(First of all, sorry to all US guys, but I’m used to metric, is way easier to me ![]()

![]() )

)

I builded up LR2, 3, 4 and MPCNC Primo but never went deep into Steppers topic, I simply stick with default specs, but the LR4 capabilities are to a point where it’s worth spending time to learn thing about it.

I’m using “standard” 59Ncm NEMA17+TMC2209 with 24V power supply, and I always considered the 48W min power supply spec as ok without thinking why. I Realized that it comes from 12[V]*0.8[A]*5[steppers]=48W, but with 24V it has to be doubled, cause the Amps are the same.

So 24[V]*0.8[A]*5 = 96W + 20~30% safety margin = 120W.

Ok, not all the steppers are working at 0.8A at the same time, but the dimensioning have to be done considering worst conditions.

That said, using a stepper calculator I found that at 0.8A the max speed is about 25 rpm, but I can’t really understand why increasing the Amp this value is reduced, maybe someone can explain it to me.

With a 16t Pulley we have:

25[rpm]*32(mm/rotation) = 800mm/min

Than, considering 59Ncm torque applied to the 16t pulley(5,1mm radius):

59[Ncm]/0.51[cm] = ~115[N] = ~ 11.8kg of pulling force.

My conclusion is that we can have about 10kg of pulling force on X axis(the weaker) at a max speed of 800mm/s.

Increasing the pulley to a 20T(6.35mm radius and 40mm/revolution) we can raise the max speed to 1000mm/min but with a pulling force of ~9.5kg, more than the double of what we need(deformation tests have to be done in next days)

So in my opinion we can have better performances with 20T pulleys, considering that the speed we use on ply is between 1000 and 2000 mm/s.

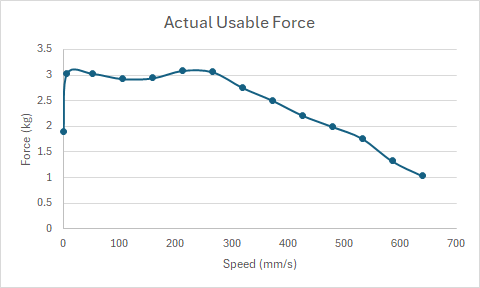

Now the missing part to me: how can we calculate the max torque at a given speed and given Amps?

Cause torque curve is made with 2.2A.