NO squaring…  … yet

… yet

Ok, again life, study, boat projects and its seems EVERYBODY want some of my time, so i have not been able to get much progress on the LR3.

But with the public Holiday in Aus, i was finally able to get back and finish up the LR3.

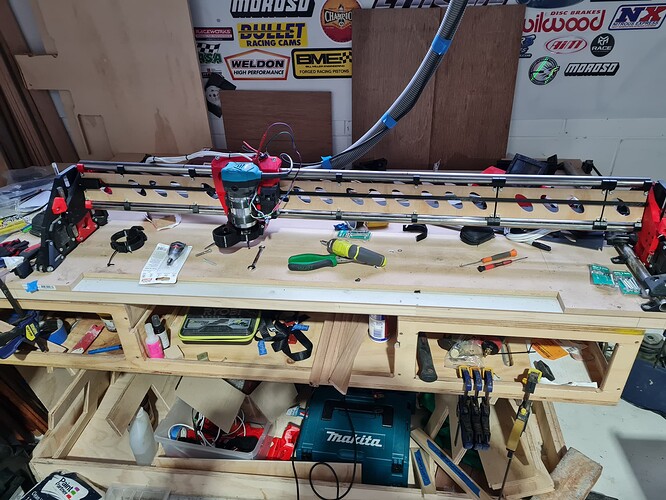

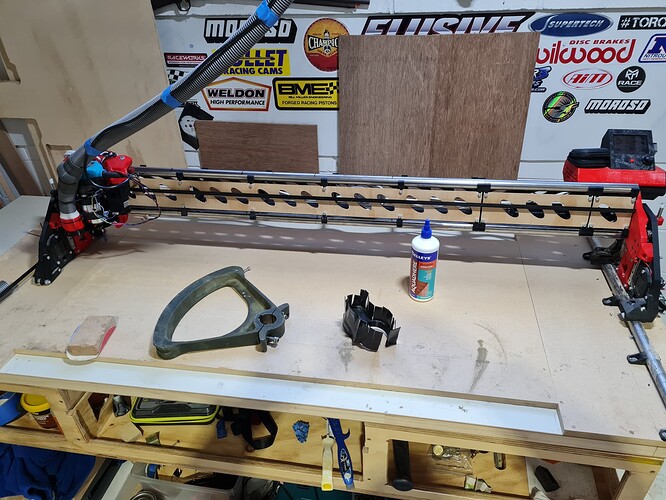

So i got the last little bits cleaned up, bolts in, wires cable tied and even had a brain fart and figured out a cheap and hopefully effective dust skirt.

I am using some Cloth Tape “gorilla grip external” tape folded over and stuck to the outside of the removable dust shoe. i then slit it several time and made the little fingers. they are stiff and if the router grabs one, hopefully they will just get chewed off. (not ripped off.) I am using the Magnet mode for the dust shoe.

I also fixed the vac system, re running the vac tube a little and trimming the length etc. Oh and i added one of my 3d printed ball joints. this is probably the first serious part i printed years ago and its still going. It works pretty well to relieve the stress of the tube not turning etc. Ok, it leaks a bit but i does “suck down” and closes up, but it def not perfect.

I would like to have one of those quick CAM release units on the top of the unit so i can remove the vac hose to clean up the table.

But with no printer and having to beg for time on other peoples printers, beggers cant be choosy. lol

(@bitingmidge MMMMM Voron2.4…)

Jobs still to do:

square the LR3, need to read up on that.

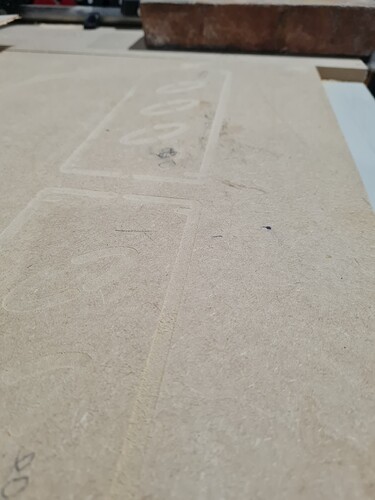

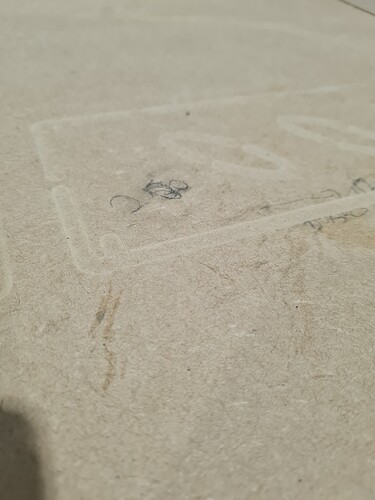

surface the spoil board

Some sort of hold down system

CNC Jobs in the queue:

New pedestal base for the boat.

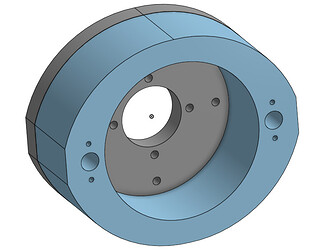

These big sheaves (pulleys for you land lubbers)

Need to be inside that block of wood. (basically that lighter circle in the picture is the size of the base of the Sheave plate. The Sheaves redirect the steering cables) so the block is like this

So it will be cut out of either Teak or Tasmanian Oak 18mm thick finger joined table tops.

(then slathered in penetrating epoxy and then varnish of some sort, maybe Epiphanes)

This one i am still note sure about, the LR3 could do it as its just bronze, Tassie oak is probably harder than it, For those that have not seen the other question on how you you would machines this, i need to enlarge the hole from 38mm to 45. But its a one off component that would be very hard to replace.

The local loan shark would get a lot of business from me to pay a machinist around AU$500 to line bore it.

The damm list is growing with signage for my brother, little lables out of that dual layer signage board for the boat systems, and engraving in aluminium (paid work, woo hoo)

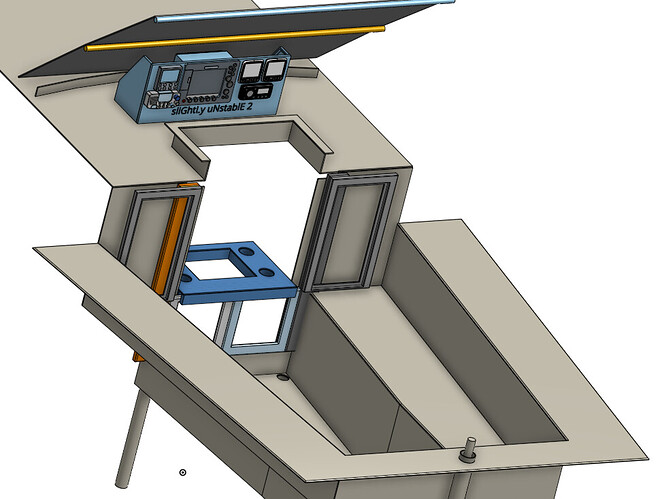

Edit: forgot that i have to make a new box to hold all the boat chartplotter and various readouts.

Was going to look like this:

and sit here

Yes i modled the cockpit of the boat, and yes it to scale.

Also yes the boats name is “slightly unstable 2”

But with the pedestal that has changed and its going on the pedestal.

More work in can LOL.

Well back to work.