Yea, up in spring hill.

Building a CNC using ancient technology, nice. ![]()

![]()

The M18 orbital sander sure came in handy today while the lights were out LOL

Ok I ran though and checked all the screws on the offending YXZ setup. I cant find any that have an obvious wobble to them. I moved them all around and the problem stayed exactly the same. As long as they were a touch loose everything was good. As soon as I get them tight it binds up. Last time after tightening them I loosened the screws from the XZ plate to the rails and then tightened them back but a much much less as soon as the screw stopped turning from easy pressure I stopped. And with that it rides smooth. What’s the chances I could put a dab of blue lock tite on all the screws and leave them at that point and it stay together with vibrations from milling??? Or do you have another idea for me to try out before I do that???

Not uploading, but I meant the binder. ![]()

I meant the binder.

LOL I have one for the LR3 and one for the Primo. Makes it so much easier for me. I tried using my iPad but every time I wanted to look at something I had to unlock the screen. I turned it to no shut the screen off then someone needed something and I came back to the battery dead. Just so much easier to flip though the binder step by step LOL

LOL I have one for the LR3 and one for the Primo. Makes it so much easier for me.

That was the subject of lengthy discussion with @vicious1 some time ago - nice to see the “manual” in use.

I fully understand his reason for not printing and sending one. But it was easy for me to go to the docs and hit print LOL.

I moved them all around and the problem stayed exactly the same. As long as they were a touch loose everything was good.

That seems odd. Try loosening the bearing blocks and tightening the rails, then tighten the bearing blocks back up. Also try flipping one rail over, or to the other side.

Or try tightening from the middle out.

Another stumper from JJ.

I’m in Odessa, but work in Brooksville, next to spring hill. Pretty close.

That seems odd. Try loosening the bearing blocks and tightening the rails, then tighten the bearing blocks back up. Also try flipping one rail over, or to the other side.

Or try tightening from the middle out.

All of this except for swapping the rails side to side I have tried…multiple times LOL. Will give swapping the rails a try and report back.

Another stumper from JJ.

![]() At this point you should expect it LOL

At this point you should expect it LOL

Also try flipping one rail over, or to the other side.

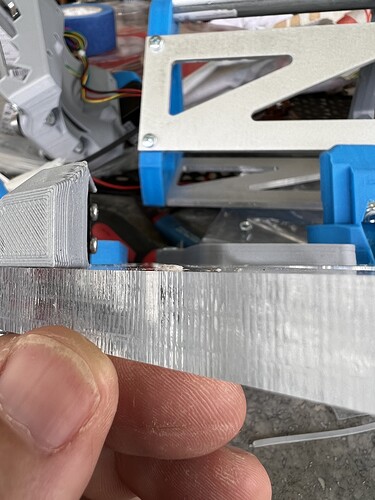

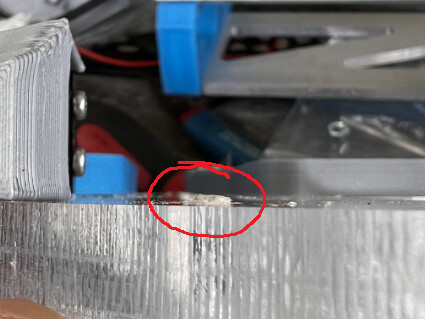

Man you always have the best ideas. Look at what I found when I removed the rails…

When I drilled the holes it was just 1/16th like into MDF. Well that wasn’t enough and I wound up having to drill them a little larger. On that top hole is where I tried it at 1/16 and it created a “bugger” at the top that I didn’t pay any attention to. Took an xacto knife and cleaned it up and now everything is tight and smooth as silk like the other side!!

It’s the little things that kill an otherwise perfect machine.

That is not an easy find, good job!

That is not an easy find, good job!

Never would have found it had you not suggested swapping the rails. Had it all apart and was setting the rail in place to screw it down and it had a wobble when i sat it in place. that told me something was in the way and upon further investigation that’s what I found. I suspect MDF would have compressed out of the way but the Acrylic not so much.

This little raised burr/bugger sitting proud of the acrylic YZ plate caused Z linear rail bind, or end-brace/gantry to wobble against XZ when moving? Must have been frustrating, good to know, cheers!

