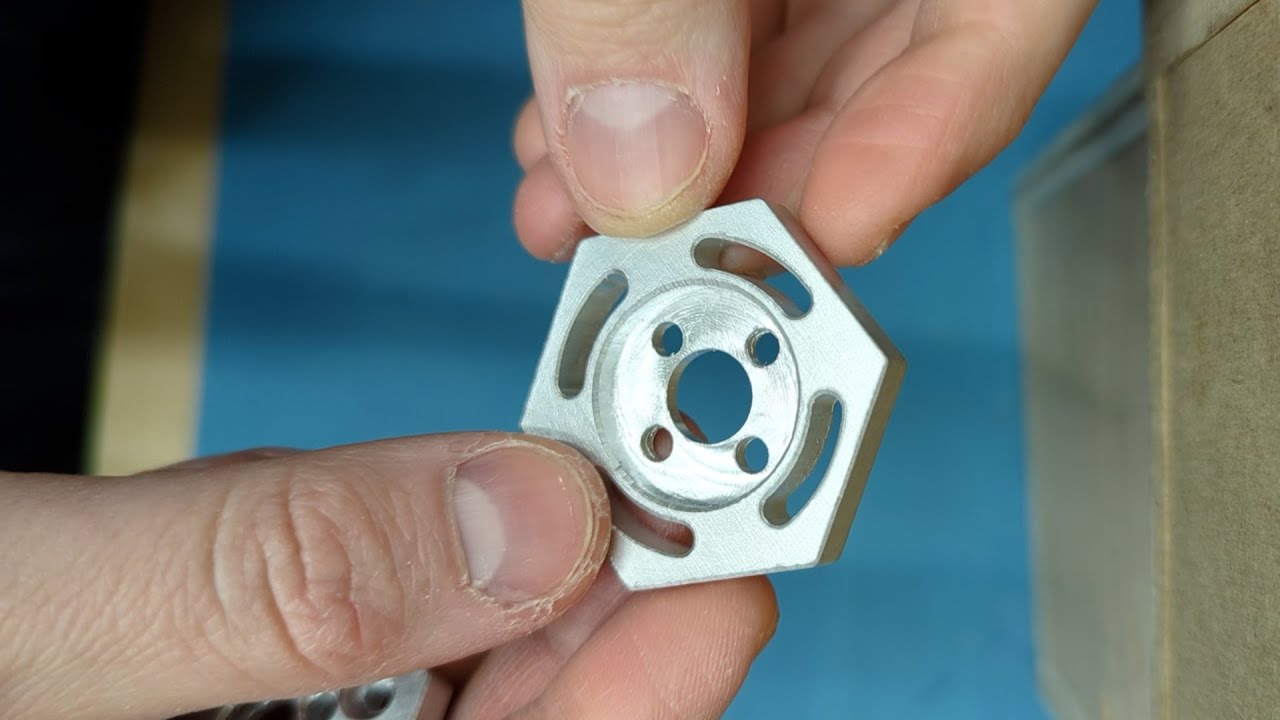

With all my recent upgrades to my MPCNC (video coming soon), I just tried another aluminum part and it was a very satisfying outcome. I’m feeling very good about aluminum now!

- Op 1: 1/4" (6.35mm) single flute carbide adaptive clearing, 22k RPM, 4.0mm DOC, 600 mm/min, 0.6mm load (trochoidal stepover)

- Op2a: 1/8" (3.175mm) single flute carbide adaptive clearing, 26k RPM, 3.0mm DOC, 500 mm/min, 0.3mm load

- Op2b: 1/8" (3.175mm) contour/profile, 26k RPM, 0.4mm DOC, 500 mm/min

- Op3: 2mm single-flute carbide, bore holes, 26k RPM, ramp 200 mm/min

- Op4: 1/2" V-bit (45deg) two-flute HSS, 14k RPM, 0.5mm chamfer width, 1.0mm tip offset below edge (this operation was a bit rough, probably should’ve had tip offset lower, so the contact edge of the V-bit would be higher and have higher surface speed)

I don’t have a clip of the adaptive/trochoidal for this part, but here’s a clip for an XYZ plate I milled, same settings. Not the biggest chips, but it’s certainly not dust.

- https://photos.app.goo.gl/SRV2B4LyAtVKdQRSA (NOISE WARNING)