I don’t have a chop saw, so getting the conduit cut perfectly is a bit of a challenge. I’m printing off some legs now, but I’m just wondering if anyone has ever tried this before.

Cant say I have seen anyone try printing the legs. May work.

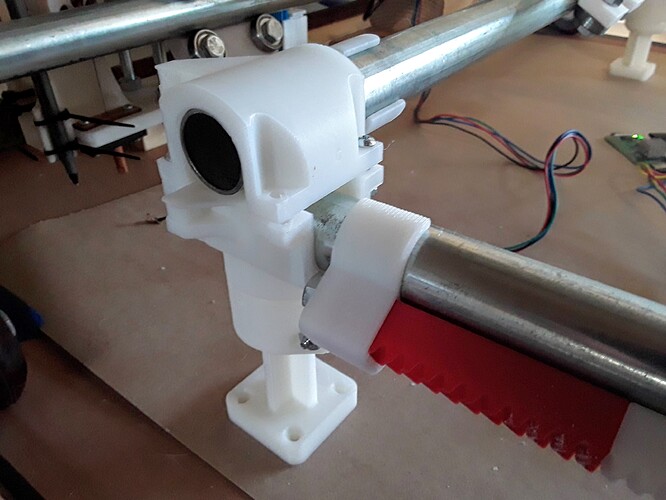

This is what I use to cut the conduit… Works really well and gives a nice straight cut

I use that same cutter.

I ended up adding lccktite to the screw under the red cap (inside the handle)- it kept working loose and falling off. Otherwise, that tool works great.

Thankfully I haven’t had any issues so far. I bought this one during the LR4 beta when I was getting some 1" EMT and it has worked great for all my builds so far. I will check that screw and add locktite. Thanks for the heads up

Cutting tubing is hard and I hear you! Hacksaw or cheap cutter from harbor freight is how I’ve done it. The rigidity of the steel is essential though.

As an alternate solution, create 3D printed spacers that clip to the legs between the foot and the head of the leg to standardize the height.

I use this system but take it a step further. I drilled holes below the tubing for each leg, made my legs longer, and have three sets of spacers at different heights. This allows me to keep my Z height low for most milling, but allows me to jack the height up for things like 2" foam.

I’ve done the same thing with my MPCNC @robertbu. I change the height depending on what I am trying to fit under my laser.