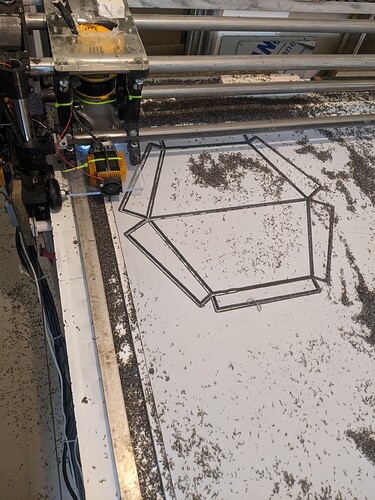

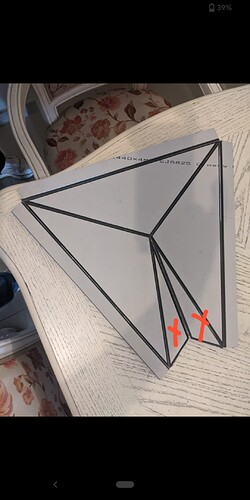

This is my first try of many (+15 designs already ready to cut)

How did the cuts go?

Despite the use of wood vbits because the acm 90° that doesnt have the tip wasnt available today it went perfect. It folded right away (but the tip caused some troubles easy fix but i didn’t wanted to damage a 3 week low use bit with a grinder to remove it) each corner was perfect. Im thinking about getting 2 vacuum pumps and make a vac holder for the panels with 16 zones in the table that should save me some time fixing the material, @jamiek idex build would be wonderful here , one router with a 1.00mm spiral and another with the v-bit…

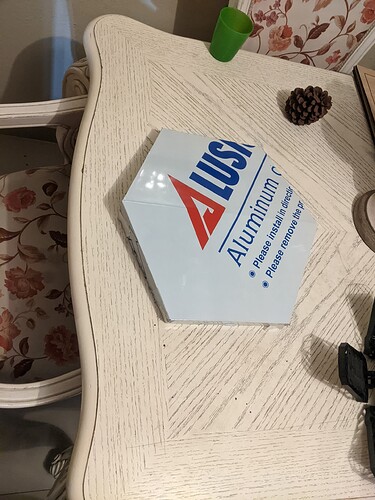

I assume that the panel is a 3mm with a .2 or thereabouts aluminium skin?

Its a 4mm one. (3mm are more expensive here)

Thanks, I’ve been considering making my LR3 struts from 3mm with folded flanges Not yet sure how tidy that will look. I have some panel in my stash of scrounged stuff and have been saving it for a few little CNC jobs but just haven’t got around to fiddling with it.

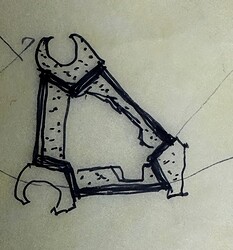

I have been advised to use a 3mm downcut (single flute) for the outline, as it happens I actually own a Panel Folding Bit which I ordered by mistake a few years ago so no need to modify a v-bit. ![]()

Not sure about any of the above, but you’ve got me a little excited.

Just follow Amana guidance by leaving a small amount of the plastic core in and get the acm vbit that have this profile: \ _ /

That is very cool. I have wanted to work with ACM. It seems like a decent mix between ease of milling and strength.

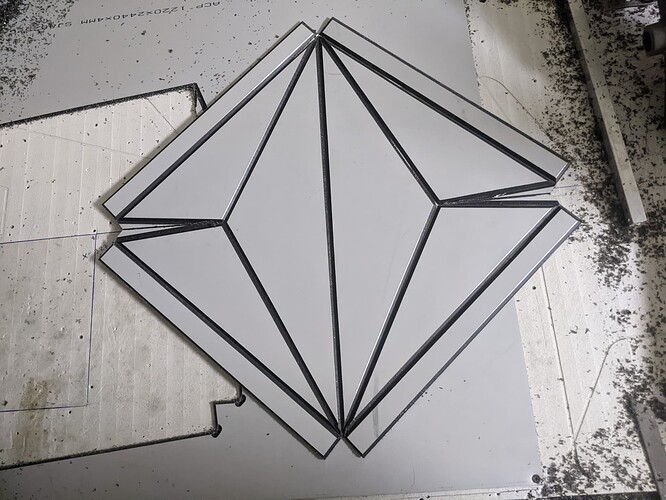

It is pretty easy if you know how to draw and align faces (make them flat) it is pretty much just like lasering card board for making boxes with a cnc

I need to get some of that. I love it.

As soon as you change the search from diabond to ACM, the prices are less than half. Need an origami 3D printer frame. One piece folder together LR beam?

Make a sketch with dimensions (mm use any decimal points as you need and send it to me i can do the final draw and unfold and send you a cut file.

In my country a Chinese acm sheet costs around usd$50.00 dibond or alucobond costs more than 130. Sure they don’t last as longer but dammmm

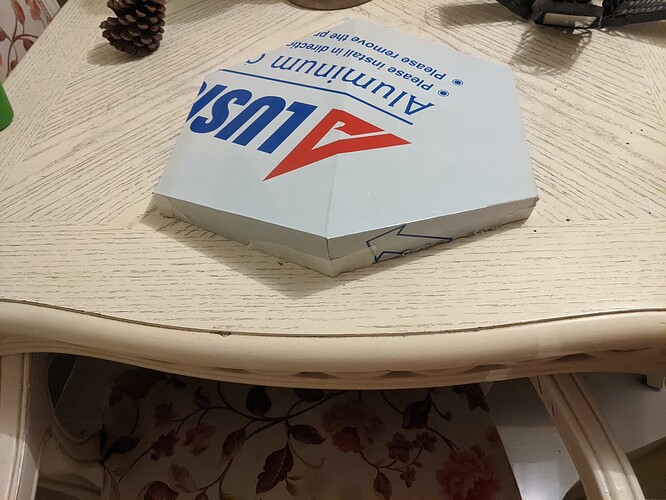

How do you join the mating pieces?

I know they fit nicely, but making a box needs overlaps. Or is there a trick to that?

The flaps marked with the red X, when you fold both ends and the whole piece you just use rivets os drywall screws. Be sure the borders align pretty neat on the painted side (i use some pressure clamps to hold it before i fix them

That is awesome!!

Just make sure your unfolded piece is under the sheet lenght

3mm is our local go-to product and there was once a mirror finished version and I’m so attracted to shiny things! (It’s not available any more sadly)

I have been mucking around for a very long time with the thought of using it for my LR beams. Initially I drew 10mm flanges along the top and bottom with cutouts for the braces, but I think even at 3mm it will be more than rigid enough so I will probably try that eventually.

Then I started folding bits of cardboard to see if I could make a continuous beam that would fit into the standard braces - it’s easy enough - if you just extend the flanges until they meet up they won’t fit over the corners, so they have to be oversized and creased so they can bend to pull the faces back into position.

I think it’s possible but the sequence of construction gets a bit “interesting”.

Draw it in SketchUp. Draw using mm. Iwill unfold it so you can cut it ( use the external vertices i will make you a cut file from the back of the sheet)