I don’t remember exactly. Wasn’t too bad though. I was looking at the timing to cut out a 1450mm one for my full sheet machine last night and without the windows just the holes and cut it out it was 1.5 hrs. estimated

Those pens are picky. Smooth paper, light pressure, and you can’t draw too fast…or they die.

Oh, that does not sound too bad. I’d need to flip them again because my machine isn’t big enough, but I am really contemplating it. Even better would be CFK, but I like to live and I like my money. ![]()

Can you get it at an angle??? Be a pain to set up but still better than flipping and lining up again

Yeah…they do awesome on paper…MDF not so much LOL. That first line was great…then it just died. I tried running paper under it between lines and that worked on the first one but not after that. That’s why I switched back to the felt tip.

The thicker lines are a natural reminder that tolerance is a thing. If you need more accuracy than the felt tip can give you, you should probably be using something other than the pen lines to line it up.

I would use that ruler on every job, just to gauge where to put the material to make sure I had enough room. Seems very useful. For that use case, I would probably only mark every 5mm or so. If it needed more precision than that, I would probably want to use the machine to measure it out.

This wasnt at all for accuracy or for the true need to line it up. This was strictly because I could lol.

First actual cut on the new LR3. Bottom panel for my V4 out of some old 1/4” plywood my dad had. Going to spray paint it black before installing

From the best I can tell I might be about .5mm out of square. But I don’t think that’s the case. That short didn’t come out quite as round as the others. That was the start/stop point.

Hey, just found your channel and subscribed! Thumbs up on your cool new LowRider V3 and your Mostly Printed 3D Printer V4!

( Says me about 15 minutes after you already replied over on YouTube! ) ![]()

That looks like your answer right there.

One thing to be sure…Check the thickness of your aluminum when you buy it. Turns out the sheet I got for the little LR3 was 3/16" not 1/4" (my bad @vicious1 ) but still was strong enough to make it where I cant flex it at all. This sheet I got for this next set is true 1/4" so at 1450 mm it should be good LOL. Now I just have to cut the sheet down so it will fit on the new 3x5 LR3

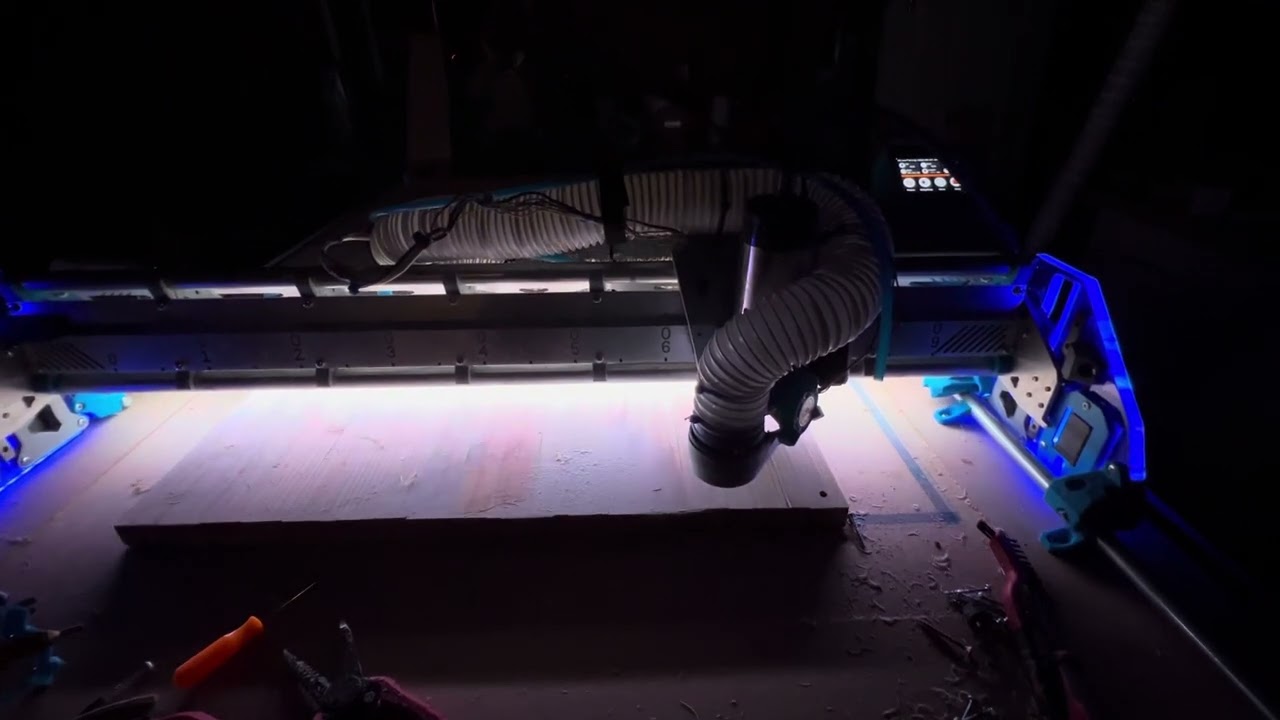

Doing a little surfacing. Guess I stood still too long and the motion sensing lights turned off. But I could still see the cut lol

