I’m looking for a simple electrical connector to terminate the stepper wires at the box that will house my control board and power supply. The connector will preferably be inexpensive with easy to crimp and insert pins. I have some Deutsch connectors but that seems like overkill. What are most people using?

I used these:

Aviation Plug GX12-6 6pin 12mm Male & Female Panel Metal Connector Amazon.com

Perfect. Are there pins to go with it or are they self-contained?

The wires are soldered to the connectors. No pins

Apologies for bringing this thread back from the dead. I bought some of the aviation plugs that Gene recommended only to learn that I don’t have the proper equipment, steadiness, talent, or patience to solder 30+ tiny little terminals. Does anyone have a recommendation for something similar that does not require soldering? Possibly a bulkhead connector with crimp terminals?

On a related topic, I’m also looking for a 12v bulkhead connector for the power to my board. I found something like this: https://www.mouser.com/ProductDetail/Switchcraft/761KS15?qs=fbkhFuCHoTZ5iIjOwAweAw%3D%3D&mgh=1&gclid=CjwKCAjw07qDBhBxEiwA6pPbHrqCk7-kO5nMZxpKcekXrDBYpf_3KjF1M8GX-MpYb5HLtcthp3XfNRoCfssQAvD_BwE

but it’s only rated for 5A and my power supply puts out 6A. Will that be a problem?

Maybe something like this: Lowrider2 Plasma Build

I’m with you, had no desire to solder those aviation connectors.

I used those red solder heat shrink all in ones, cut one end, place over terminals, then insert all 4 wires and heat

That might be the ticket. A tub of butt connectors is on the way (I thought I had some).

Anybody have some thoughts on the 12v bulkhead connector?

That is genius!

Is it foolproof?? My issue with those damn aviation connectors is I always manage to melt the black plastic with too much heat xfer through the pin. Did you have any issues like that at all with the heat gun?

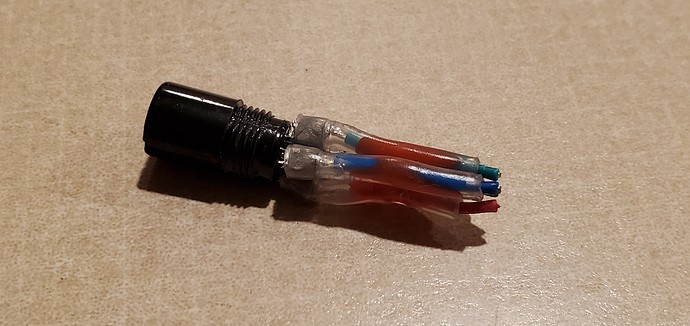

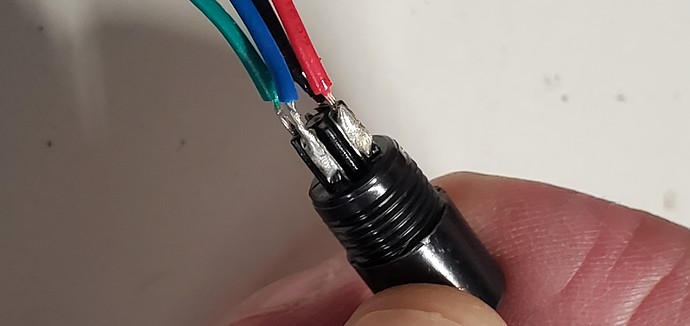

I really wanted to get these aviation connectors to work but I’m throwing in the towel. For starters, my connector looks different than the one above so even if I can get the butt connector to work there’s no way the outer sleeve will fit over the butt connector and thread onto the barrel.

The bigger problem is that when I get the butt connector properly melted I find continuity between adjacent pins. I even took the time to solder wires directly to the pins on the connector and still had continuity.

Clearly, soldering is not for me so it’s back to the search for a bulkhead connector with crimp attachment.

Better tools = better outcomes.

A common mistake is for a beginner to think that they don’t need the “fancy tool” because they don’t need the extra functionality that the inexpensive tool doesn’t have.

A temperature controlled soldering iron will give better outcomes than one that is full power all the time. (Took me a LONG time to learn that.) If you have sufficient skills, you can learn to use the simpler tool, but to avoid melting stuff you don’t want to, like a plastic barrel, there’s nothing like a temperature controlled soldering iron.

I have a bunch of small connectors, and though I would say my soldering skills are reasonable, I had very little success with SMD soldering and those little plastic connecters were a nightmare, because the metal pins were most of their mass. Heating them up to solder flow temperatures seemed to have a high rate of failure due to melting plastic.

A temperature controlled soldering iron fixed that for me, and I have much better odds of success now. It’s a matter of getting enough heat to the metal at the right rate. Too high temp, and it’s all on the surface, and the plastic gets too hot. Too low a temp, and it takes too long and the metal gets heat soaked, and melts the plastic. Also, flux is your friend. Rosin core solder is all well and good, but good flux makes a lot of difference.

Those melt in place heat shrink tubes work well for wires, never tried them on plugs. I’ve used them in the car, but just heated them with a lighter.

For your needs, you might want to consider a screw terminal or similar. These are a little bulkier, and really meant for much higher voltages, but can be used to keep stuff separate inside and out.

Alternately, consider something like a DB25 connector which should have room for 5 motors (4 pins each = 20 pins) and 4 endstops with a common ground. Or of course you could use one DB25 for the motors and a DB9 for the endstops. (Hmmm, with the pins, these get expensive. I always got the solder type, but then we’re back to the first problem.)