Z linear rail bind

When I lifted the plate to the top it would stick there. And be a little rough going up. Other side was butter smooth and if I let go it would fall no matter where. Now this side does the same

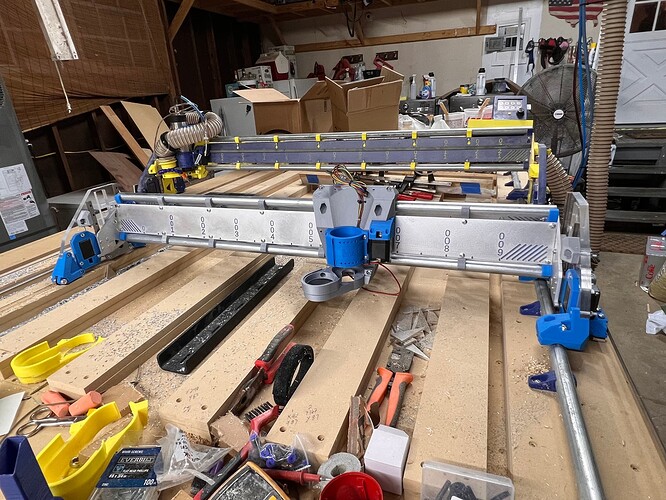

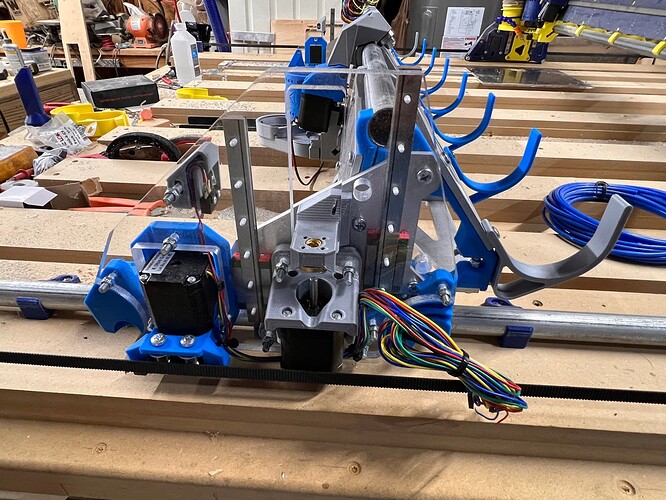

Well here is how far I made it…

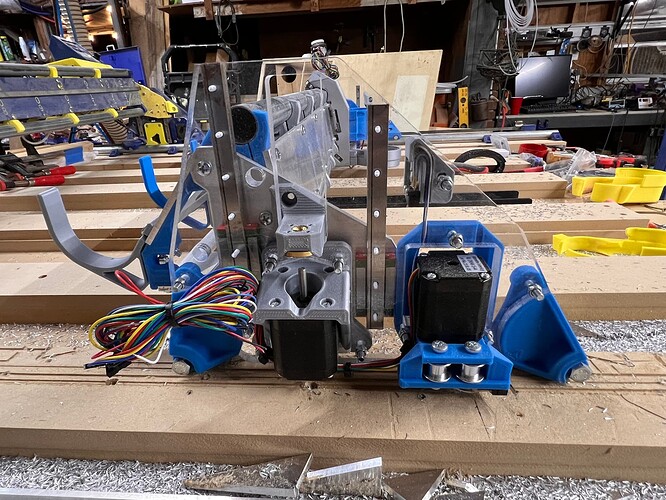

I am so very impressed with this one. The core just glides so so smooth. And the X beam is rock solid. I cant wait to see what it can do when i get it running! I already know I have to reprint the braces and probably the core for its big brother. Thinking about adding an extra brace like I did on the little one and going with the 1/4" aluminum again and see how much it stiffens up a full sheet machine.

Headed back to work at 1am in the morning so that’s it for a little while. Wont be back home until 7-19. Taking the boat from Louisiana to Rhode Island with a fuel stop in Jacksonville. If any of you live along the coast and happen to see us take some pics and post them LOL

That thing looks insane. The clear is like a CAD view I use, trippy!

Yes it is. I love it. I had the same thing on my old LR2. I have a feeling the big LR3 will get it soon as well. Haven’t been happy with the look of the 3/4 MDF and it was a royal pain to set up. All I had on hand at the time lol

That looks really cool clear. ![]()