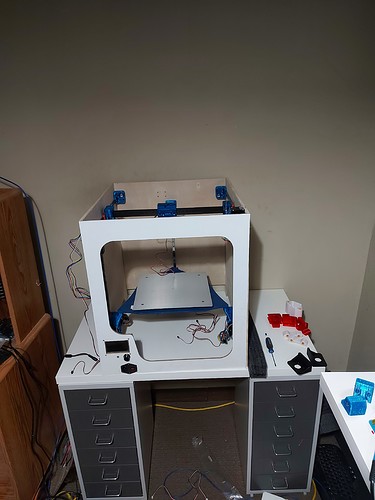

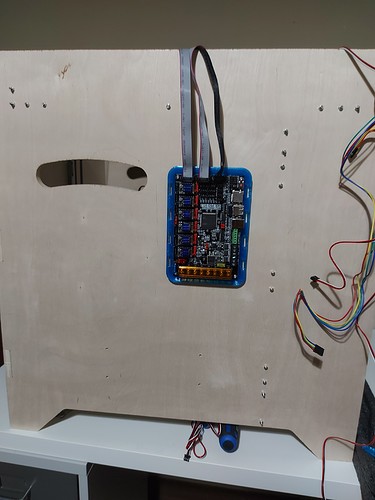

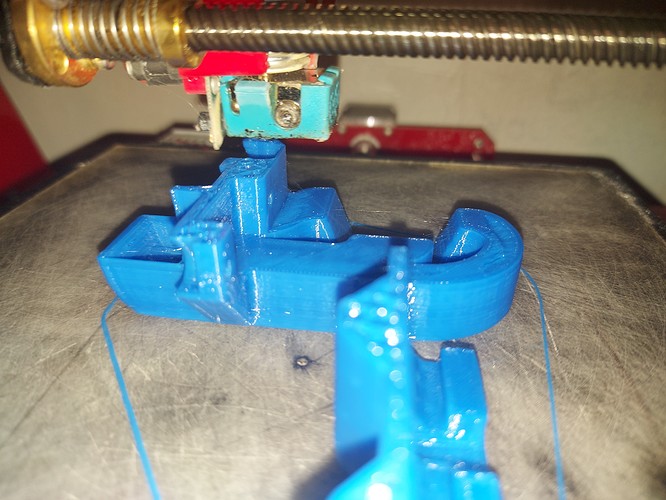

Just a tray for the SKR Pro. I also broke one of the belt tuggers, so I reprinted it.

It’s not too dissimilar from the tray that Ryan designed, with holes lined up to attach wires to. It’ll do until I can figure out more what I need.

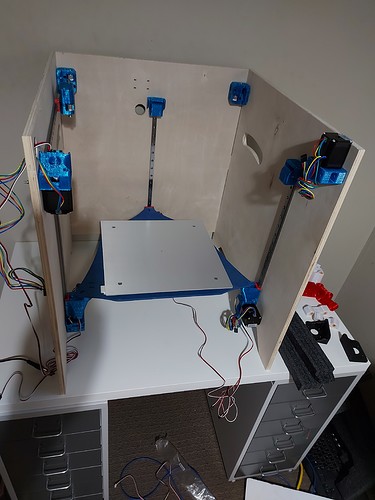

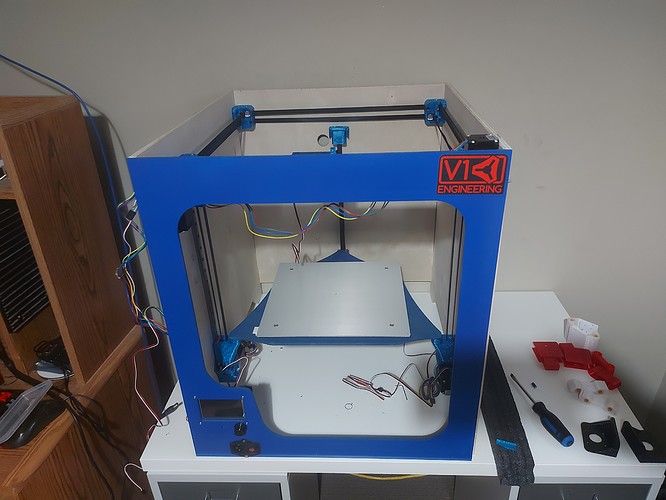

My wiring is typically kind of messy. I should do something about that. It’s been that way since I was a teenager messing with stuff, so might not change anytime soon.

So that’s the tray mounted on the side.

Looking at the wiring… gonna need to extend the wires for the Beta motor, as well as Z2 and Z3. I’ll also need another passthrough on the left panel for the LCD and the Z motor wires.

