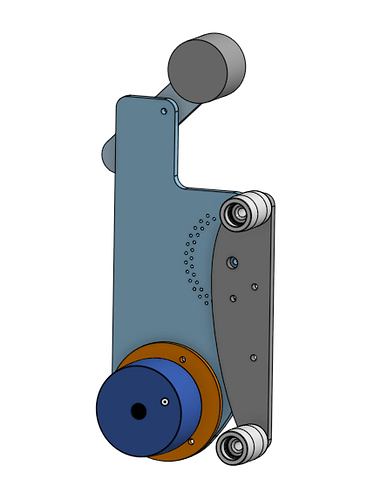

About 2 years ago I designed a belt grinder attachment for my bench grinder which used an 8 inch contact/drive wheel and built it using 1/4" steel plates from send cut send.

It’s worked well and met the design goal of allowing me to use the same woodturning tool sharpening jigs that I use on the other grinding wheel. It’s allowed me to change grits quickly and grind stuff that I don’t want to mess up my nice CBN wheel.

But after using it a while I’ve decided that the surface speed of the belt is just too high. So I’ve designed a modification to change out the 8 inch wheel for a 4 inch one with an improved flat platen.

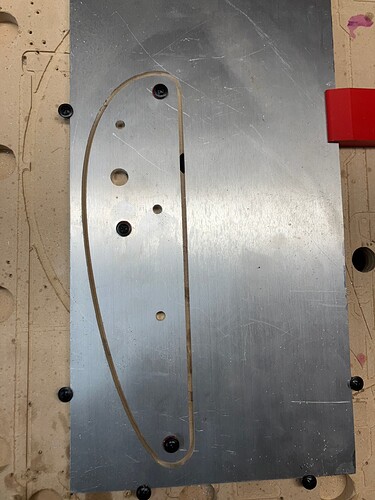

So I motivated myself to finally attempt aluminum milling. I was surprised how easy it was. At first I did some tests following this excellent guide by Mike. But I was interested in trying regular milling instead of trochoidal. Here are the parameters I ended up running:

bit: 1/8, 3 flute

rpm: 24k

feed: 30mm/s

doc: 0.01"/0.254mm

I first bored the holes then added screws to hold down the inner section, then milled the profile. The total job took just under 30 minutes. It worked really well and I think I could increase the depth of cut or feed rate a fair amount. I think I’ll test 0.02" and 0.03" depth of cut since the cutting force was only about 2lbs/0.9kg. And I have it in my head 8-10lbs is possible for the LR4?

Anyway here’s a video of the job.