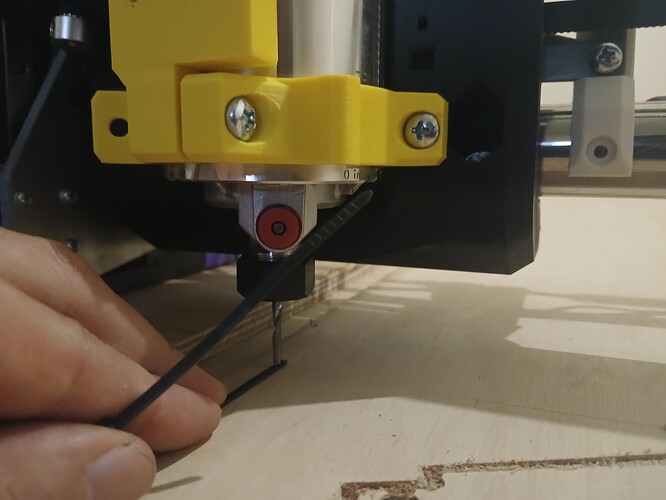

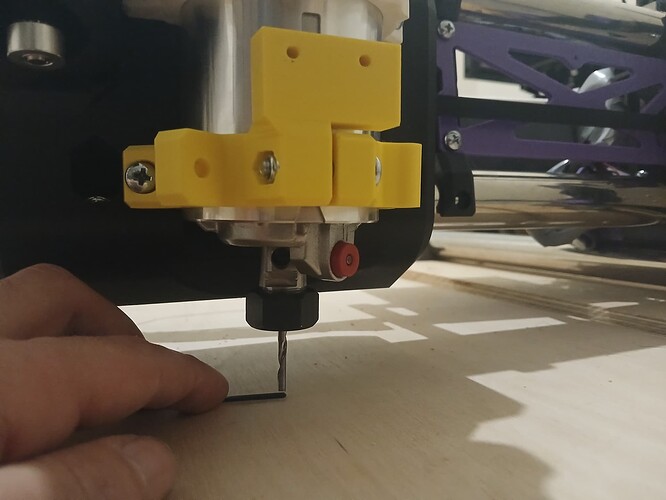

Hi, I’m trying to level the z axis because yesterday when i went to go cut the plywood for the strut plates and i noticed it’s lower on one end so it cut the piece unevenly(because I forgot to do it yesterday so doing it now as not to waste more material). I have been moving the bit a zip tie’s thickness above the material on one side then moving it over to the other end on the x axis and see how much difference there is and adjust the z pull off accordingly. I adjust the z axis motor 0 pull off to move it down but it doesn’t make a difference to either side.

I eventually set it to 50mm for the z axis motor 0 pull off, press set and the save macro and switched the machine on/off and it gave a an warning message [MSG:WARN:: pulloff_mm value 0.000 constrained to range (0.100,100000.000)]. it looks like it constrained it to 30mm but the z height is still the same across the whole x axis. What am I missing because I’m just moving it up and down on the x axis (I have a zip tie for a feeler gauge) and adding more and more to the z pull off and it’s not making a difference.

I’m literally following along the very last bit of the assembly and it says “Take the difference and adjust the side that moved furthest.” so I know that at least one side should move down or up in z axis when you adjust the pulloff for one of the z axis motors.

I feel so stupid for asking this because it seems so simple but it’s not making a difference and obviously i have to turn the machine On, connect to fluidNC move it to the other end of the x axis, measure with a gauge, adjust the pull off, home it, then move it back to measure again? in the assembly instructions it just says to use the save macro which is what I have been doing?