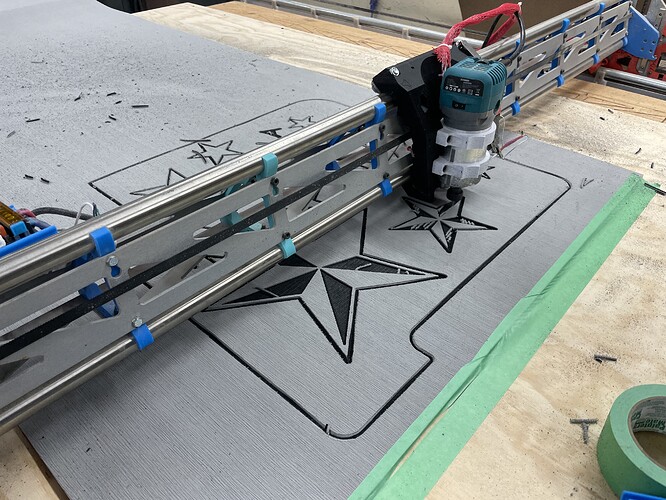

Well here goes nothing lol my sheet has been flattened out the backing is looking ok. I hope the double sided tape holds and is somewhat even. Using a vcarve I am forecasting a bit of a un even nightmare but let’s see how it goes.

That look so good!

Thank you it went well I was stressing a bit and just needed to get into it and try.

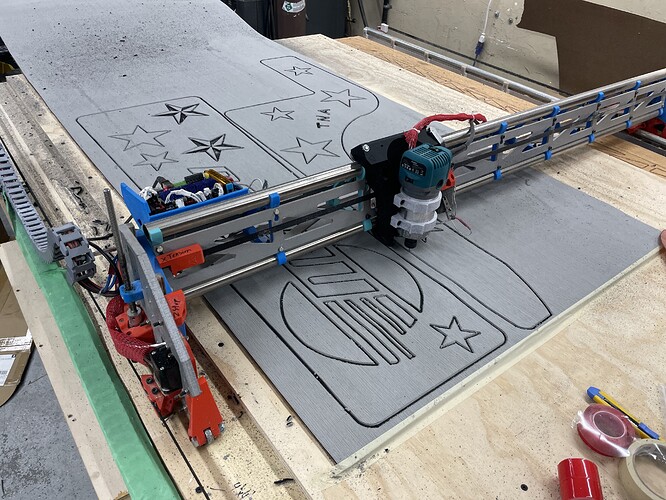

I ended up using a cheap like 1/4” router v bit that came with my router ( probably the cheesiest one ever lol)

It worked on a bit of fuzziness but I did two passes and it worked out good.

Your down cut 3.16 worked amazing at pocketing the foam it was so satisfying. I had to adjust the diameter to 2.75mm as I think my router is slightly a skewed.

Here is a video I have even added tacky music.

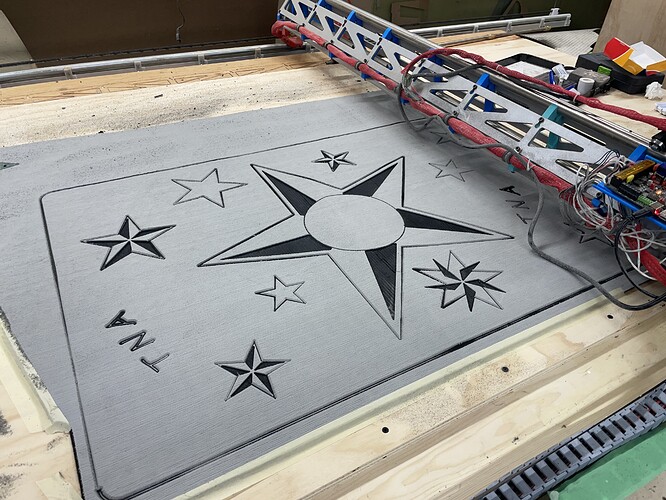

What is this material? Looks pretty cool

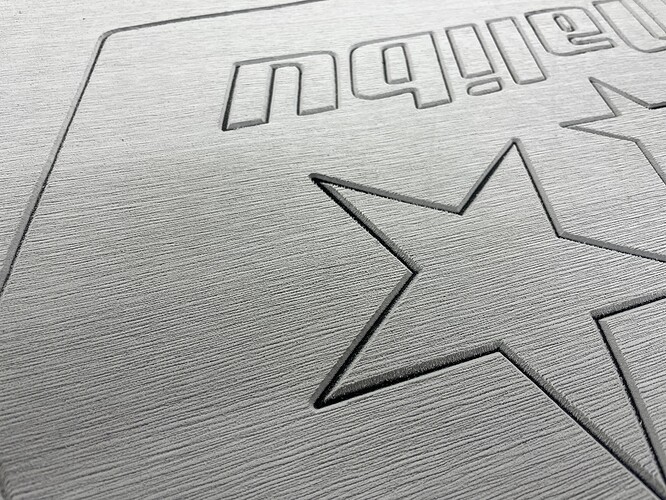

It’s the cheap Amazon Eva foam marine flooring.