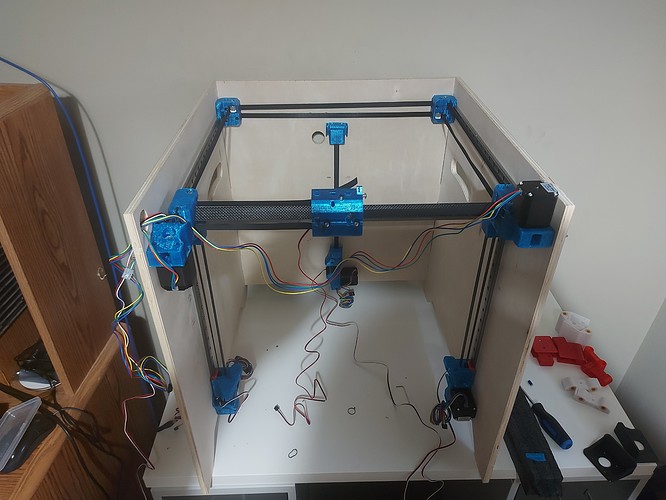

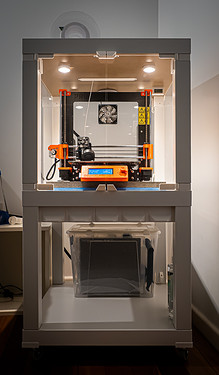

I put a couple of LED strips inside the front panel. They’re 12V, but I can either put them in series, or use a buck converter to drop the voltage. I tried the series trick with my old printer, it worked, but the LEDs got dim after a year. Maybe because cheap Chinese LEDs, maybe because of the series trick. I think I’ll use a dimmer circuit, which will allow me to save the LEDs lifespan, or just turn them off. It does require the buck converter, but… I have one.

I need some M4 screws for the PSU, too.

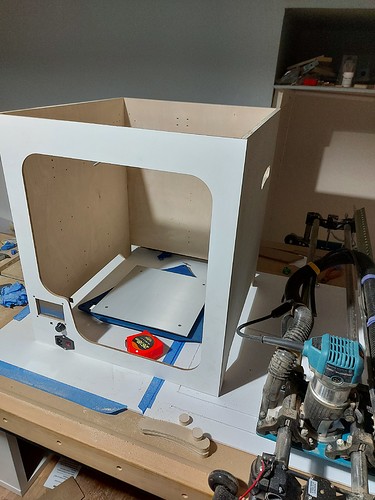

The hold-down screws for the build plate are a little short at 30mm. I think I need longer ones. The screw heads also are a trifle small for the springs, they can pop through if I tighten too much. I guess washers might be called for, too.

One of the supports for the build plate sticks out just a little too far, and it interferes with the hood over the belt pulley. (The one at the back center) I hope that I don’t have to raise the bed height more than that. Well, I suppose that I have a few mm that I can release tension on the bed springs, so I can most certainly get there.

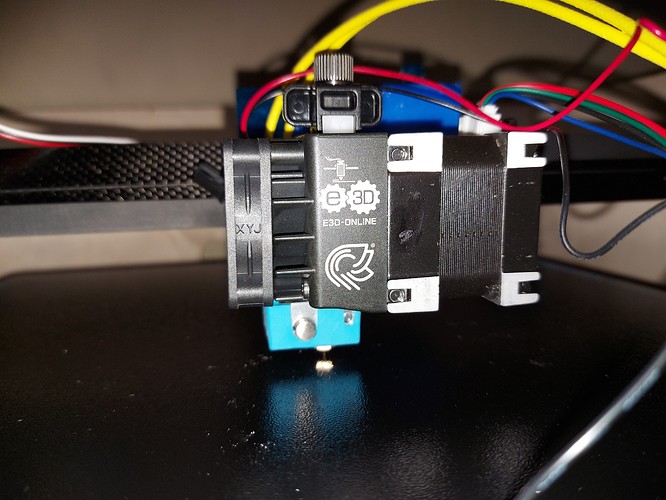

I really should have realized that I was going to need the extra pass through. Also, it’s almost 99% sure that the umbilical for the print head will come out the top of the left side, instead of the back where I left the provision for it. If I move it tot he left hand side directly above the board, I will not need any extenstion for the Hemera or the X endstop whereas I most certainly will need to extend all of that wiring if I do it at the back. If I do keep it at the back, I’ll make up a PCB to connect all the wiring to, and make up an extension harness, but really, I don’t see the need.

I left a few inches of belt sticking out the back of the belt tuggers, but I can see that these might interfere when the printer is close to Y_MAX, so I’ll trim them as soon as I have the machine guaranteed square and the belt tension adjusted to my liking.

at that point it should be able to start up.

at that point it should be able to start up.