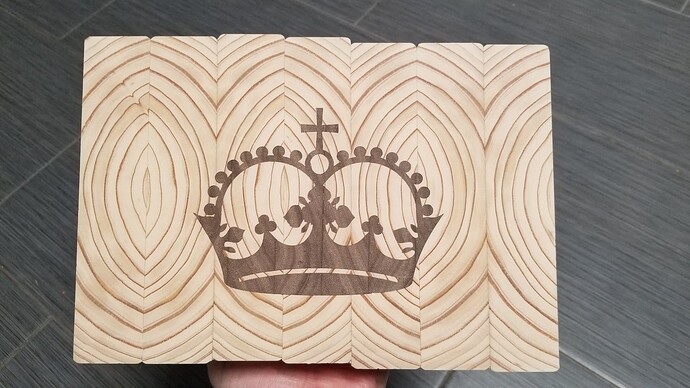

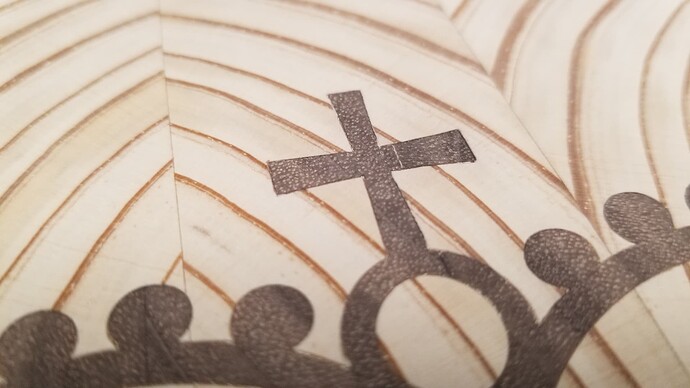

Walnut and pine this time. Used Rob’s advice and it is much easier.

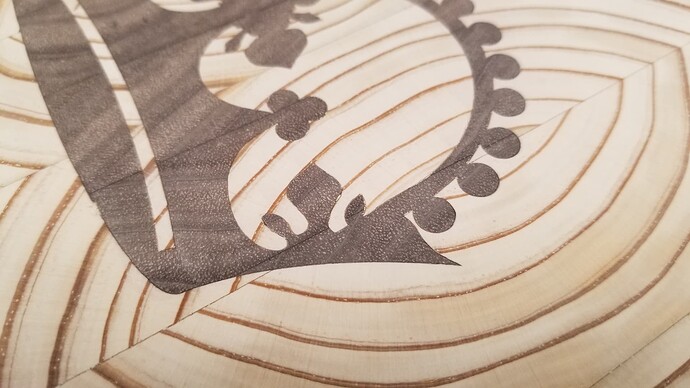

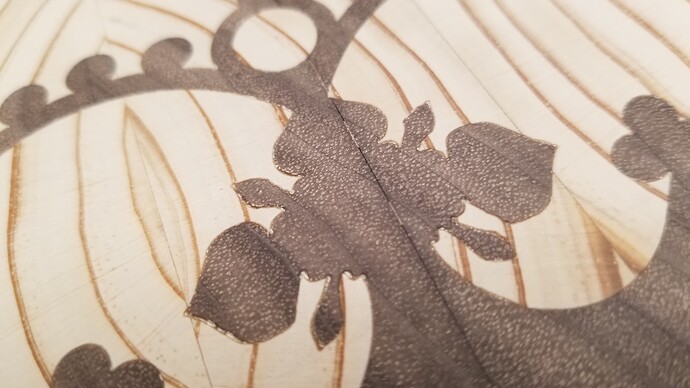

I noticed there is possibly an issue with the v-bit not being a perfect point but having instead some nonzero (effective) diameter. This makes the pocket slightly wider and the plug slightly narrower and the plug bottoms out before the sides get snug. I used sandpaper to grind down the plug until it fit snugly, and it seems to have worked.

In the future I might try to make the plug short by a bit so it fits straight away without sanding. If there are large areas, I wouldn’t want them unsupported if the plug is too short. I was thinking I could use a small bit of clay during a dry fit, and the clay will squash down to the gap size. If it is small then that’s fine, or I will know the size of spacers I would need.

Here’s some more pictures