The larger diameter emt should be a little more ridgid. I think the colors will look great!

That was my thought too but wanted to be sure. Ryan always has the engineering side of why one is better than the other.

NOOPE! Common mistake. I do not make parts to fit 25.4" EMT. Those parts fit 25.4mm OD tubing, for international uses where that is their EMT standard and In the US you can find 25.4mm OD DOM or SS tubing.

So yes there is a tiny advantage for 25.4mm vs 23.4mm OD tubing but in the US that is at a steep cost for fancy tubing.

Ok that’s good to know. I thought 1” emt was 25.4. So unless I want to spend $65 a piece plus shipping for SS tube I’m best to just stick with the 3/4” EMT. I doubt I would get a noticeable gain on a 36” wide LR3 for the cost to go up to the SS

Exactly!

I think ole USPS got their estimate wrong on this one lol. Good thing is I’m not sitting here waiting for it. Mail has already run today and it didn’t make the cut. Funny thing my informed delivery email this morning still showed it was getting delivered today

Sadly, sometimes that means it is actually on the truck and they just didn’t want to take it to your door. At least that is what my mail person told me.

Ours wont get out of the truck for anything. They just leave a slip and we have to go pick it up. But about a year ago I bought the biggest mail box I could find and that put a stop to a lot of that. But sadly no slip and no package. Hopefully its not lost somewhere in the great unknown between you and me lol.

I ordered some zigbee smart blinds from ikea. The original website said they would be here Monday. On Saturday, Ikea said it was out for delivery. When I click on the fedex tracking link, it says the blinds are still in CA, and they are scheduled for Monday.

I hate seeing bad software like this. I am sure they can fix it if they just tried for a half day.

I will say I didn’t get a V1 email saying it was out for delivery so atleast Ryan’s stuff is working right LOL

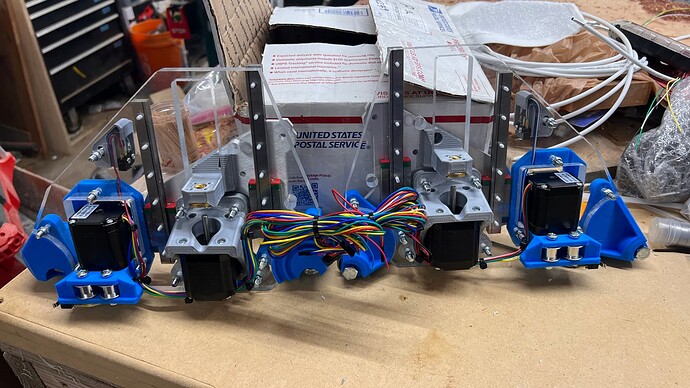

The package did come in Monday. No nice note this time… I must not be posting enough. Totally kidding! Unfortunately I had to leave at 9am Tuesday morning so haven’t touched it at all yet. Filament should be in before I get back home and hopefully the new screws for the bed on the MP3DP will be in. Then I can get it printing one color and one of my others going on another color. Still a lot of other work to do. Have to clear off a new space for the primo and make some changes to the table it’s on now to accommodate the new LR3. Should be another fun build though. Definitely looking forward to ti!

Parts are a printing. About to start the addition to the table. Currently its at 48x48 and it needs to go to 48x75 for a 36x60 inch LR3. Hopefully will be moving the Primo soon and getting the laser set up on it. Excited to have a second smaller and hopefully more ridged LR3 to use!

Also i got gipped for my birthday on the points LOL

???

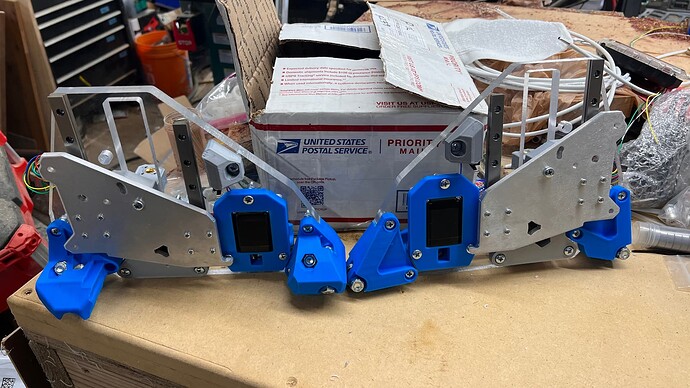

Made a little headway today. Work is messing me around on when I will leave so figured why not put some stuff together. Got the YZ/XZ plates all situatied. Well except the lead screw. Getting a little closer!

When you do put the screws on that is a good time to get the smoothness dialed in. Make sure the stubs are straight, the top of the screw doesn’t move in or out all the way at the bottom. Set the couple so it is slightly stretched, allows for full range of motion and only have a couple mm of stretch if you over drive the bottom.

I have one side that the rails are butter smooth. The other binds slightly at the top. It’s not by much but enough that the aluminum won’t drop on its own. I have messed with it and messed with it. Loosed it all back up. Slowly tightened everything a touch here and there constantly moving it around and as soon as I get the ends of the rails tight the exact same binding is back. Like I said it’s not much at all. If memory serves me correctly I had the same thing on my first LR3 and it’s doing fine lol. Any thoughts on how to get it better before I progress on with the build?

Fiddling with the V4 now so that I can hopefully get some more parts printed. But I’m going to have to print 2 new parts for it first I think. (Making a post in my build thread for it next). Got one of my other printers printing some braces now and my daughter is bringing home some 3/4 EMT this evening so hopefully I’ll be putting the x beam together soon

About the sticking at the top:

I had the same problem and I found that the X-belt stub (loop) was hitting the Y-X plate at the top. I shortened the loop and that problem went away.

Mike B.

Thanks for that but I don’t think that’s my issue at this point. I don’t have any belts installed yet. This is something with the rails I believe. I will definitely watch out for that when I do install the belts though!

Also forgot to mention I picked up a piece of aluminum today to cut the struts out of. Hope to be cutting them later today or tomorrow on the Full Sheet LR3 (Fat Albert as the family calls it). Going to try to take a few videos and post them when I do.

@vicious1 Now that I have the air blower thingy I seem to remember it being said to mist IPA when cutting aluminum. Do you (or anyone else) know what PSI you are running your air at for that? My air line hits an inline regulator to bring down the garage air from 100psi to whatever I need, I think I have been running about 25psi for the acrylic cutting. Also about how much IPA I need to have on hand to cut 3 43"ish struts?? Just wanting to make sure I’m ready to go. Hoping for a real good finish on this one. Going to dig up my old thread when I cut the bed plate out for the V4 and see what settings I used. I wasn’t running air or IPA then and it came out REAL clean. Hoping for the same result or even better this go around.