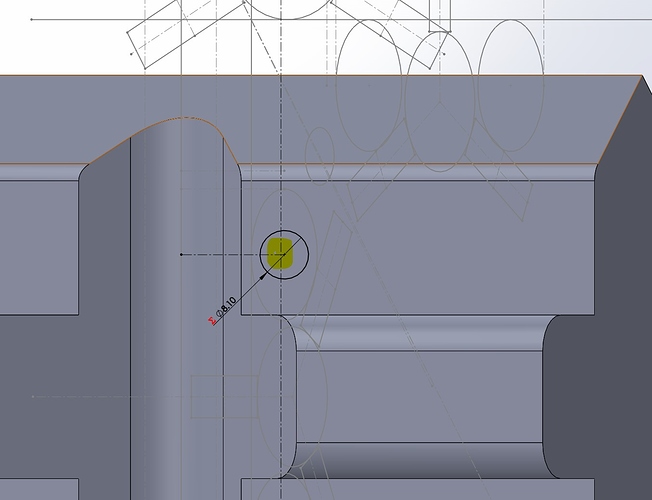

Frick…I found it.

The bolt holes are supposed to be on that dotted line, instead they are locked onto a sketch behind it. That makes them 0.2mm off on each side, and those holes spread the part at an angle so that is compounded. So the 3rd bearing is right, and we checked all those dimensions many times. Turns out the core holes are just too wide.