I guess it is better late than never to make a quick build log regarding my LR3. My V1E journey began with an MPCNC. Build Here. I used it for a month or so, then decided to switch to a LR3 mainly for its form factor.

I first built my LR3 on a standard 4x8 sheet of plywood, with the intention of it doubling as a workbench when the lowrider wasn’t being used.

It worked very well and I made several projects on it, however I quickly discovered I had no need for such a large machine, and it took up way to much space. Another big issue I had was

noise. I generally am cutting hardwoods like white oak, walnut, maple, etc. and while the lowrider was bearable when cutting things like mdf, it was much too loud when working with

hardwoods. I live in a small apartment with an attached garage, and while I have been much louder with other woodworking tools and have not gotten any complaints, I wanted to be

able to use my LR3 without having to worry every time about the constant sound.

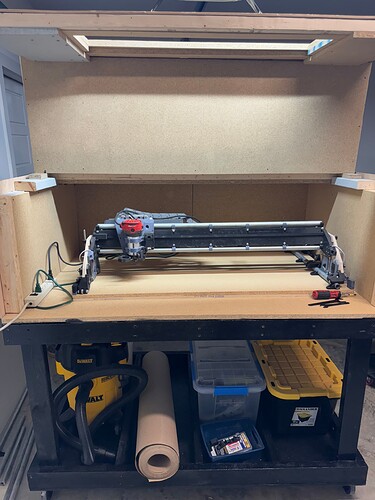

This led me to the next phase of my LR3: An enclosure. I have only seen a couple of LR3s enclosure builds on this forum so far. Most of my research/inspiration came from looking diy enclosures from other cnc machines (shapeoko, onefinity, etc.). The absolute number 1 goal of the enclosure was too keep the noise down. Dust management was a nice bonus, but sound deadening/isolation was key.

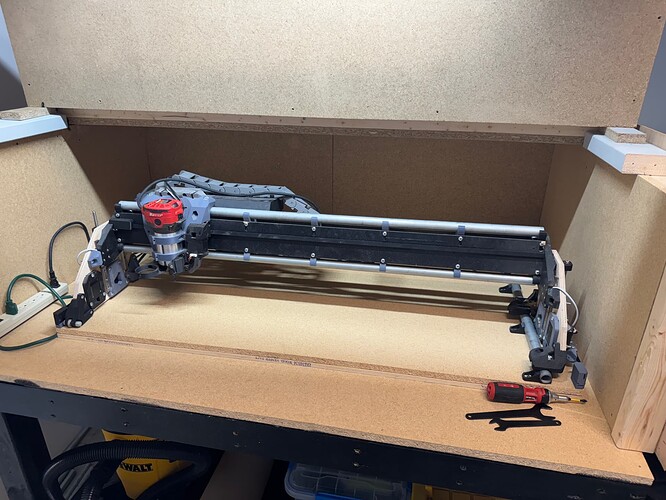

The enclosure mainly consists of particle board, 2x2/2x4s, and 1/4 plywood. It is essentially your standard framing, with particle board on the inside and the plywood on the outside. I probably could have stuffed some rockwool/insulation material in between the studs in the walls, however I wasn’t sure what the best material would be and how effective it is in regards to cutting down sound. I wanted to make sure I had plenty of room to access my work area, so the entire front face and top half hinge in the middle, so that I can reach all the way to the back pretty easy. Right now my LR3 is just sitting on two more pieces of plywood, as right as I started building my enclosure I discovered that the LR4 was on its way, and I somewhat lost motivation to perfect my LR3 since I know I will be building a LR4 the second it comes out.

In terms of sound isolation, this enclosure does great. I have only done several test cuts with it, however, when fully closed, my 20x20 box fan on speed 3 is louder than the cutting. When I step on the other side of the garage wall, it sounds about like the A/C running in a house. Overall I am very pleased in that regard. On a side note, the dewalt vacuum pictured is the “stealthsonic” vacuum, and it is 100x quieter than any other shop vac I have used, highly recommend.

There are two big things left, and I wanted to get some more opinions regarding them. Firstly, is there some type of foam/rubber insulating material that I could rest the plywood the LR3 is on on top of such that the vibration/resonance wouldn’t carry through into the rest of the enclosure? this was very much apparent on my 4x8ft build, and I think heavily contributed to the overall noise. Secondly, I haven’t decided on a good way to route power/vacuum hose into the enclosure without just cutting out a hole and letting all the sound out, so any recommendations are welcome!

I want to thank Ryan and all of V1E for such an amazing machine, and I can’t wait to put a LR4 in this thing!