2 tone

Grey is 2mm deep

Black is 3mm deep

And it has a sticky backing.

A couple of errors on this one but worked out ok enough for me. Learning lots still.

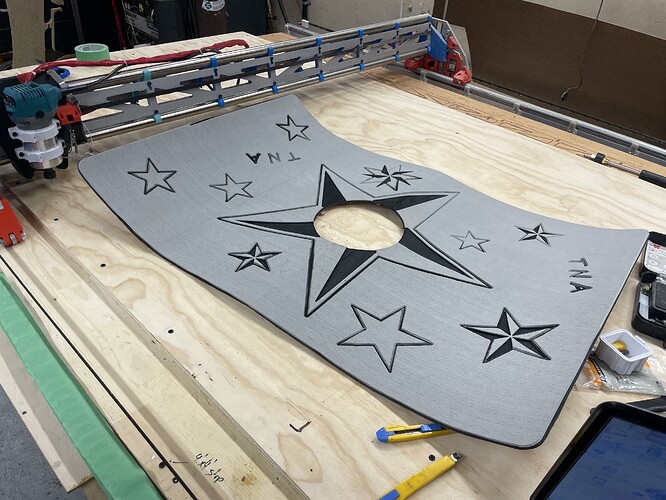

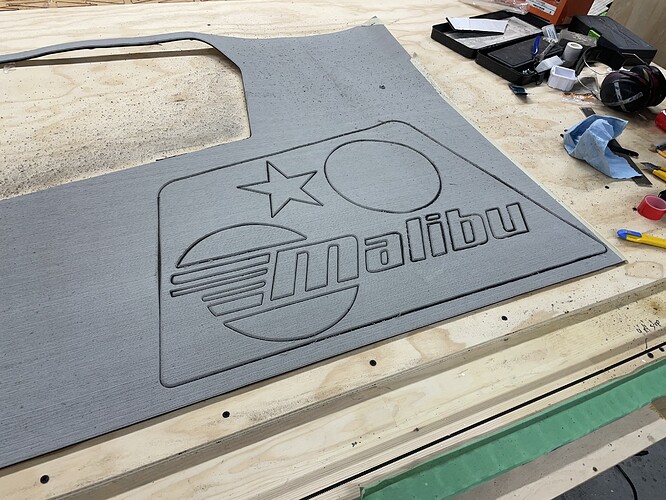

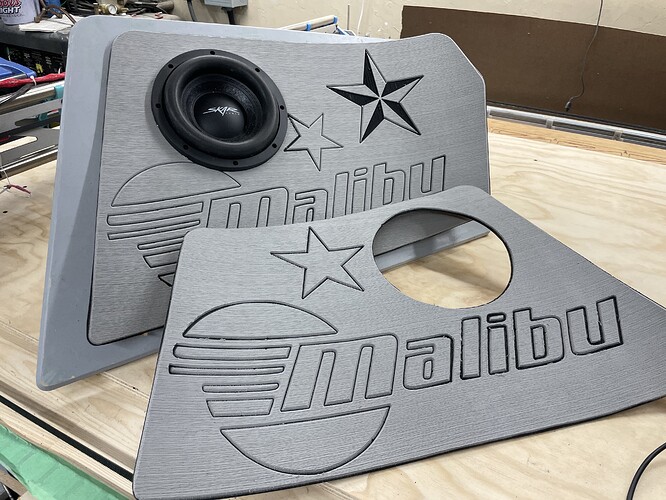

One more down I have a couple more floor pieces and then I can finish my speaker boxes.

Couple more sections done. Now the floor is technically done. I will move on to the side speaker box face panels. I have some left over single stage shop line white I am going to coat the boxes with. Hoping for a 2” border and a neat design on them as well.

Looks so clean

Thank you

I learnt so much on this project, and now I have a rhythm.

I love everything about this project - do you think it would stick over moulded anti-skid - or would I have to bog and sand the whole floor first. (Asking for a friend)

Well I think they want it pretty flat. And it’s just not for adhesion, apparently it’s also for corruption.

If the edges are not sealed things will get in kind of underneath and can make it delamn from what I have read.

I am new at this stuff tho