I’m wondering if homing current is just a FluidNC thing? Like it’s just using that config value for the run current while homing?

Also, I don’t really know what I’m talking about here beyond what settings exist in my Jackpot config.

I’m wondering if homing current is just a FluidNC thing? Like it’s just using that config value for the run current while homing?

Also, I don’t really know what I’m talking about here beyond what settings exist in my Jackpot config.

It is. they switch the run current out if the movement is a homing operation.

I’m digging through the Marlin documentation as we speak (well, type). This question has twigged my interest…

There is a Homing Current setting in Configuration_adv.h, but it seems to be for sensorless homing (the amount of current needed to indicate that the carriage has hit the physical endstops to indicate that it has reached its travel limit, I think). This is set to the same as the RUN current in the V1E LR3 SKR config.

There is also a HOLD_MULTIPLIER setting (disabled by default and in the V1E config) that can set the Hold current to a percentage of the RUN current.

So the answer to my earlier question is that those settings are available, but it appears that they were never used in the V1E configs, so the MAX-Current or M906 set values would control all three settings (or at least I interpret it that way)

That graphic refers to Hold current (not homing). Marlin also seems to have Hold current (also expressed as a fraction of Run current), but was unused by V1E.

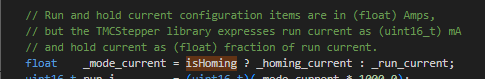

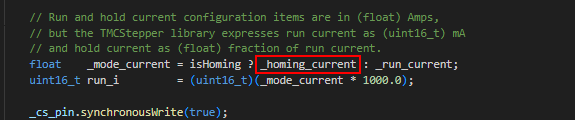

no, it’s the homing_current…

That line means, if we are currently homing, use the _homing_current, else use the _run_current

Just for reference, this was only recently added in 3.7.17

That is a feature of the TMC2209, not Marlin specifically.

It’s in Section 9 of the DataSheet as Jono linked above.

Hold Current is passed as a percentage of run current per the spec, but FluidNC lets you define it as an absolute current for convenience, then it is scaled as necessary. If you don’t set hold_current, it will use run_current

Marlin also has a homing current if you use sensorless homing, I suspect that is why fluid has it as well.

*edit, yup, thanks mike.

These are the two main steppers I have sold, the cooler one is the current (last year or so model. The right is the automation tech ones I used to sell.

They should be comparable torque at this setting. I know when had pit them against each other with a belt loop at some pint and they are tied.

The new steppers have more room to go up…but again, should absolutely not be needed. If you are skipping steps your CAM is most likely the issue, or a dull endmill.

Our Material removal rate is capped by system rigidity and always has been. We have always had larger steppers, drivers, and power supplies than we need. That is why I make new machine not just throw nema 56’s at the LR3.

Sorry, I was reading the green lines above

Is this also not for sensorless homing? (“helpful for people trying to tune stallguard homing”)

Agreed, but it has been implemented in Marlin (as well as in Fluid), which was what I was wondering

dangit…2 people…

Now I’m gonna have to buy a fancy RoboCop camera…

Yes, but sensorless homing is inaccurate and we use it on neither system.

NAh, I use it twice a year. It has paid for itself but Other than that I just let my friends borrow it to look for leaks in their house.

actually is the reason I want one ![]()

I’m not disagreeing with this statement. I’m just wondering if Homing Amps is always set to the same as Run Amps in your Fluid configs (as it is in your Marlin configs). The discussion above seemed to imply that the Jackpot would reduce the amps when homing (or perhaps I misunderstood the conversation)

Official current config from here:

run_amps: 0.800

homing_amps: 0.800

hold_amps: 0.500

The discussion above was about bringing the hold amps and the run amps closer together

The last thing I am going to do is adjust the mmpos so we are not throwing away some cutting area.

Just to be clear, when I set those number I screwed up. I assumed the holding amps were when the machine was not in motion. Fluid by default boots engaged, so I assumed (incorrectly) holding amps was literally just to hold the current position. Homing current was added later.

If it helps, I had a Fluke Ti400 at home for a while when I was working from home. It was fun to play around with but I actually didn’t find it all that useful and probably only got an hour or two of use out of it. The most interesting thing, ultimately, was looking at the heating pattern that my Bosch induction hob makes in the pans I have and now I know to compensate for the different thermal gradients over the surface of my cast iron pans vs the stainless steel ones.

I’ve been super keen to pick up a cheap one to have around but I’m not convinced I’d actually find it any more useful than a non-contact IR thermometer, sadly.

That’s not surprising, I was shocked by how garbage the implementation of that stand-still detection/hold current transition was in the TMC2209s. I guess it probably works well for situations where all the torque is needed for the motion control, not for resisting external forces. I guess it’d be great for a laser cutter or 3D printer, just not for a CNC router.

I just never trust the non-contact, never sure what it is reading.

In that picture I put up I have a strip of tape on both steppers. I was surprised to see it made difference.

Outside of this stuff I have no use for it. I would no buy on for personal use. Taking a picture and marking as many points as I want is very informative though. Room/surface temp, is always nice to include.

Those TMC’s have so much built in. I really would love to have coolstep fully functional, than this entire conversation would be moot. We set it super high let the steppers manage the current they need and only the current they need.