So… This is you chasing zeros?

Seems to be a few folks that like this idea as even the $89 alternative that you mentioned & $60 JL2 alternative are now sold out on Amazon.

Congratulations! At least you found out it was posted right after the fact. I found out something I made was put on there…three years after I made it and they posted about it.

Speaking of safety. Trying to be a little safety conscious, I made this shroud for the laser. I plan on setting it so the focal point is 1/8 in from the bottom of it. That way I can adjust the height easily and still keep the gap around the bottom pretty small. I used #2 screws to attach it the laser. I found it easiest to focus it before attaching as the opening is pretty small once on.

what is the green lens you used?

I was going to ask a similar question - Does anyone know the wavelength of the stock laser? I didn’t see it in any of the paperwork, but I may have overlooked it. I was looking at purchasing safety glasses (Not sure I trust the provided glasses + handheld monocle.

I just cut up that round “monocle” thing they sent with it.

Because it is a blue laser, it should be between 400 and 450nm. It appears orange or red are the most common for that light range but green can also cover that range.

you know, just looking at the price of the cheap goggles on amazon and that monocle thing they send, and the build, 79 dollars looks better and better all the time!!

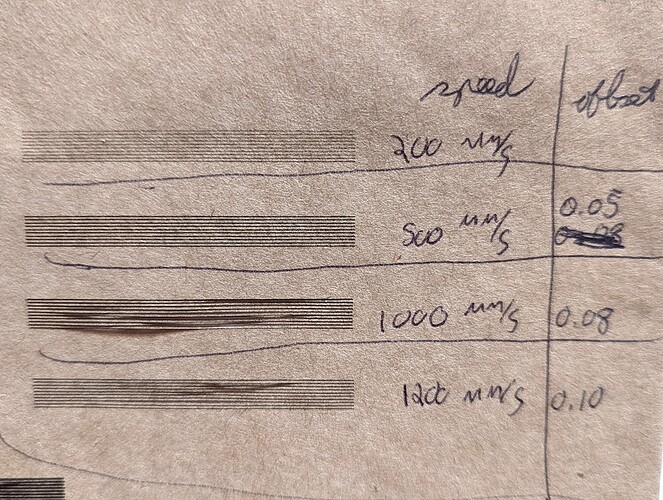

(All speed values are mm/min - not mm/s as I have handwritten)

No Offsets 1200 mm/min 50mm x 20 mm box

Played around a bit to get it close. I think I can still see a bit of room for tweaking but its pretty close to correct. 50mm x 5mm boxes

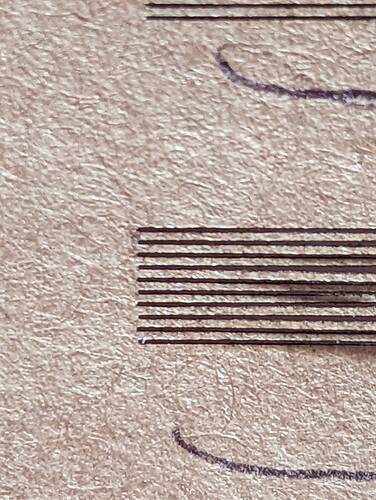

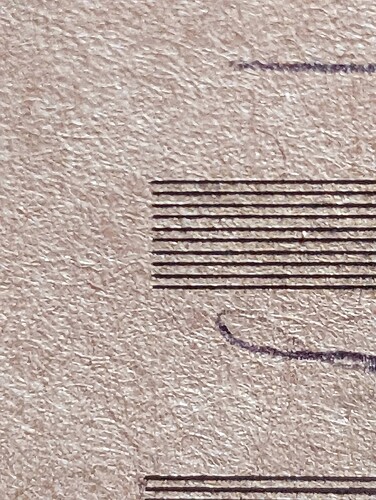

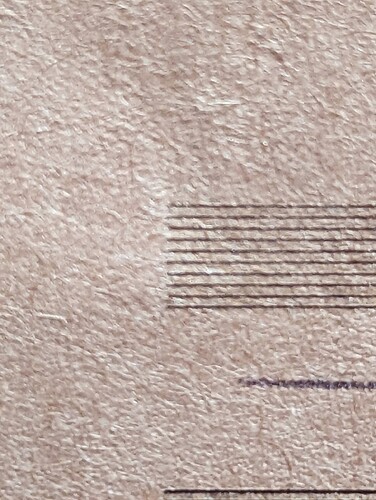

Close ups

1200mm/min 0.1 mm offset

1000mm/s 0.08 mm

500mm/min 0.05 mm

200 mm/min Lightburn autoscaled offset

I assume your values are mm/min, not mm/s. In your first picture, and the one labeled as 1000mm/s, I clearly see offsets. I do my engraving at 1920mm/min (32mm/s). Assuming these values are mm/min, not mm/s, your results are similar to what I had at 1200mm/min (20mm/s). Correcting what appeared to me to be minor offsets made a huge difference in the quality of my results…no more double lines.

You are correct, mm/min. I edited my post to say that as well.

Just a note- @dkj4linux I owe you a thanks- I have a working JL1 because I saw your thread here, and picked one up.

I managed to screw up the update to GRBL by not pressing the button before running update.exe.

I then got some help over at the LightBurn forum and managed to sort out recovering my JL1 with a $10 ebay STLINK-V2 programmer and a little fiddling about.

Thanks also to @vicious1 for keeping an open and supportive community here.

I’ll be looking at this thread for ideas about that Z lift- so again thanks to everyone for sharing.

Are these lasers no longer available?

It appears that they are not offered anymore, but this one is probably pretty close:

Amazon.com: Twotrees TTS-25 Laser Engraving Machine Laser Engraver, Wood Metal Laser Engraving Cutting Machine, DIY Laser Marking, Eye Protection Design, Easy Installation(50% Pre-Install)

It cost twice as much but looks like it might have a more powerful laser and a larger work area.

Mike

Thanks for the suggestion!

So I know this is a late reply, but, could there be a way to add something to z so this could be used For a drag knife for vinyl? It would be easier than using my mpcnc when I want to. I looked it up and it is horrible to laser pvc.

In order to make this work you would need to:

- Replace the control board with one that supports three drivers. The stock one only supports two drivers.

- Design and implement a simple Z axis.

This specific laser engraver is no longer available. It went out of stock, then came back in stock for a week or two, then out of stock again (since October). There are other cheap-ish laser engravers you could use as a basis, and I’ve seen visually similar engravers to this one elsewhere for $99 USD.

@RockinRiley & @robertbu what about attaching the drag knife to the end of a push-pull solenoid similar to this and using the air assist signal to extend or retract the blade?

Interesting idea to use a solenoid. if the solenoid will work (I have no idea about that), then you could connect it to the laser signal of the original board. Your drag knife jobs would have to be authored as laser jobs. You will need something to take the laser signal and switch the 12V power to the solenoid…mechanical relay, transistor, SSR…

After my last post I did a bit of searching for laser engravers. The cheapest I can find right now is $120 USD (purchsed on EBay and shipped from China).

air assist signal

I don’t see any available plugs on the board for this specific machine, so no air assist signal.

An alternative to a solenoid would be a servo, though that is going to require using a control board that has a servo pin available, and firmware support.

@Bigchepin Yes, i am open to anything. My question was, (I am not in my garage much with the cold) can the jl1 with grbl control something for the z? but yes, I am will to try that. Willing to try anything really.

I need to bring it in the house and see if there is an unused spot on the board I guess.

@robertbu ohh, never thought about that, that is a good idea too.