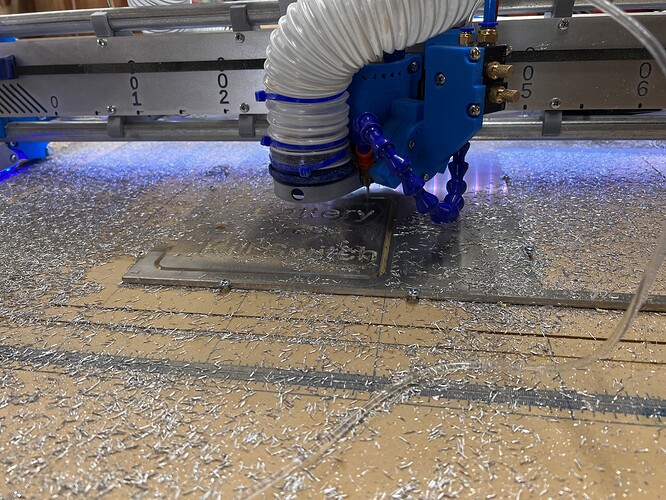

Use the vacuum! You are making me mad with chips in the bearings. ![]() How’s that car supposed to look?

How’s that car supposed to look?

Im sorry to hurt your poor little feelings @Tokoloshe… LOL Seems counter active to use the vacuum one direction then blow air/IPA the other lol. But i did go back and vacuum after this pic if that makes you feel better.

Will post some pics of the car in a few. They are out there working on it under the shade tree.

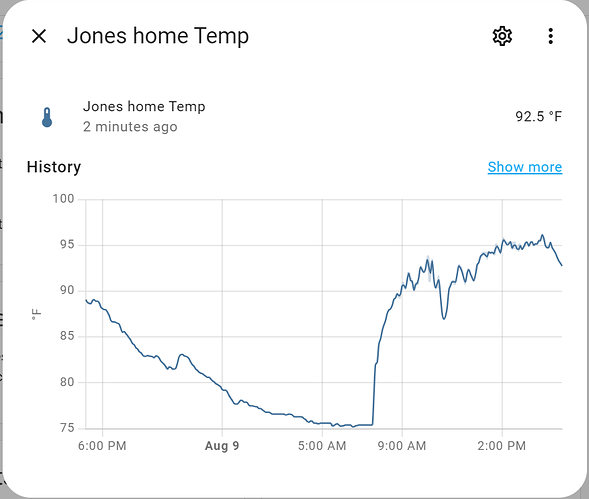

Its hot here in Florida today LOL

Uff, 42°C…

Louisiana….it’s been the same here

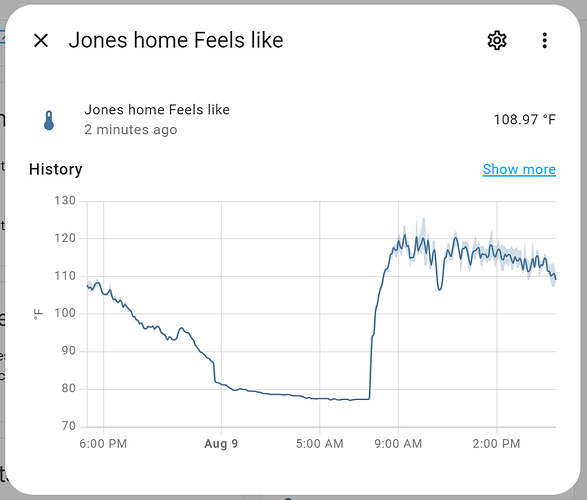

This is what it’s like in my shop when I get home

“Feels like” 115 in there

I believe it! I usually work out of Louisiana offshore and it’s brutal. Luckily we are now in the north east for a little while. Headed back next week and already looking forward to the weather difference lol

We’ve had 18°C here… My shop usually keeps the same temperature, no windows towards the sun, a flat on top of it…

Uff 64.4° F