Totally agree.

However, the tool is just one of several things I lack for making a good solder joint. I would like to avoid investing in a good solder set-up for a one-time job but if I can’t find a decent crimp connector, that will be plan B.

I did find these connectors that may or may not work:

https://www.amazon.com/gp/product/B07B7H6L7Q/ref=ox_sc_act_title_1?smid=A2OW61D9G6Y4VD&psc=1

A little more than I wanted to spend but if it means that I can get back to working on other projects that’s money well-spent.

First, you’re totally fine avoiding soldering. This is your project, and your time, and you should find a way to enjoy it. A lot of people that don’t like soldering just buy the wires from V1 without using any kind of special connectors.

But, I want to tell you what I think makes a big difference in soldering and what doesn’t. I find that a bench top soldering iron with the iron on a wire works pretty well, even for very fine soldering. Having a temperature control is a must, but the brand doesn’t matter. You don’t need to have decades of experience to make a decent soldering iron. Replaceable tips and a few assorted ones are fine. The small tip is pretty much the only one I use. Some of the amazon ones are about $50 and they are great.

Second is that the solder itself matters. Thin, higher quality solder makes a huge difference. The demo stuff that comes with irons is garbage.

Third is the technique. For soldering connectors, put some solder on the tip of the iron, and then “tin” the wire and the connector first (that just means heat them up and cover them with solder before connecting the wire). Then you can clamp the connector to something, and hold the wire in one hand and the iron in the other. Put the wire on the connector, hold the iron there until the wire sinks in and then holds nicely. That’s it. You can try this technique with the tools you have. But really, if you plan on soldering something 1/year, an iron and a spool of solder will last you your life and 30 connections will be done in 20 mins whenever you need to.

Something like this looks pretty good. The solder is 1mm diameter, which would work, but a 0.5mm diameter would make it easier:

https://www.amazon.com/LONOVE-Soldering-Iron-Station-Kit/dp/B08J7VLJ49/

This is totally preachy, I know. You’ve said more than once that you’re not interested in soldering. It is just hard for me (and probably Dan) to ignore, because I have such a low barrier to soldering and 30 connectors doesn’t seem bad to me at all. Even if it doesn’t convince you, maybe some future person will appreciate the alternative perspective.

I’m a solder guy as well, who does smd work regularly. So my opinion on what is doable is probably not very popular. However I did want to mention you have to be cautious when using those heat shrink solder joint products. Those things contain a special blend of solder that melts at very low temps. This is required to work with the shrink tubing; it must stay below the melting point of the heatshrink to form a joint. So the resulting joints will always be weaker/higher resistance than say a traditionally ironed 63/37 rosin core joint. That said, if you are sure you are getting decent wetting on both surfaces, they may not be anything to worry about. I would at least give them a good yank and twist before leaving them be… make sure the wire doesn’t move even a hair inside there.

I personally decided against using bulkhead connectors on my box for a several reasons; 1) my box is more or less permanently mounted to the cnc table (so connectors are not required), 2) the box did not need to be IP-65 as it will never get powerwashed, 3) every additional connector adds another failure point, 4) auto square with all the toppings would need a somewhat portly panel to fit all the required connectors (a massive hard to work with printer style plug with low ampacity was not appealing either), 5) properly manufactured (truly reliable) aviation connectors are pricey, and last but not least 6) I did not want to purchase shoddy mystery material connectors from overseas (legit av conns do not melt when you solder them, lol).

So instead I simply ran my loom straight in through some smoothened slots on the side of the box, and added some ziptie anchors for strain relief. All my wires are unbroken, and run directly from a solder joint on the business end, to a Phoenix Contact brand screw terminal on my controller. The wire passages on the box have extra room and are easy to work with; no soldering or drilling needed to add a feature later on. A filtered fan keeps positive pressure in the box during operation. So it stays dust free inside, even when I cut MDF.

TLDR… it would probably look much cooler if it did have aviation plugs though.

You guys are going to make me solder, aren’t you?

I’ve been resisting it but I’m going to order a decent iron and give it one last try. If I still have problems, I’m going Kev’s route!

+1 for Kev’s route. Fwiw in my atypical build my stepper wires just come up through a hole in the bottom of the electrical box all the way to the controller. I haven’t ever built one but I think @vicious1’s 3d printed electronic enclosures also just route the wire straight to the board, no intermediate connectors.

Ultimately, for all I said, I have not bulkhead connectors for my MPCNC. Same thing, cables go straight to the control board with no intermediary connector. Actually, I’m still waffling on an enclosure, so it’s even worse right now.

I am planning a re-wire though. With the wiring kit, and the distances involved, there are too many connectors in the chain for my liking, and I have occasional errors in my limit switches, because one of the crimp connectors seems to be iffy. I’m going to try to wire everything with as few connectors as possible and see how that goes.

Fool proof for me I did like 14 connectors with 5 wires on each, no issue… I did have to pick the odd solder ball out that flows out of the tubing… My connectors were also twist lock. A small nub u line up and turn 1/8 turn the lock in with an ultra small screw

Great success! I got a decent soldering iron with adjustable temp and breezed through the connections. Never was the phrase “the right tool for the right job” more applicable. I may even use the aviation connector for my 12V input to the control box.

Thanks to everyone for the advice! More dumb questions to come.