Neat! Was great to see Cameron’s latest design at Open Sauce 2024 a few months ago…

Look forward to seeing updates …

Can I be a beta tester? I love the idea and I really wish to build it.

Guess who finally made it… @camchaney.

Welcome to your section homie!

Wooo glad to be here! Thanks @vicious1 for getting this category set up

Totally! I’m working on getting the BOM and instructions together right now. I’ll put that all in the GitHub repo and publish sometime next week. Will do another post once that is all ready

Any pictures or clips of the current status of your build? You progress so much so fast, it would be cool to get some sort of status updates as you try things out.

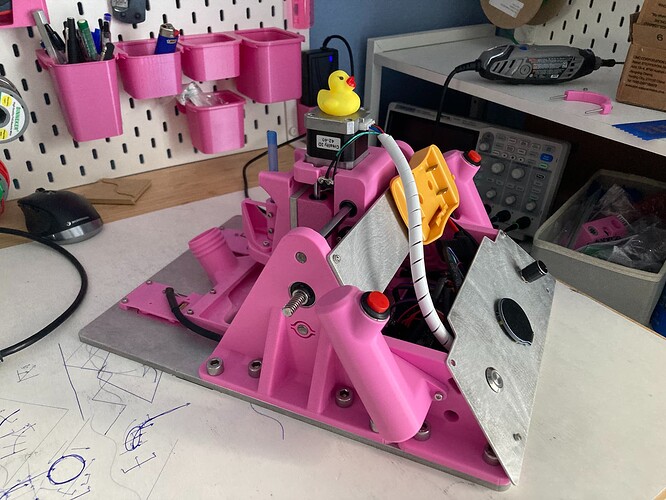

Totally! Here’s what she’s looking like right now (still rocking the ducky from Open Sauce):

Been doing a bit of testing with wood and MDF, trying to improve the dust shoe design and make sure the sensors are staying resilient. Definitely want to start doing some more testing, though, to really put it through the ringer.

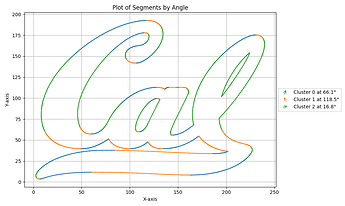

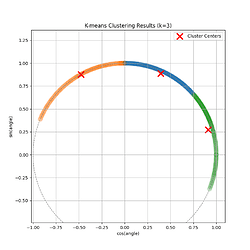

Also working on a path planning algorithm to make more complex designs possible. This takes a gCode file as an input and segments the design into multiple passes to minimize the amount of user input needed. Cool little visuals from that:

From those of you who saw the device at Open Sauce, there are now new motherboard and sensor PCBs which allows the sensors to be connected with JST SH connectors. Unfortunately, though, I was having trouble getting my hand crimped cables to work well with the finicky SPI communication, so for now the sensors are just soldered onto my board. Talking with a cable manufacturer atm to get some better ones made.

Also, as you may notice, I’ve attached a power tool battery adapter so we can now go cordless!

Will keep updating as I go, so stay tuned. Planning on kicking up a lot of dust in the near future…

Did you do the metal plates out of necessity, or do you think it can be more 3D printed further down the line?

Both seem like a tough call. Laser cut metal is super cheap in bulk, but one off’s are very expensive.

I’ve actually been thinking about ways to eliminate them recently. I think the faceplate, the crossbeam, and the metal plate for the z carriage can all be redesigned pretty easily for 3D printed parts. I made these all out metal initially simply because I could hahah, and I didn’t really have to think much about it. My makerspace had a metal laser cutter and a lot of scrap metal.

The baseplate, though, offers a lot of stiffness and would be a bit trickier to replace. I’ve thought about doing a 3D printed part that’s reinforced with metal beams, but am still workshopping that. Open to ideas! Also as you said Ryan, laser cut metal would be super cheap in bulk, so if there’s enough interest I might just do that.

When you get to the beta test stage, it will really help lower the bar for users if they can just 3D print it. Even if it is not ideal. Probably fewer fasteners as well.

I used to shy away from larger prints, but large monolithic parts are extremely rigid, and can be very accurate. Now, printers are so much faster, it is only a half a day print to do huge parts.

Super valid point. I will add that to the to-do list.

I just saw an email with that Github repo. Will let you share when ready. ![]()

Yuppp, you beat me to it hahah ![]()

Just made another post to share the repo, but here it is again:

Hey @otiliaGen, Thanks for the compliments!

The firmware is completely custom. I’ve thought about merging into grblHAL, but that’s more long term.