This is the most important part. If you don’t know it is probably too fast and the arduino will just ignore it. You must find this number. I do not own the software so I have no way to help find it. Meaning it will go down fine at 3mm, but not come back up.

Here’s my material setup… I’ll see if I can find anything else. As I said, I didn’t have any issues until I used the newer one. I’ll probably do a dry run later today using my original postprocessor.

Those are not speeds.

Test 5 should work.

Really though estlcam is much easier to use. It will really help you understand the most important settings.

I didn’t have that issue until I used Test5, though, which is why I’m hesitant to use it again. I’ve been using the same file in Aspire since the beginning and the only difference was the post-processor.

For the rapid Z plunge rate, according to the Aspire site, “By default, the Plunge gap is set to the same value as the Clearance gap, which means that there will be no rapid plunges.” I have my base plunge set at 3mm/s, which shouldn’t be changing.

Would the rapid rate reverse the Z-axis? That was the main issue I saw: instead of raising to 3mm above the material, it plunged.

Zip and post your gcode, I can tell you exactly what is happening with your speeds.

Plunge rates are down into the material, rapids are out of it in the Z. XY rapids are all non cutting moves. Most all programs link the XYand Z rapids. We un-link them because we use different gear ratios.

The speed for plunge is in the tool selection menu, near the top when you’re adding/editing the toolpath, and using edit will let you alter the value for that specific cut. Please post a picture of that, instead of the material setup. I use aspire on a daily basis with my mpcnc, so I’m sure we’ll figure it out.

I’ve attached a photo if you need help finding it, ignore the feed rates for x/y, it’s for another machine.

Yeah, my rates aren’t really any different, other than a significantly smaller pass depth and feed rate.

Here’s what mine are set at:

If at any point that tries to move the Z at 20mm/sec it’ll fail with those types of symptoms.

It never tried to move 20mm/s on the Z… but I think it did move the Z 20mm in the wrong direction.

Applied to all Gcodes post process with Notepad++ to manually add a G0 feed rate, quick hack, but I can use firmware with stock documented adjustments. Used the rest of this thread to set up tool path speeds.

[attachment file=“2019-03-22 21_50_58-Replace.png”]

X axis

Find What: G0X

Repalce with:G0F508\nG0X <----508mm/min

Z axis

Find What: G0Z

Repalce with:G0F50\nG0Z <----50mm/min

There is something with the way rapid feed rates is handled in the firmware and the way Aspire outputs commands between paths. I dont care enough to solve it but this hack works to get me working paths. Once solved Aspire becomes a pretty reasonable workflow for many existing trained CNC operators. 4

Is there a file for inches or just mm?

Is there a post processor for vectric that uses inches or just mm?

in reply to Klaus’s “Marlin_mm” upload file …

For those not sure what all this Post processing “PP” talk is about in terms of how and where to save the file Klaus has uploaded.

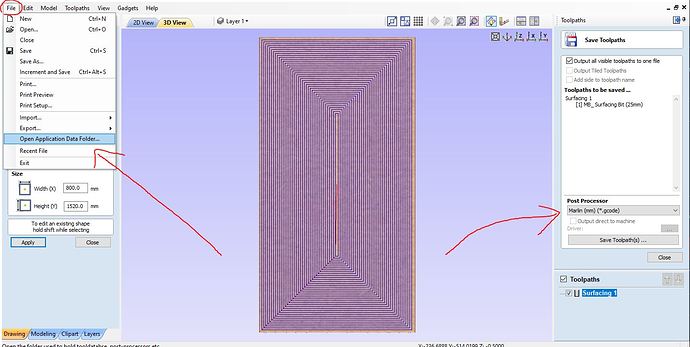

YOu need to place the file into Aspire’s “PP” folder you can find the folder within Aspire by going FILE >> OPEN APPLICATION DATA FOLDER inside this folder is the “PPost” folder where you will place Klaus’s “Marlin_mm” file

After this you will need to restart the Application for it to actually show up in post processor drop down list.

(As Per image )

HOPE THIS HELPS ( note: I used Klaus’s file as of 06/06/21 ) & it worked for me.

I know this is an old thread but has anyone come up with a post processor that allows for tool changes? Do you folks that need tool changes simply run multiple different files and then manually do a tool change between running each file?

I run aspire and do as you suggest running individual files for each bit. As long as you don’t power off your board, you just have to rezero Z between tool changes for each file. Pretty simple.

I assume that means it also leaves the steppers engaged after every run? Which post processor are you using?

I do leave the steppers engaged until the last run.

If you find it useful:

I group all toolpaths into one file, tool changes run smoothly.

You will need to make adjustments on lines 67 and 118, the value should be set to the height of your touch plate.

I also provide the equivalent for Artcam:

In this case, the lines to be modified shall be 63 and 97.

Regards

Roger